Dry Alarm Check Valve

Dry Alarm Check Valve Definition and Components

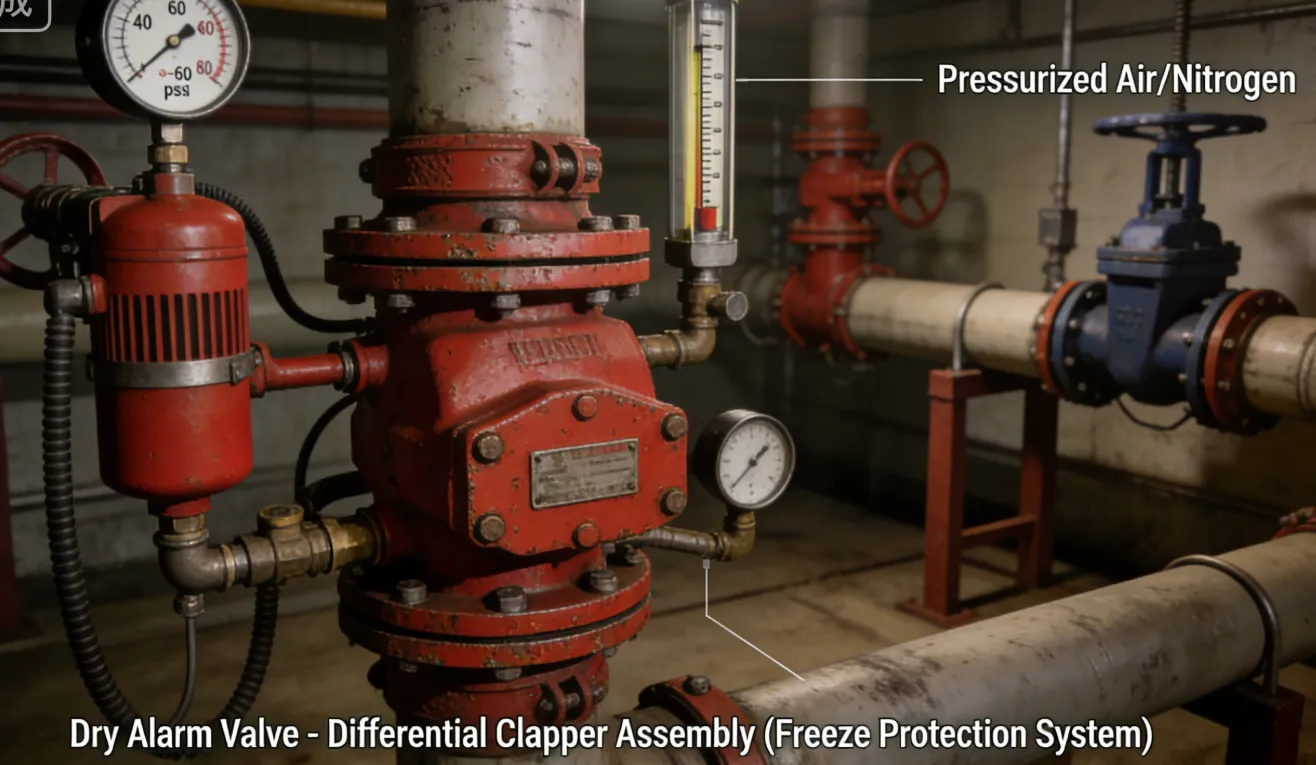

A Dry Alarm Check Valve is the central control assembly for a dry-pipe fire sprinkler system. It is a specialized, differential-type valve that keeps water out of the system piping (which is filled with compressed air or nitrogen) until a sprinkler activates. Upon activation, it releases the air, allows water to enter, and triggers an alarm.

Key Terminology:

- Dry:For use in "dry-pipe" systems where the piping is filled with compressed air or nitrogen to prevent freezing.

- Differential Design:The valve clapper is designed with a larger surface area on the air (system) side than the water (supply) side. A small amount of "priming water" creates a seal, and the higher air pressure holds the clapper tightly closed against the incoming water pressure.

- Alarm:Incorporates ports that activate alarms when air pressure drops and water begins to flow.

Main Parts:

- Main Valve Body: Houses the differential clapper assembly.

- Differential Clapper & Seat: The core mechanism. A rubber-faced clapper with a larger diameter on the top (system side) than the bottom (supply side).

