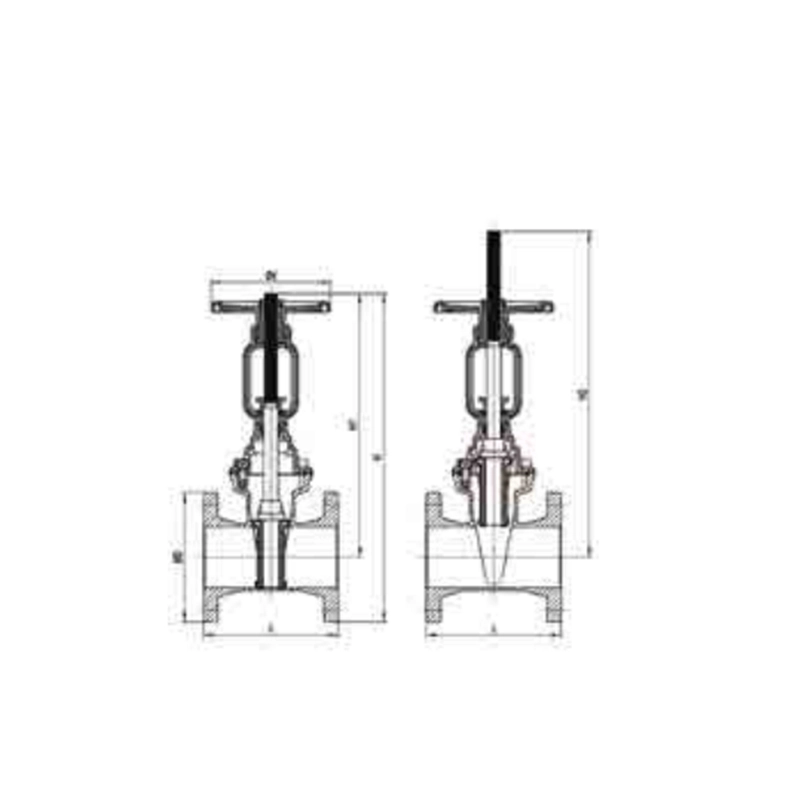

Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03

Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03 Definition and Components

OS & Y Type Gate Valve Definition & Main Parts

A Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03 is an industrial valve with Outside Screw and Yoke design and flanged connections. The "03" suffix typically indicates enhanced features or a specific pressure class. It combines visual stem position indication with resilient sealing.

Main Parts:

- Valve body with flanged ends

- Resilient-seated gate

- OS&Y assembly (yoke, rising stem, exposed threads)

- Handwheel mounted on yoke

- Adjustable gland packing

- Body-bonnet bolting and gasket

- Flange facing and bolt holes

Role, Characteristics, and Application Scenarios of Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03 in Pipelines

Fire gate valve Functions:

- Critical process line isolation

- Pump protection and control

- High-pressure system shutdown

- Steam and hot water service

Operational Features:

- Visual position indication via rising stem

- Packing adjustment/replacement under pressure

- Enhanced sealing for high-pressure applications

- Heavy-duty construction for industrial use

- Versatile flange options (ANSI, DIN, BS)

Typical Applications:

