Twin Sphere Flanged Flexible Rubber Joint KDTF 1

Twin Sphere Flanged Flexible Rubber Joint Definition and Components

What is a Twin Sphere Flanged Flexible Rubber Joint KDTF 1 and its main parts?

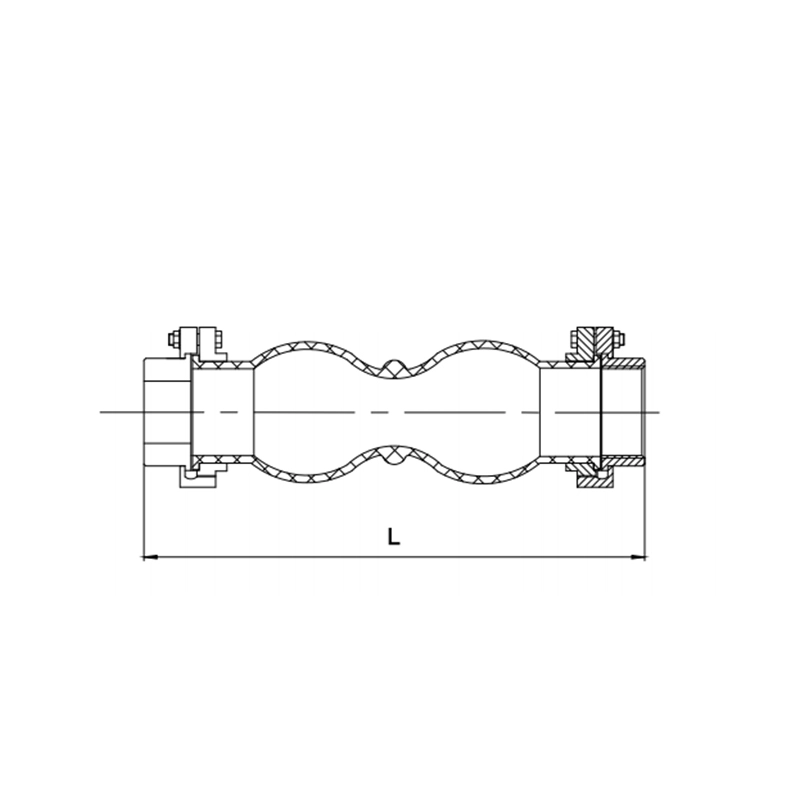

A Twin Sphere Flanged Flexible Rubber Joint KDTF 1 is a highly flexible piping component designed to absorb significant movement and vibration. It consists of two spherical rubber bodies connected by a central section, with integral flanges at each end for bolted connection. The "twin sphere" design provides greater axial compression/extension, lateral offset, and angular deflection than single-arch joints.

Flexible Rubber Joint Flange Main Parts:

- Twin Rubber Spheres (Arch): The primary flexible element, made of elastomer (e.g., natural rubber, EPDM). The two spherical convolutions provide the flexibility.

- Reinforcement Layer: Multiple plies of high-tensile fabric (like nylon or polyester) or steel cord embedded within the rubber to provide pressure rating and dimensional stability.

- Flanges: Integral, molded steel flanges (typically carbon steel with anti-corrosive coating) at each end for bolting to pipeline flanges.

- Inner Liner: A smooth, continuous layer of rubber inside the joint to ensure fluid compatibility and minimize turbulence/erosion.

- External Cover: A weather- and ozone-resistant rubber layer protecting the reinforcement.

Role, Characteristics, and Application Scenarios of Twin Sphere Flanged Flexible Rubber Joint in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Primarily to absorb multi-directional movement (axial, lateral, angular), dampen vibration and noise, compensate for minor pipeline misalignment, and relieve pipe stress.

Operational Features:

- High Flexibility: The dual-sphere design offers superior movement capacity in all directions compared to single-arch joints.

- Pressure Containment: Reinforcement layers allow it to handle system pressure while flexing.

