Wafer Butterfly Valve with Tamper Switch

Wafer Butterfly Valve with Tamper Switch Definition and Components

A Wafer Butterfly Valve with Tamper Switch Model No. XD371X is a compact, quarter-turn on/off valve primarily used in fire protection systems (sprinkler and deluge systems). The designation "XD371X" typically indicates a specific manufacturer's model for a lugged or wafer-style butterfly valve with a resilient seat and an integral supervisory switch.

Key Terminology:

- Wafer Style:The valve body is designed to be "clamped" between two pipeline flanges using through-bolts, making it lightweight and space-saving.

- Tamper Switch (Supervisory Switch):An electrical device mounted on the valve stem that monitors the valve's position. It sends a signal to a fire alarm control panel (FACP) if the valve moves from its normal, open position, indicating unauthorized closure.

- Butterfly Valve:Flow is regulated by a disc rotating 90 degrees within the pipe bore.

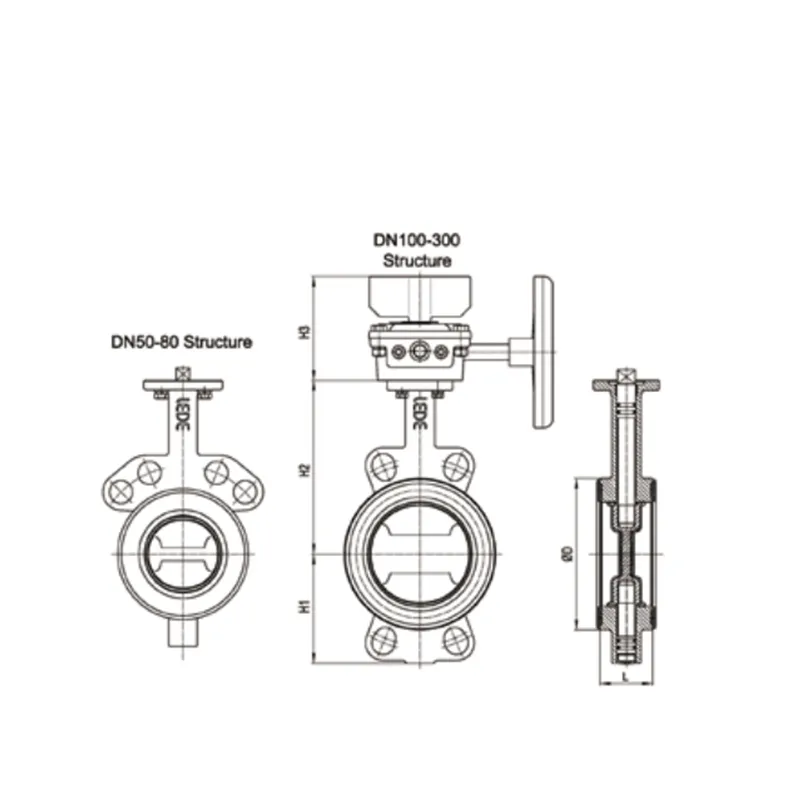

Butterfly Valve for Fire Protection Main Parts:

1.Valve Body (Wafer or Lugged design)

2.Disc (The "butterfly," often ductile iron with epoxy coating)

3.Stem (One-piece or two-piece, connecting disc to actuator)

4.Resilient Seat (EPDM or Nitrile, bonded or mechanically locked in the body)

5.Actuator / Gear Operator (Manual lever, gearbox, or electric/pneumatic actuator)

6.Tamper Switch Assembly:

Switch Housing (Weatherproof enclosure)

Actuating Cam (attached to the stem)

Micro-Switch (SPDT or DPDT)

Conduit Connection

7.Seals and Bushings (Stem seals, bushings)

Role, Characteristics, and Application Scenarios of Wafer Butterfly Valve with Tamper Switch in Pipelines

Functions:

- Flow Isolation:On/Off control of water in a pipeline.

- Supervision:Continuous monitoring of valve position for life safety compliance.

- Alarm Indication:Sends a "trouble" or "supervisory" signal to the FACP upon unauthorized operation.

Fire Protection Butterfly Valves Operational Features:

- Quick 90° Operation:Lever or gear operator allows fast opening/closing.

- Compact & Lightweight:Easy to install in tight spaces compared to gate valves.

