Air Releasing Valve NPT Threaded Type

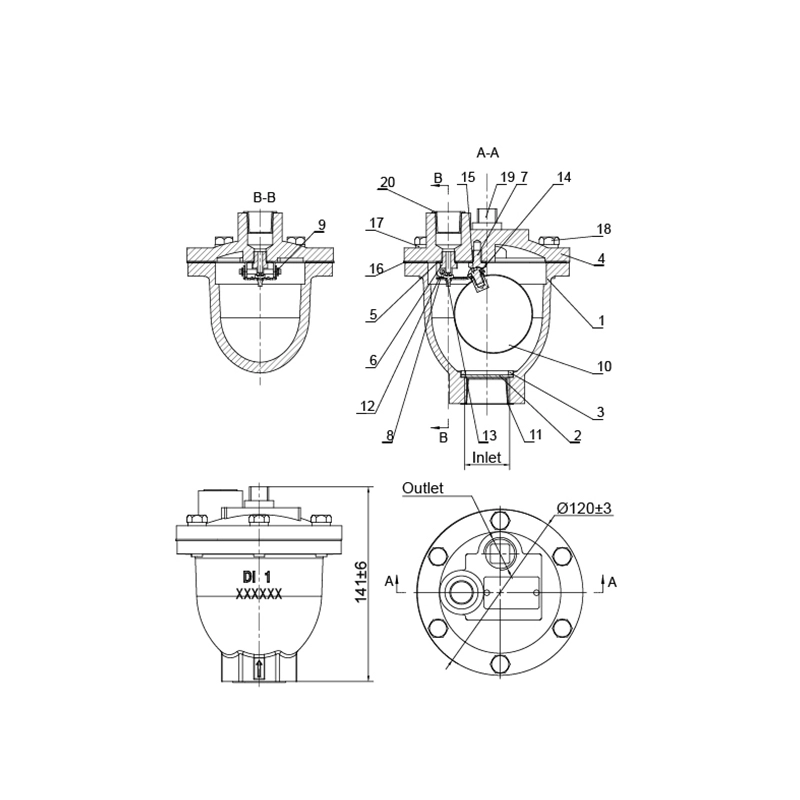

Air Releasing Valve NPT Threaded Type Definition and Components

What is an Air Releasing Valve NPT Threaded Type?

An Air Releasing Valve (ARV), specifically the NPT Threaded Type, is an automatic valve designed to continuously vent small pockets of accumulated air or gas from a liquid-filled pipeline system during normal operation. It features National Pipe Tapered (NPT) threads for connection, making it suitable for smaller pipe sizes and easier installation without welding or flanging.

Air Release Valve Fire Sprinkler Main Parts:

①Valve Body: Main housing containing internal mechanisms, with NPT threaded ports.

②Float Assembly: The core sensing element.

Float: A hollow, sealed ball or cylinder (typically stainless steel or plastic) that rises and falls with the liquid level inside the valve chamber.

③Float Arm/Lever: Connects the float to the pin/seat mechanism.

Lever/Pin Mechanism: Transmits float movement to the seal.

④Seat & Seal (Orifice Seal): A small orifice and its sealing element (elastomer or metal) that opens and closes to release air.

⑤Protective Cap: Screws onto the body, covering the mechanism. Often includes a small vent hole and protects against dirt while allowing air to escape.

Role, Characteristics, and Application Scenarios of Air Releasing Valve NPT Threaded Type in Pipelines

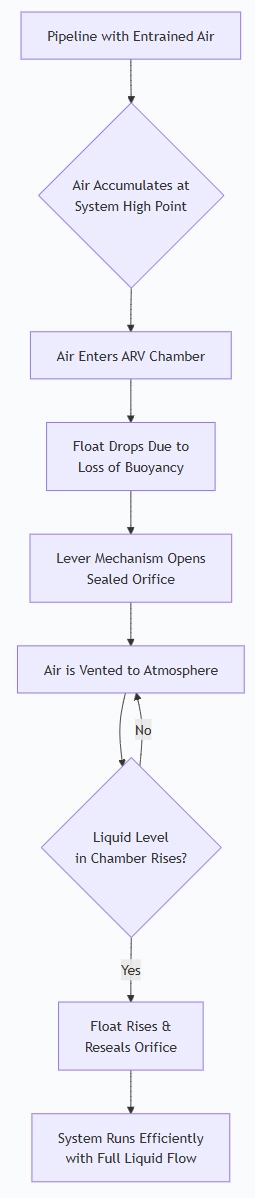

Fire Valves Functions in Pipelines:

- Continuous Micro-Venting: Automatically releases small, trapped air pockets that accumulate at system high points during operation.

- Maintain System Efficiency: Prevents airlocks, reduces turbulence and corrosion (caused by entrained air), and ensures full pipe cross-section for optimal flow and pump efficiency.

- Protect System Components: Helps prevent cavitation in pumps and water hammer caused by compressed air pockets.

Operational Features:

- Automatic Operation: Opens when air enters the valve chamber (causing the float to drop) and closes when liquid returns (causing the float to rise and seal the orifice).

- Small-Orifice Design: Designed for continuous release of small air volumes, not for large air volumes during filling or draining.

- NPT Threaded Connection: Easy installation into threaded tees or couplings at pipeline high points.