- Priming Water Reservoir: The space above the clapper is filled with a small amount of water to create an airtight seal.

- Air Pressure Gauge: Monitors the supervisory air pressure in the system piping (typically 20-40 psi).

- Water Pressure Gauge: Monitors the incoming water supply pressure.

- Intermediate Chamber (Alarm Port): A chamber between the clapper seat and the alarm line. When the clapper opens, water rushes into this chamber.

- Trim (Piping) Assembly: Includes the priming water level check valve, alarm line valve, drain valves, and connections for the air supply (exhauster/maintenance device).

- External Reset Mechanism: A handwheel or lever to manually reset the clapper after operation.

Role, Characteristics, and Application Scenarios of Dry Alarm Check Valve in Pipelines

Functions:

- System Sealing: Maintains a reliable air/water seal to prevent water from entering the dry piping.

- Quick Opening: Rapidly opens when air pressure drops to minimize water delivery time.

- Alarm Activation: Triggers hydraulic (water motor gong) and electrical (pressure switch) alarms upon water flow.

- System Reset: Allows the system to be drained, reset, and re-pressurized with air after operation.

Operational Features:

- Differential Principle: A small, constant air pressure (e.g., 20 psi) can hold back a much higher water pressure (e.g., 100 psi) due to the clapper's area differential.

- "Water Delivery Time" is Critical: Dry systems have a maximum allowable time for water to reach the most remote sprinkler (per NFPA 13). Valve design and system size are optimized for this.

- Priming Water Seal: Requires maintenance to ensure the proper water level is maintained to prevent air leakage past the clapper.

- More Complex than Wet Valves: Requires an air maintenance compressor or nitrogen supply and more involved testing.

Fire Sprinkler Alarm Check Valve Primary Usage Scenarios:

Used as the main control valve for dry-pipe fire sprinkler systems in unheated areas where water in the pipes would freeze (e.g., parking garages, warehouses, attics, freezers, loading docks).

