Grooved Y Strainer

Grooved Y Strainer Definition and Components

A Grooved Y Strainer Model No. 6102 is a pipeline filtration device designed for the mechanical removal of solids from flowing fluids, engineered for rapid installation and maintenance within grooved piping systems. The model number signifies it is the grooved-end variant of a common Y-strainer product line (where 6101 is typically flanged).

Y Strainer with Valve Key Terminology:

- Grooved Ends:The body features precision-machined circumferential grooves at each end that accept a grooved coupling (a housing and a rubber gasket). This allows for a bolted connection without threading or welding.

- Y Strainer:The body is shaped like a "Y," with the straining element set in the angled branch. This design allows debris to be collected in the sump with minimal impact on straight-through flow.

Fire Fighting Valves Types Main Parts:

- Body: Cast housing (typically ductile iron or cast iron) in a "Y" shape with grooved ends.

- Cover/Cap: Removable end (threaded or bolted) that seals the strainer chamber and provides access to the screen.

- Screen (Strainer Basket): A perforated or mesh cylinder that captures debris. It is the key functional component.

- Gasket: Seals the joint between the body and the cover.

- Blow-Off/Drain Connection: A tapped opening at the bottom of the screen chamber, usually fitted with a plug or a small valve for draining collected debris.

- Grooved Ends: Machined grooves that comply with industry standards for grooved coupling engagement.