- Chemical processing plants

- Power generation facilities

- Oil & gas production

- Industrial heating systems

- High-pressure water networks

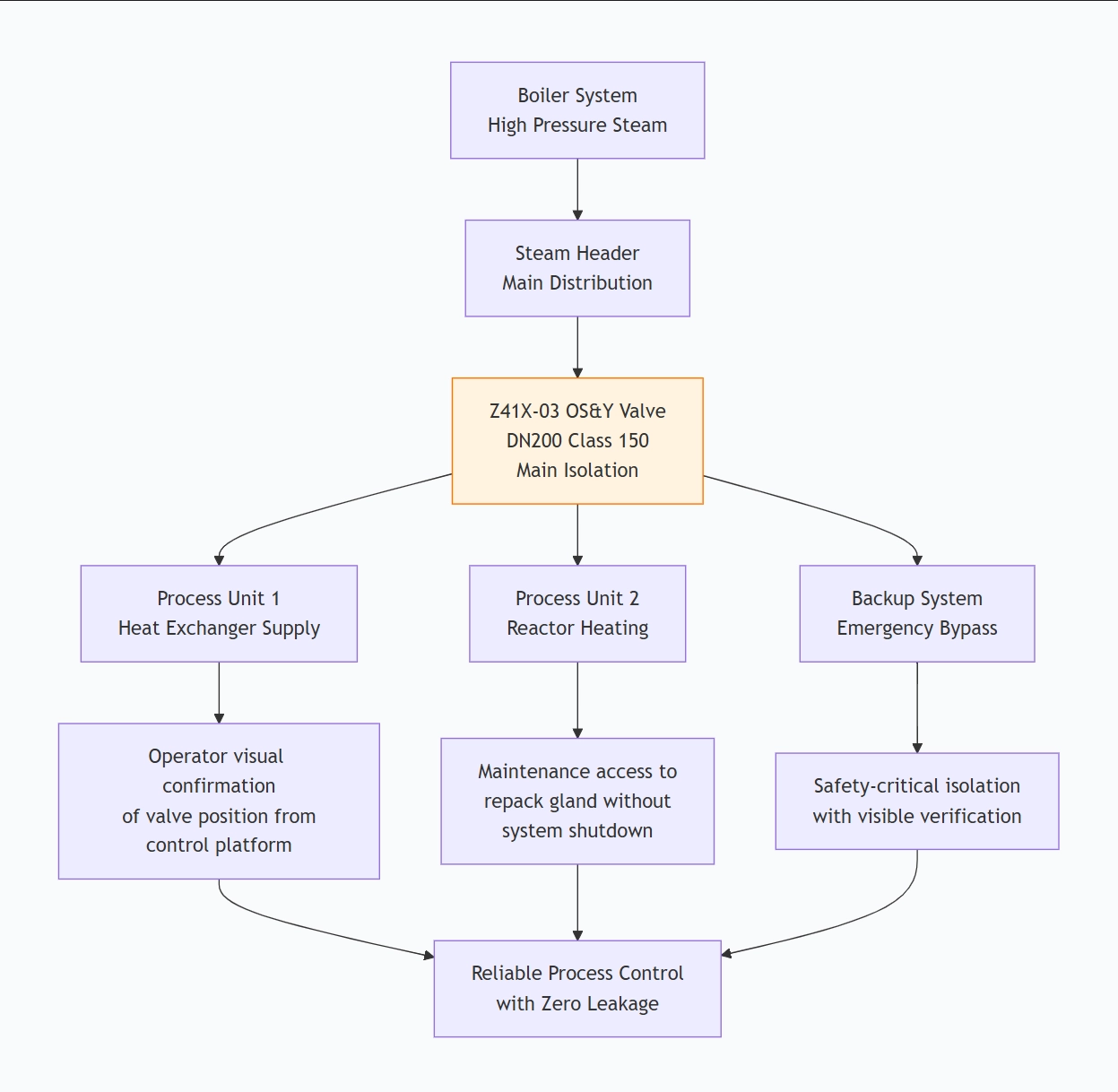

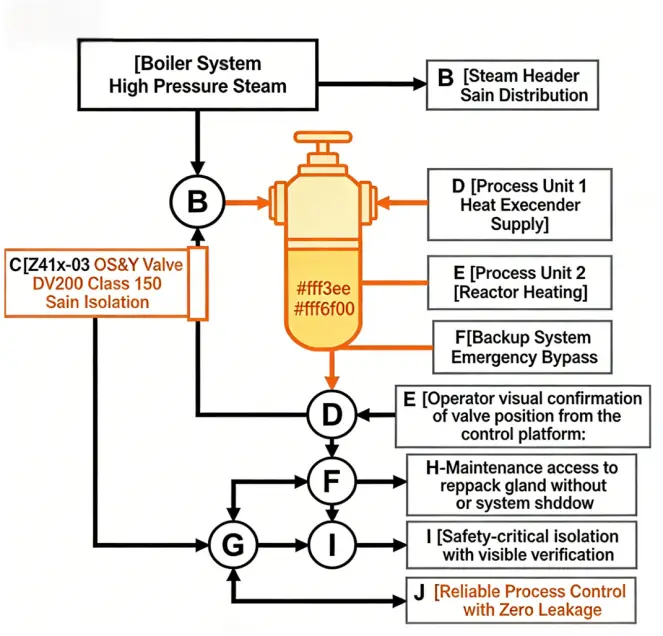

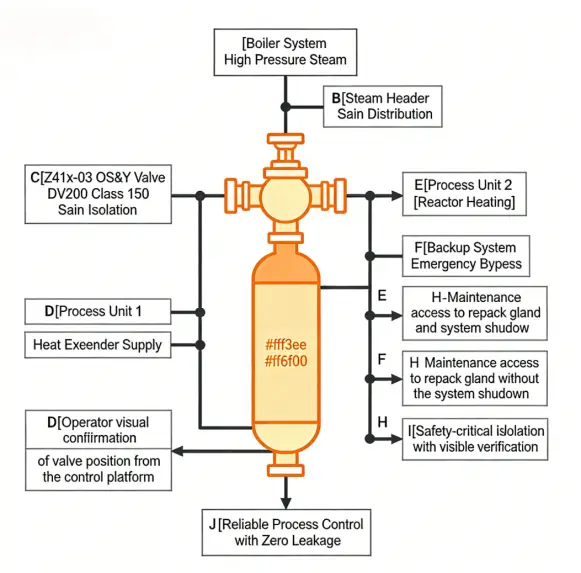

Scenario Diagram:

Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03 Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet: Carbon Steel ASTM A216 WCB or Ductile Iron ASTM A536

- Stem: Stainless Steel AISI 410/416

- Gate: Steel with EPDM or metal-seated options

- Yoke: Cast steel or ductile iron

- Packing: Graphite or braided for high temperature

Design Standards:

- API 600: Steel gate valves (if carbon steel body)

- ISO 10434: Bolted bonnet steel gate valves

- MSS SP-70: Cast iron gate valves

- Pressure classes: Class 150, 300 common

Connection Standards:

- Flanges: ANSI B16.5 (raised face) or ASME standards

- Face-to-Face: ANSI B16.10 dimensions

- Gaskets: Spiral wound, ring type, or full-face

- Bolting: ASTM A193/A194 for high temperature

How to Select Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03

Fire valve Key Steps:

- Define Service Conditions: Temperature, pressure, media

- Select Materials: Based on corrosion and temperature requirements

- Specify Standards: API, ANSI, or ISO compliance needed

- Choose Supplier: Industrial valve specialists

- Review Testing Requirements: NDT, special testing if needed

Critical Specifications:

- Pressure-temperature rating

- End connections (RF, FF, RTJ)

- Trim material (standard or special)

- Packing material (standard or high-temp)

- Actuator mounting (ISO 5211)

Important Considerations:

- High-temperature seat options if needed

- Cryogenic service modifications if required

- Fire-safe design requirements