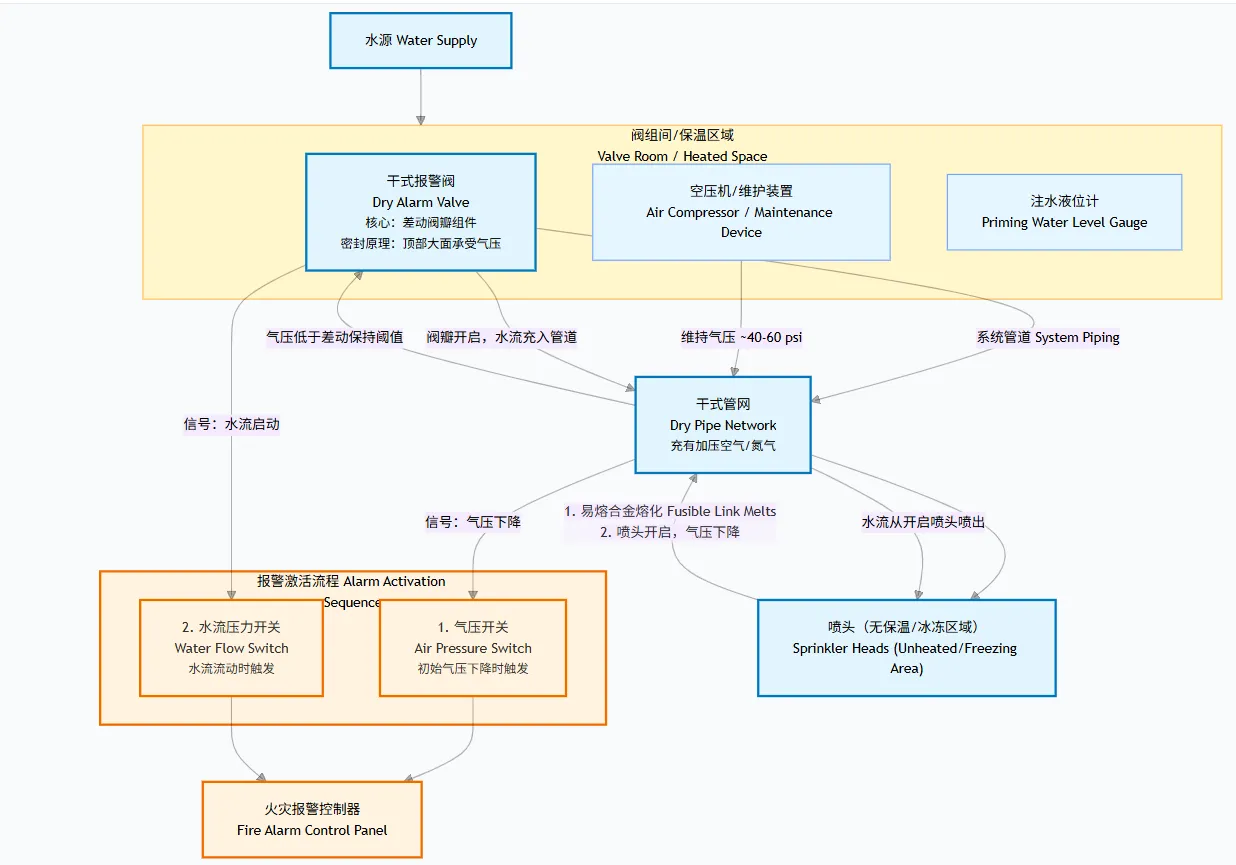

Scenario Diagram:

Dry Alarm Check Valve Standards: Materials, Design, and Connections

| Standard Type | Primary Standard(s) | Purpose & Key Specifications |

| Design & Performance | UL 260 / FM 1110 | The essential listing standards for Dry Pipe Alarm Valves in North America. These standards validate the valve's operational timing and reliability. |

| Fire System Code | NFPA 13 | Dictates the installation requirements, including maximum water delivery time, air pressure settings, and valve sizing for dry systems. |

| Material Standards | ASTM A126 Class B (Gray Iron Body). | Materials must withstand corrosive priming water and varying temperatures. |

| ASTM A536 (Ductile Iron) for higher durability. | ||

| ASTM B584 (Bronze) for trim valves. | ||

| Stainless Steel for clapper shaft and springs. | ||

| Connection Standards | ASME B16.1 Class 125/250 (Flanged) - Standard. | Flanged connections prevail. Sizes commonly range from 2" to 8" based on system hydraulic calculations. |

| AWWA C110 (Ductile Iron Flanges). | ||

| Air Supply | NFPA 13 | Governs the requirements for the air/nitrogen maintenance equipment (compressors, air dryers, regulators). |

How to Select Dry Alarm Check Valve

Step 1: Define Specifications from System Design

The valve is specified by the fire protection engineer based on complex calculations.

- Size & Orifice:Determined by hydraulic calculations to meet water delivery time Specify the orifice size (e.g., 1", 1-1/4") which is critical for dry valve performance.

- Listing Requirement:Must specify: "UL 260 Listed and/or FM Approved Dry Pipe Alarm Valve."

- Pressure Ratings:Specify both maximum water working pressure and maximum air working pressure.

- Trim & Accessories:Specify required trim (priming check valve, alarm line valve, drains) and required gauges. The Air Maintenance Device (compressor, air dryer, low-pressure switch) is typically a separate but coordinated purchase.

- Connection Type:Flanged, per riser diagram (e.g., ASME B16.1 Class 125).

Step 2: Source from Fire Protection Specialists

- Purchase only from authorized distributors of major fire protection manufacturers (e.g., Victaulic/Viking, Tyco, Reliable).

- Require a complete submittal package, including: UL/FM listing sheets, detailed dimensional drawings, water delivery time charts, and a schematic of the recommended trim.

- The engineer must review and approvethe submittal, ensuring the selected valve meets the calculated system demand.

Step 3: Order Execution

- The purchase order must reference the approved submittals.

- Consider lead times, as dry valves are less common than wet valves and may not be standard stock.