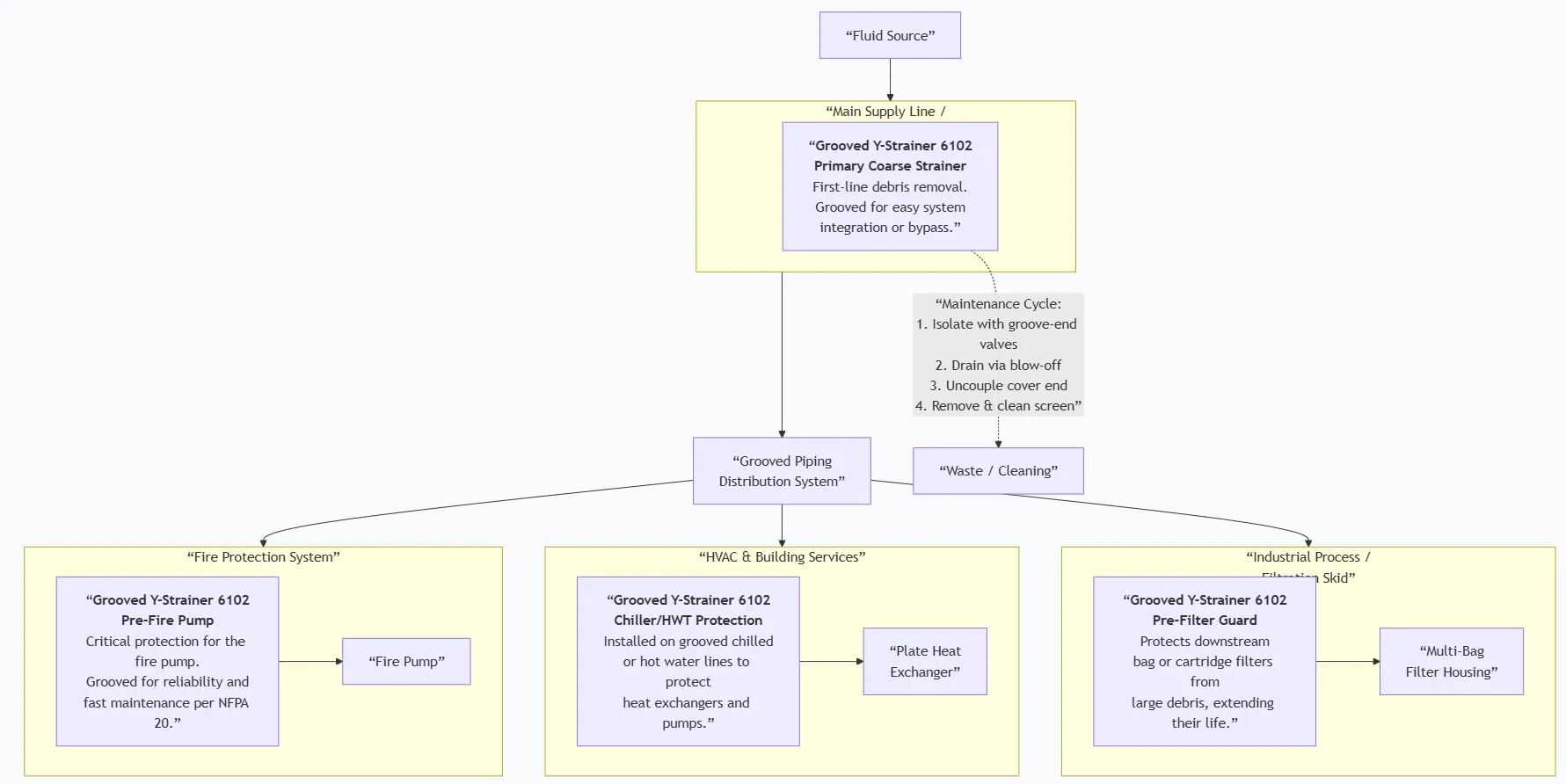

Role, Characteristics, and Application Scenarios of Grooved Y Strainer in Pipelines

Y Strainer Valve Functions:

- Particle Filtration:Protects downstream equipment (pumps, control valves, meters, nozzles) by trapping pipeline scale, weld slag, and other debris.

- System Integrity Maintenance:Helps maintain clean process fluid and prevents particulate-related blockages or wear.

Operational Features:

- Fast Installation/Service:Grooved connections enable much quicker installation or removal for screen cleaning compared to flanged or welded systems.

- Low Pressure Drop:The "Y" design and appropriate screen selection minimize flow restriction.

- Direction-Sensitive:Must be installed with the screen leg pointing downward. An arrow indicates the correct flow direction.

- In-line Servicing (with valving):Can be isolated and serviced without disturbing the main pipeline if installed between isolation valves.

- Requires Monitoring:Pressure drop across the strainer will increase as the screen collects debris, signaling the need for cleaning.

Primary Usage Scenarios:

Ideal for systems where modularity, quick installation, and ease of maintenance are priorities. Common in fire protection, HVAC, industrial process water, and temporary or frequently modified piping systems.

Scenario Diagram:

Grooved Y Strainer Standards: Materials, Design, and Connections

| Standard Type | Primary Standard(s) | Purpose & Key Specifications |

| Grooved Connection | ANSI/AWWA C606 | The essential standard for Grooved and Shouldered Joints, defining dimensions, tolerances, and assembly. |

| General Design & Pressure | ASME B16.34 / ASME BPVC Section VIII | Referenced for pressure design of the body. Many manufacturers design per ASME Boiler & Pressure Vessel Code rules. |

| Material Standards | ASTM A536 (Ductile Iron) - Common. | Ductile iron is preferred for grooved components due to its higher strength and impact resistance. |

| ASTM A126 (Gray Iron) - Less common for grooves. | ||

| ASTM A276 Type 304/316 (Stainless Steel Screen) | ||

| ASTM D2000 (Elastomer Gaskets) | ||

| Fire Protection Service | UL 603 / FM 1920 (Couplings) | For fire pump applications, the grooved components should be listed. NFPA 20 mandates a strainer on the pump suction. |

| NFPA 20 (Fire Pumps) | ||

| Face-to-Face | Manufacturer's Standard | While not a flange, manufacturers often adhere to a standard face-to-face length for interchangeability. |

How to Select Grooved Y Strainer

Step 1: Define Precise Specifications

Groove compatibility is the critical differentiator from flanged strainers.

- Service Conditions:Fluid, temperature, design pressure (e.g., 175 psi, 300 psi).

- Size & Groove Spec:Nominal Diameter (e.g., 6") and exact Groove Compatibility. State: "Grooved ends to match [Coupling Brand, e.g., Victaulic] Style [e.g., 77], per AWWA C606."

- Screen Specification:Define the screen mesh or perforation size (e.g., "3.2mm (1/8") perforations" or "30 mesh"). This is based on the protection requirements of downstream equipment.

- Materials:Body (e.g., Ductile Iron), Screen (e.g., SS304), Gasket (e.g., EPDM).

- Drain Connection:Size and type (e.g., 3/4" NPT plug or ball valve).

Step 2: Source from Specialized Suppliers

- Source from suppliers specializing in grooved piping systems or general valve distributors with strong grooved product lines.

- Request a dimensional drawingconfirming groove details and overall length.

- Verify that the strainer's pressure rating is compatiblewith the rating of the grooved couplings you will use.

Step 3: Order Execution

- These are standard catalog items. Confirm lead times.

- Required documents: Commercial Invoice, Packing List, Certificate of Compliance. MTRs for the body material are recommended for quality assurance.