Application Scenarios:

- Installed at local high points in pressurized liquid piping systems.

- Water Supply & Distribution Mains

- HVAC Chilled/Heating Water Circuits

- Industrial Process Lines (chemical, food & beverage)

- Fire Sprinkler System Riser Heads

- Irrigation Systems

Operational Scenario Diagram:

Air Releasing Valve NPT Threaded Type Standards: Materials, Design, and Connections

Air Release Valve for Fire Sprinkler System Material Standards:

- Body/Bonnet: Bronze (C84400/C83600) most common, Ductile Iron (ASTM A536) for larger sizes, Stainless Steel (ASTM A351 CF8/CF8M) for corrosive fluids.

- Float: Stainless Steel (AISI 304/316) or Polypropylene/PTFE for chemical resistance.

- Seals: Nitrile (NBR), EPDM, Viton (FKM) per fluid compatibility. PTFE for aggressive chemicals.

- Spring: Stainless Steel (302/316).

Design & Performance Standards:

- AWWA C512: "Air Release, Air/Vacuum, and Combination Air Valves for Water and Wastewater Service" (primary US standard).

- ISO 12149: "Automatic air vents for heating systems."

- EN 1074-4: "Valves for water supply - Fitness for purpose requirements and appropriate verification tests - Air valves."

- ASME B16.34: Valves - Flanged, Threaded, and Welding End.

- Factory Mutual (FM) / UL approvals for fire protection applications.

Connection Standard:

- NPT (National Pipe Tapered): ANSI/ASME B1.20.1.

- Common Sizes: 1/2" NPT, 3/4" NPT, 1" NPT. The connection is always female threaded (FPT) on the valve body to screw onto a male-threaded (MPT) pipeline tee or nipple.

How to Select Air Releasing Valve NPT Threaded Type

Steps for Purchasing:

① Define Specifications:

Fluid: Water, oil, chemical, etc. (determines material choice).

Operating Pressure & Temperature Range: Must match or exceed system max.

Pipe Size: Determines NPT thread size (e.g., for a 4" main, a 1" NPT tapped tee with a 1" ARV is typical).

Material Grade: Bronze for standard water, SS316 for seawater/corrosive fluids.

Seal Material: EPDM for hot water, NBR for oils, Viton/FKM for high temps/chemicals.

Certifications: AWWA, FM/UL, CE/PED, specific client standards.

② Source Suppliers:

Specialized Valve Manufacturers: (e.g., APCO, Val-Matic, BERMAD, DeZURIK).

Industrial/MRO Distributors: (e.g., Ferguson, Grainger).

B2B Platforms: (e.g., Alibaba for OEM sourcing). Verify certifications.

③ Request & Evaluate Quotations:

Request technical datasheets, material certifications (e.g., CMTR), and certification copies.

Compare key parameters: pressure rating, orifice size, materials of construction.

Clarify packaging, minimum order quantity (MOQ), lead time, and Incoterms.

Pre-Shipment Inspection for Export Air Releasing Valve NPT Threaded Type and Key Considerations

Inspection Checklist:

| Area | Checkpoint | Method/Tool |

| Visual & Dimensional | Body casting defects (cracks, pores) | Visual inspection |

| Correct markings (Size, Pressure, Material, Brand) | Visual inspection | |

| NPT thread quality, cleanliness, damage | Thread gauge, visual | |

| Free movement of float mechanism (shake test) | Manual | |

| Material Verification | Body material vs. spec (e.g., bronze) | Check Mill Test Report (MTR) |

| Seal material vs. spec (e.g., EPDM) | Check supplier documentation | |

| Functional Test | Dry Air Test: Immerse valve in water, apply low-pressure air to inlet. No bubbles should escape from cap vent. |

Air compressor, water tank |

| Float Mechanism Test: Manually hold float down, blow air through inlet; air should exit vent. Release float; airflow should stop. |

Manual, compressed air | |

| Documentation | Packing List accuracy (Qty, Model) | Document check |

| Certificates (MTR, Certificate of Conformance) | Document check | |

| Packaging | Individual protection (plastic bag + desiccant) | Visual inspection |

| Secure boxing to prevent damage | Visual inspection | |

| Export carton marking (Fragile, Keep Dry) | Visual inspection |

Air Releasing Valve NPT Threaded Type Material List

| S/N | Description of Parts | Materials |

| 1 | Valve Body | Ductile Iron |

| 2 | Filter Screen | SS316 |

| 3 | Gasket Ring | Carbon Steel |

| 4 | Bonnet | Ductile Iron |

| 5 | Yoke | SS316 |

| 6 | Valve Seat | SS316 |

| 7 | Bolt | SS316 |

| 8 | Valve Shaft | SS316 |

| 9 | E Type Retainer Ring | SS304 |

| 10 | Ball | SS316 |

| 11 | Large Protective Cover | Plastic |

| 12 | Lever | SS316 |

| 13 | Poppet | EPDM |

| 14 | Spring Washer | SS316 |

| 15 | Hex Socket Head Bolt | SS304 |

| 16 | Asbestos-free Gasket | CN-705 |

| 17 | Spring Washer | Carbon Steel |

| 18 | Bolt | Carbon Steel |

| 19 | Plug | Ductile Iron |

| 20 | Small Protective Cover | Plastic |

.png)

.png)