- Supervisory Circuit:The switch is typically normally closed (NC) or normally open (NO) in the valve's normal position (open). A change in position breaks the circuit, triggering the supervisory signal.

- Visual Position Indicator:Lever aligned with pipe = OPEN; lever perpendicular = CLOSED.

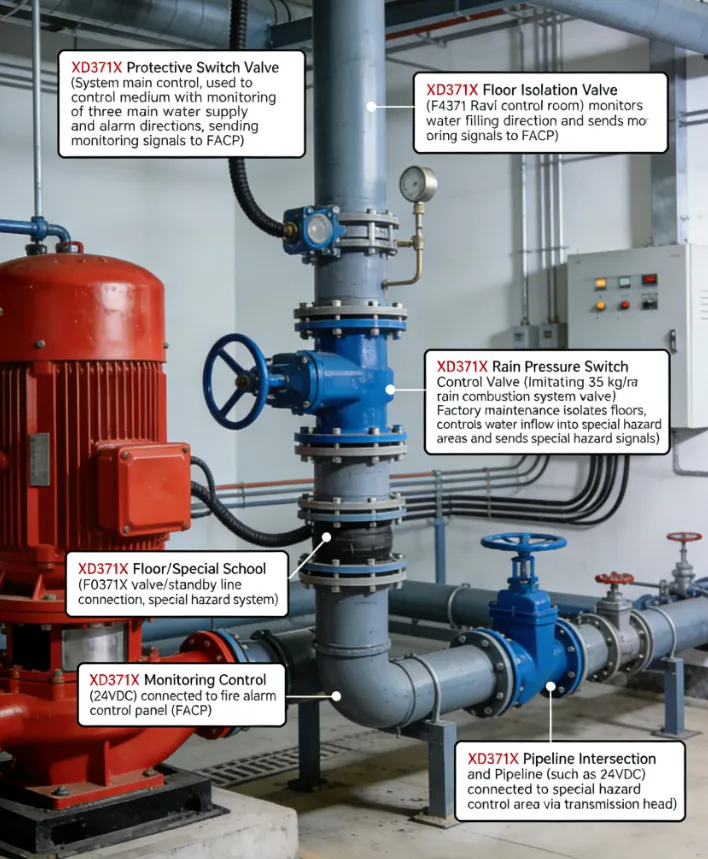

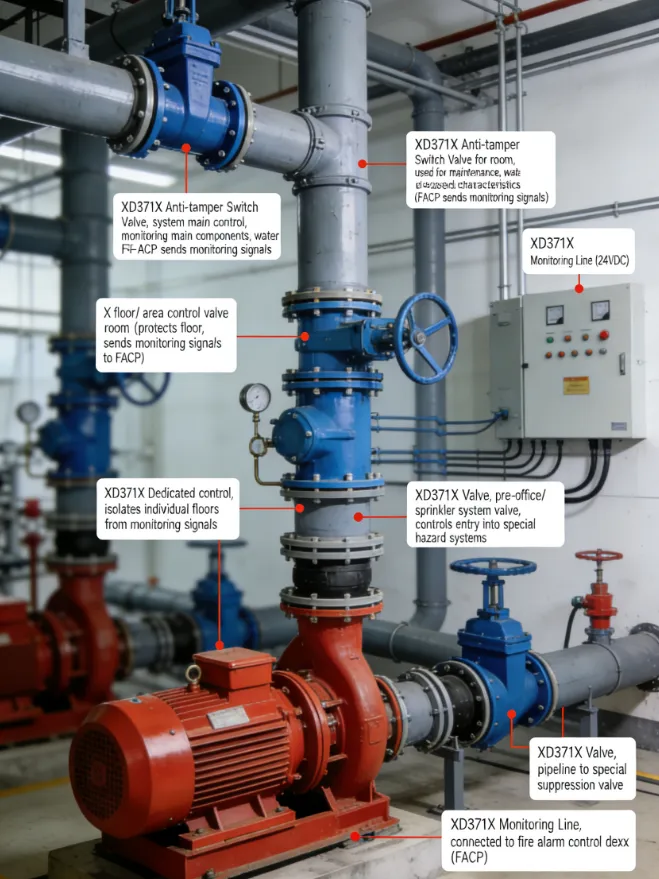

Primary Usage Scenarios:

This valve is mandatory in fire sprinkler systems per NFPA 13 and other life safety codes to prevent unintentional valve closure.

