Water Motor Gong

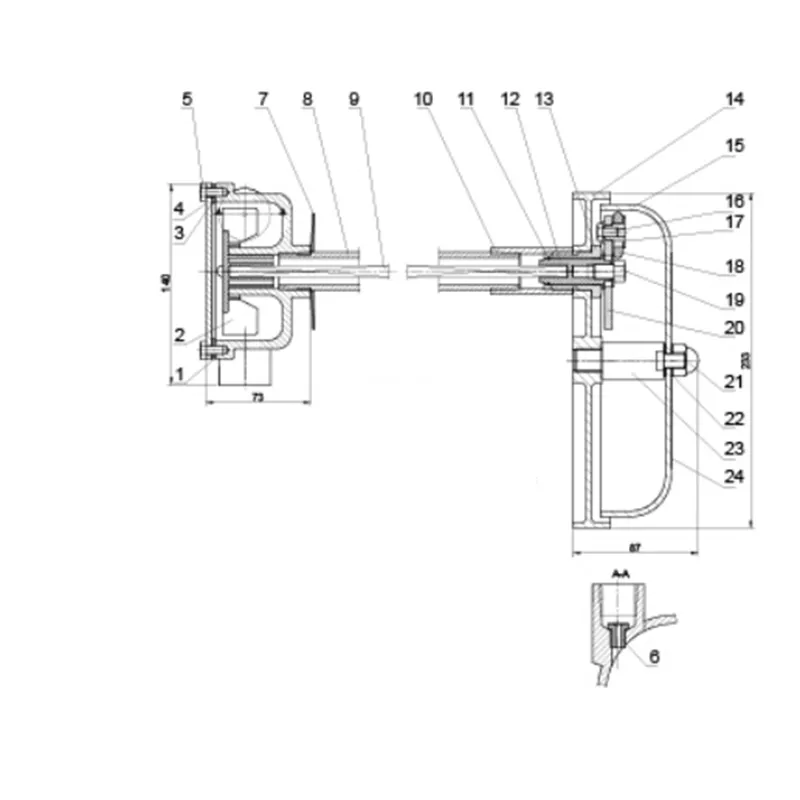

Water Motor Gong Definition and Components

A Water Motor Gong (Hydraulic Alarm Bell) is a purely mechanical audible alarm device used in fire protection systems. It produces a loud, distinctive ringing sound when water flows through it, activated by water pressure from sprinkler system operation. It requires no electricity to function.

Main Components:

①Gong Housing/Casing: The outer shell that contains all internal parts and protects them from the environment. Typically made of corrosion-resistant metal with a drain hole.

②Water Turbine (Impeller or Pelton Wheel): The core driving component. Pressurized water from the alarm line strikes the blades or buckets of this turbine, causing it to spin rapidly.

③Drive Shaft: Connects the turbine to the hammer mechanism, transmitting the rotational force.

④Hammer Assembly: Converts the rotational motion into a striking action. It consists of:

Hammer Head: The weighted part that physically strikes the gong bell.

Eccentric Cam or Trip Mechanism: Attached to the drive shaft, this mechanism lifts and releases the hammer head with each rotation.

⑤Gong Bell: A tuned, resonant metal bell (usually brass or aluminum) that is struck by the hammer to produce the audible alarm signal.

⑥Inlet Connection: The threaded or flanged port where the alarm water line from the alarm valve connects.

⑦Outlet/Drain Connection: The discharge port for water after it has passed through the turbine.

Role, Characteristics, and Application Scenarios of Water Motor Gong in Pipelines

Fire Valves Functions in Pipelines:

- Local Audible Alarm: Provides an unmistakable, loud mechanical ringing at the location of the fire alarm valve (often in a stairwell, riser room, or outside the building) to alert building occupants and responders that the sprinkler system has activated.

- Mechanical Verification: Serves as a direct, non-electrical confirmation that water is actually flowing in the alarm line, verifying the operation of the alarm valve.

- Backup Alarm: Functions independently of electrical power or control panels, providing a fail-safe alarm.

Operational Features:

- Purely Hydraulic/Mechanical: No electrical connections, batteries, or external power required.

- Automatic Activation: Begins ringing as soon as sufficient water flow (typically 2-10 GPM / 8-38 LPM, depending on model) from the alarm valve reaches it.

- Continuous Operation: Rings continuously as long as water flows. Stops only when the water flow stops and the system is reset.

- High Sound Output: Designed to produce a minimum sound level (e.g., 70 dB at 10 ft / 3 m per NFPA standards) to be heard over ambient noise.