Pre-Shipment Inspection for Export Grooved Y Strainer and Key Considerations

Inspection Checklist:

| Category | Check Point | Acceptance Criteria |

| Documentation | 1. Packing List & Compliance Cert. | Must list correct model, size, and quantity. |

| 2. Dimensional Drawing | Verify groove specs and face-to-face length. | |

| Physical/Functional | 3. Groove Inspection | CRITICAL: Grooves must be clean, smooth, and free of burrs, cracks, or machining defects. Dimensions should be verified with a groove gauge. |

| 4. Screen Inspection | Screen must be intact—no broken perforations or mesh wires. Material should be as specified (e.g., stainless steel). | |

| 5. Cover Operation | Cover should thread or bolt on smoothly and seal evenly without cross-threading. | |

| 6. Cleanliness | Internal cavity and screen must be free of sand, metal chips, oil, and grease. | |

| 7. Markings | Body should be marked with size, pressure rating (if applicable), and flow direction arrow. | |

| Packaging | 8. Groove End Protection | Must have threaded, rigid plastic or metal protective caps designed for grooved pipe. Taped cardboard is unacceptable. |

| 9. Screen & Cover Protection | The screen should be wrapped separately or the strainer packed to prevent internal damage. The cover should be securely attached or separately packed. |

Key Precautions for Export:

- Mandatory Hard Cap Protection:The precision-machined grooves are easily damaged. Screw-on rigid caps are non-negotiable for sea freight. These caps protect both the grooves and the sealing surfaces.

- Internal Component Securement:If the screen is installed, ensure it is centered and the strainer is packed in a position (usually upright) that prevents the screen from being dislodged and damaged during transit.

- Desiccant for Internal Cavity:Place a desiccant (silica gel) bag inside the strainer body before sealing the caps to prevent condensation and internal corrosion.

- Crating for Odd Shape:The "Y" shape can make crating awkward. Use a well-braced wooden crate that fully supports the body and protects the protruding screen leg from impact.

- Clear Handling Instructions:Mark the crate with "Protective Caps Must Remain Installed Until Ready for Assembly" and "Keep Upright" to ensure proper handling.

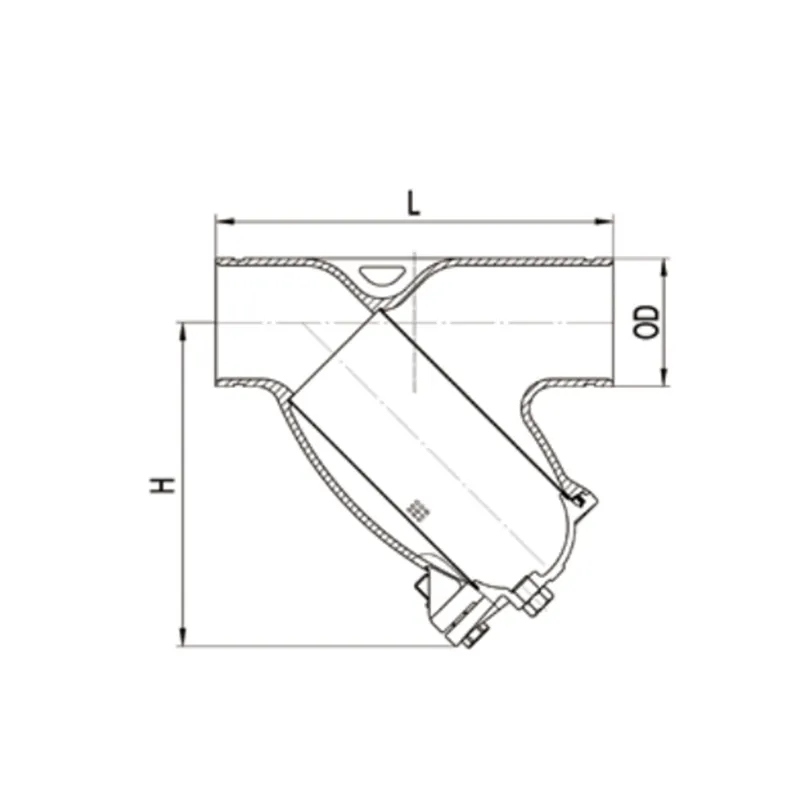

Grooved Y Strainer Size Chart

| Dimensions | Pressure rating | Size(mm) | |||

| DN | inch | psi | OD | L | H |

| 50 | 2 | 362

|

60.3 | 230 | 154 |

| 65 | 2.5 | 362 | 73 | 290 | 201 |

| 76.1 | |||||

| 80 | 3 | 362 | 88.9 | 310 | 210 |

| 100 | 4 | 362 | 114.3 | 350 | 269 |

| 125 | 5 | 362 | 139.7 | 400 | 320 |

| 141.3 | |||||

| 150 | 6 | 362 | 165.1 | 480 | 357 |

| 168.3 | |||||

| 200 | 8 | 362 | 219.1 | 550 | 442 |

.png)

.png)