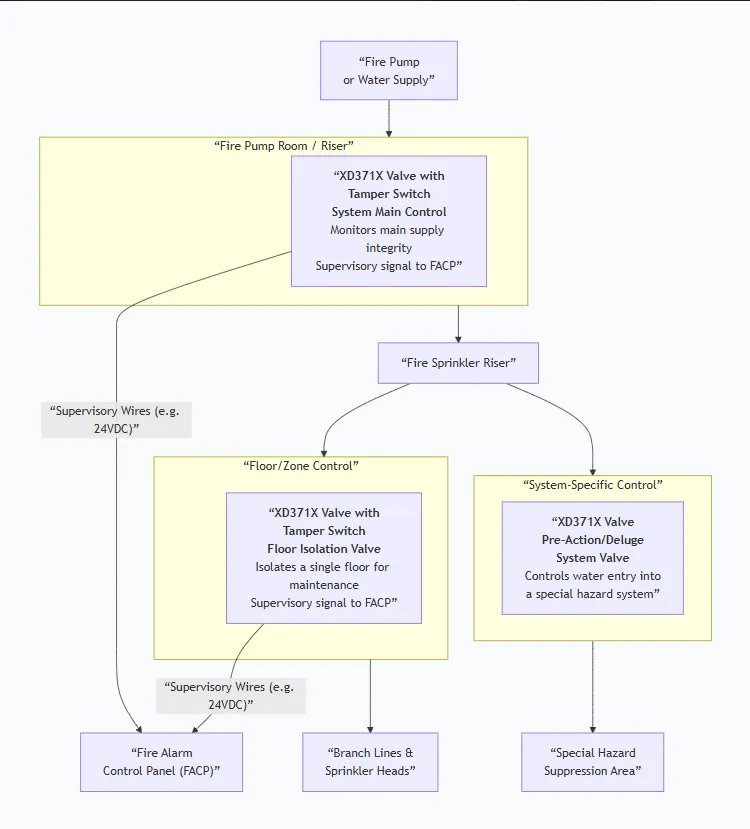

Scenario Diagram:

Wafer Butterfly Valve with Tamper Switch Standards: Materials, Design, and Connections

How to Select Wafer Butterfly Valve with Tamper Switch

Step 1: Define Detailed Specifications

Create a technical specification focusing on fire protection requirements:

- Size & Pressure:Nominal Diameter (e.g., 8") and Pressure Rating (e.g., 175 psi or Class 150).

- Standards & Listing:Crucially state: "Valve must be UL 1091 Listed and/or FM Approved for fire protection service."

- Materials:Specify ductile iron body/disc, stainless steel stem, EPDM seat (for water).

- Tamper Switch:Specify electrical ratings (e.g., SPDT, 5A, 24-240V AC/DC), enclosure rating (NEMA 4X), and conduit entry size.

- Actuator:Manual lever with locking handle, or gear operator for large sizes.

Step 2: Source and Evaluate Suppliers

- Source from manufacturers specializing in UL/FM listed fire protection valves.

- Require submittals including: UL/FM listing certificates, cut sheets, wiring diagram for the switch, and dimensional drawings.

- Key Evaluation Criterion:Proof of listing for the exact model being supplied. Non-listed valves are not acceptable for code-compliant fire systems.

Step 3: Quality Assurance & Logistics

- For large projects, consider Factory Witness Testing of the valve and switch operation.

- Clarify packaging to protect the exposed switch mechanismduring shipment.

Pre-Shipment Inspection for Export Valves and Key Considerations

Inspection Checklist:

Fire Valve Key Precautions for Export:

- Moisture Protection for Electronics:Seal the switch housing and include silica gel desiccant in the valve/packaging to prevent condensation damage.

- Impact Protection:Use custom foam or cardboard to protect the projecting tamper switch assembly from being snapped off. Consider a dedicated wooden crate for larger valves.

- Position Locking:The valve must be shipped in the FULL OPEN position, with the lever/gear locked if possible.

- Separate Accessories:Pack any optional switch kits, locks, or special tools in a marked bag inside the main crate.

- Documentation:Include the UL/FM guide card and installation/wiring manual in a waterproof pouch attached to the crate interior.

Wafer Butterfly Valve with Tamper Switch Size Chart

.png)

.png)