Fire Sprinkler Alarm Check Valve Application Scenarios:

- Used in conjunction with Wet, Dry, Preaction, and Deluge Alarm Valves in automatic fire sprinkler systems. It is a mandatory component of the alarm valve assembly.

- Location: Installed on the alarm line of the alarm valve, typically:

- In the fire riser room or sprinkler valve room.

- On an exterior wall where the sound can be heard.

- In a building stairwell.

Diagram: Integration with a Wet Alarm Valve

Water Motor Gong Standards: Materials, Design, and Connections

Design & Performance Standards:

- GB 5135.2-2019 (China): Specifies requirements for Water Motor Gongs as part of the alarm valve assembly (flow rates, sound levels).

- UL 753 (USA): Standard for Alarm Accessories for Automatic Water Supply Control Valves.

- NFPA 13 (USA): Standard for the Installation of Sprinkler Systems, references their installation and performance.

- EN 12259-1 (Europe): Fixed firefighting systems - Components for sprinkler and water spray systems.

Material Standards:

- Housing/Casing: Corrosion-resistant materials like bronze (C84400), brass, coated ductile iron, or stainless steel (e.g., SS304).

- Internal Mechanism (Turbine, Shaft, Hammer): Stainless steel, brass, or bronze for corrosion resistance and durability.

- Gong Bell: Brass or aluminum alloy for optimal sound resonance and corrosion resistance.

- Fasteners: Stainless steel.

Connection Standards:

- Threaded Connections: Most common. Standard sizes are 3/4" NPT (National Pipe Tapered) or 1" NPT (USA/International) or G3/4" / G1" (BSPT - Europe/Asia).

- Flanged Connections: Used for some specific or high-capacity models.

- The inlet/outlet sizes and threads must match the alarm line piping specified in the system design.

How to Select Water Motor Gong

Define Specifications:

- Connection Type & Size: (e.g., 3/4" NPT female inlet).

- Operating Pressure Range: Must be compatible with your system's alarm line pressure.

- Required Minimum Flow Rate: The GPM/LPM needed to start and sustain operation (per system design or standard).

- Sound Level Requirement: Minimum dB rating at a specified distance.

- Material Preference: Bronze, coated iron, etc.

- Certification: Required for the target market (CCCF for China, UL for USA/Canada, CE for Europe).

Source Suppliers:

- Fire Protection System Manufacturers: Often sell components separately (Tyco/Viking, Victaulic, Reliable, etc.).

- Specialized Component Suppliers: Companies that manufacture or distribute specific alarm devices.

- Check for Certification: Ensure the product model is listed/certified under the relevant standard (UL Listed, CCCF certified).

Procurement Process:

- Request datasheets and certification documentation.

- Provide a sample system diagram to ensure compatibility.

- Request a sample for testing if ordering in large volume.

- Clarify packaging, lead time, and Incoterms (FOB, CIF, etc.).

Pre-Shipment Inspection for Export Water Motor Gongand Key Considerations

Inspection Checklist:

- Visual & Dimensional Inspection:

- Check for defects in casting, machining, or plating/coating.

- Verify material markings on the housing/bell.

- Use thread gauges to verify inlet/outlet thread size and quality.

- Ensure the hammer moves freely and the bell is securely mounted.

Functional Test (If Possible):

- Connect to a test water supply.

- Apply water flow at the specified minimum rate. The gong should start ringing within seconds.

- Measure the sound level at a specified distance (e.g., 3 meters) using a sound level meter to verify it meets the datasheet claim.

- Observe that water drains freely from the outlet.

Documentation & Marking Check:

- Verify permanent markings: Manufacturer's name/model, inlet size, directional arrow (if any).

- Check for certification marks (UL logo, CCCF "S" label serial number).

- Review the packing list and ensure all documents (certificate of conformity, test report) are included.

Packaging Inspection:

- Each gong should be individually packaged in a plastic bag or bubble wrap with desiccant to prevent moisture/rust during transit.

- It should be securely placed in a sturdy carton or crate to prevent movement.

- The carton should be clearly marked with the model, quantity, and "Fragile" warnings.

Key Precautions for Export:

- Anti-Corrosion: After any functional wet testing, units must be COMPLETELY DRIED INTERNALLY using compressed air. Residual water will cause corrosion and freezing damage during shipping.

- Certification Compliance: Ensure the product has the correct certification marks for the destination country. Non-compliant products can be rejected at customs.

- Spare Parts/Components: Consider purchasing spare gong bells or hammer kits if the installation environment is harsh (e.g., coastal areas with salt air).

Water Motor Gong Material List

.png)

.png)