Pre-Shipment Inspection for Export Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-03 and Key Considerations

Documentation Check:

- Material Test Reports (ASTM compliance)

- NDT reports if specified (RT, UT, MT, PT)

- Pressure test certificates

- Heat treatment certificates if applicable

- Special compliance certificates (NACE, PED)

Physical Inspection:

OS&Y Function Verification

Smooth stem operation through full travel

Proper yoke-stem alignment

Thread condition and lubrication

Backseat function test

High-Pressure Features

Bolted bonnet integrity

Stud/nut quality and tightening

Gasket seating surface condition

Pressure boundary verification

Pressure Testing

Shell test: 1.5 × pressure class

Seat test: 1.1 × pressure class (both directions)

High-pressure hold test if specified

Packing leakage test

Special Service Checks

Fire-safe testing if required

Low-temperature impact tests if applicable

Special coating verification

Traceability markings

Export Packaging:

- Heavy-duty crating for industrial valves

- Flange protectors (steel preferred)

- Stem thread protection (heavy-duty caps)

- Moisture barrier for sea transport

- Lifting lugs clearly marked

- Component separation for large valves

Key Precautions:

- High-value items: Consider insurance and tracking

- Heavy components: Professional rigging and handling

- Temperature-sensitive materials: Climate-controlled storage if needed

- Corrosion protection: Extra VCI for marine environments

- Documentation security: Keep original certificates separate

Final Shipping Documents:

- Commercial Invoice with detailed specifications

- Packing List with weights and dimensions

- Bill of Lading

- Certificate of Origin

- Complete technical dossier (certs, reports, drawings)

- Installation, Operation & Maintenance Manual

.png)

.png)