Pre-Shipment Inspection for Export Dry Alarm Check Valve and Key Considerations

Inspection Checklist:

| Category | Check Point | Acceptance Criteria |

| Documentation | 1. UL/FM Listing Mark | Permanently affixed to the valve body. |

| 2. Listing Documentation | Official guide card or report for the specific model and orifice size. | |

| 3. Hydrostatic & Air Test Certificates | Proof of shell/seat pressure tests and functional air hold test. | |

| Physical/Functional | 4. Clapper & Seat Condition | Inspect the differential clapper face and seat for imperfections. The sealing surface must be flawless. |

| 5. Priming Water Check Valve | This small valve must operate freely to maintain the proper water level. | |

| 6. Internal Cleanliness & Dryness | CRITICAL: The valve interior and all internal passages must be completely dry to prevent freezing damage during transit. | |

| 7. Gauges & Trim Valves | All should be closed and protected. Gauges are best removed and packed separately. | |

| Packaging | 8. Clapper Securement | The clapper must be mechanically blocked or strapped in the closed position to prevent damage during shipping. |

| 9. Moisture Prevention | Desiccant (Silica Gel) bags must be placed inside the valve body and all pipe openings. Openings should be sealed with waterproof tape and caps. |

Fire Valves Key Precautions for Export:

- Extreme Dryness is Non-Negotiable:After final testing, the valve must be thoroughly blown dry with compressed air and immediately sealed. Residual moisture will freeze and cause costly damage.

- VCI Protection:Use Vapor Corrosion Inhibitor (VCI) powder or spray inside the valve body to protect ferrous components from rust during ocean transit.

- Protect the Clapper Seat:The precision-machined seat is easily damaged. The shipping block must prevent any impact or vibration from causing the clapper to chatter against the seat.

- Separate Crate for Accessories:Pack sensitive accessories like the Air Maintenance Device, pressure switches, and gauges in their own, cushioned boxes. Do not leave them installed.

- Clear Documentation:Include a waterproof pouch inside the main crate containing the installation manual, test reports, listing card, and a specific warning about ensuring the valve is dry before storage or installation.

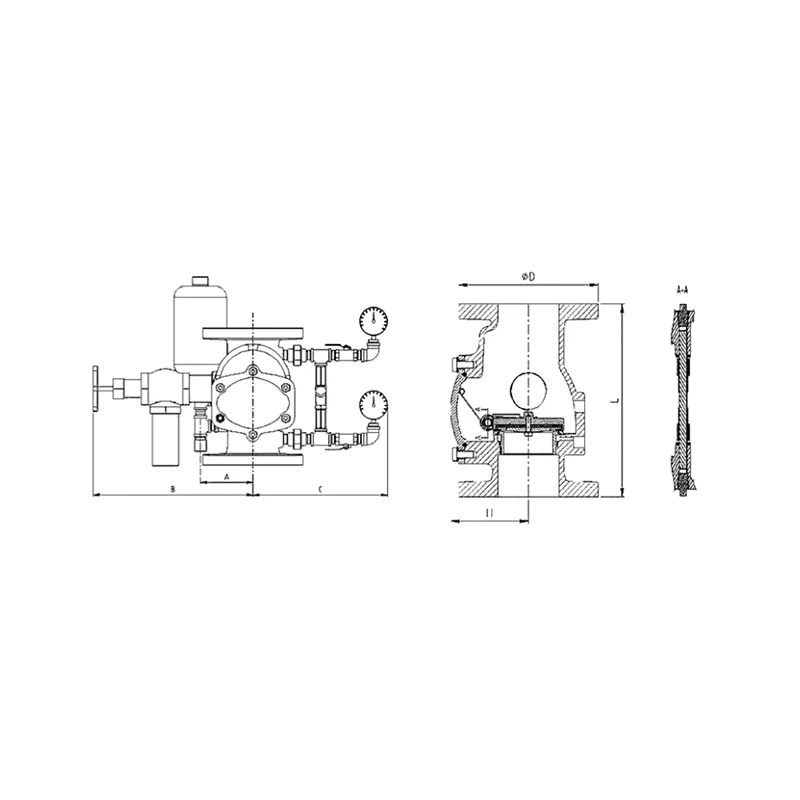

Dry Alarm Check Valve Size Chart

| Dimensions | Pressure rating | Size(mm) | |||||||

| DN | inch | psi | Φ D

|

L | H | A | B | C | E |

| 80 | 3 | 300 | 190 | 283 | 120 | 120 | 296 | 300 | 238 |

| 100 | 4 | 300 | 229 | 305 | 127.5 | 120 | 365 | 305 | 182 |

| 150 | 6 | 300 | 280 | 394 | 182 | 120 | 402 | 330 | 218 |

| 200 | 8 | 300 | 345 | 457 | 214 | 120 | 424 | 365 | 248 |

.png)

.png)