- Non-Conductive: Electrically isolates different pipe sections, preventing galvanic corrosion.

- Minimal Maintenance: No moving parts; maintenance-free under normal conditions.

- Usage Scenarios: Used in piping systems subject to movement, vibration, or thermal expansion/contraction

- Water & Wastewater Plants: Pump inlet/outlet to absorb vibration and movement.

- HVAC Systems: On chillers, cooling towers, and pumps.

- Industrial Process Piping: Connecting to vibrating machinery (compressors, generators).

- Marine & Shipbuilding: For engine exhaust lines, seawater systems.

- District Heating/Cooling: To accommodate thermal expansion in long pipe runs.

Twin Sphere Flanged Flexible Rubber Joint Standards: Materials, Design, and Connection

Material, Design, and Connection Standards

Water Valves Material Standards:

- Elastomer: Commonly EPDM (for hot water, steam, weathering), NBR (for oils, fuels), Natural Rubber (for general water, low temp).

- Reinforcement: High-tensile synthetic cord or steel wire, per manufacturer's specification.

- Flanges: Carbon steel (e.g., ASTM A36) with rubber covering or protective coating (e.g., galvanized, epoxy).

- Design & Performance Standards: Widely follows AWWA C219 (for waterworks service) or general industry standards like ISO 9001 for manufacturing quality. Performance criteria (pressure, movement) are typically per manufacturer's catalog based on design.

- Connection Standards: The flanges conform to common piping flange standards:

- ASME B16.5 (Class 125/150, Raised Face common)

- EN 1092-1 (DIN) (PN6/PN10/PN16)

Flange drilling and dimensions match the specified standard.

How to Select Twin Sphere Flanged Flexible Rubber Joint

How to Purchase

- Specify Parameters: Determine key requirements: nominal size (DN/NPS), operating pressure and temperature, media being conveyed, required movement capacities (axial compression/extension, lateral, angular), and preferred elastomer type based on media and environment.

- Identify Suppliers: Source from reputable manufacturers specializing in rubber expansion joints. Verify quality control systems and project references.

- Request Technical Quotation: Provide the above parameters. Request a detailed technical datasheet specifying all materials, reinforcement plies, pressure/movement ratings, and flange standards. Ask for dimensional drawings.

- Evaluate & Order: Compare technical suitability, price, lead time, and warranty. Ensure the purchase order explicitly lists size, pressure rating, elastomer type, flange standard, and any special requirements (e.g., conductive rubber, FDA-approved materials).

Pre-Shipment Inspection for Export Twin Sphere Flanged Flexible Rubber Joint and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Inspect for surface defects, bonding integrity between rubber and flanges. Verify overall length, flange diameter, and bolt hole alignment per drawing.

- Material Verification: Check provided certificates for rubber compound and flange material.

- Marking Verification: Ensure permanent marking includes size, pressure rating, manufacturer, and elastomer type.

- Packaging Inspection: Each joint should be individually packaged to prevent deformation, twisting, or flange damage. Wooden crates are typical for large sizes.

Flexible Rubber Joint Precautions:

- Prevent Distortion: Store and ship joints in a neutral, relaxed position. Do not stack heavy items on them.

- Protect Flanges: Use protective caps/boards on flange faces to prevent bolt hole damage and corrosion.

- Environmental Protection: Protect from ozone, UV, and extreme temperatures during storage/transit.

- Documentation: Ensure packing list, material certificates, and installation manuals are enclosed. Exterior crates must be clearly marked with handling instructions ("Do Not Crush," "Keep Dry") and identification info.

Twin Sphere Flanged Flexible Rubber Joint Main dimensions(mm)

| DN | L(mm) | |

| Inches | mm | |

| 1/2’ | 15 | 170 |

| 3/4’ | 20 | 170 |

| 1 1/4’ | 25 | 170 |

| 1 1/2’ | 32 | 185 |

| 1’ | 40 | 185 |

| 2’ | 50 | 185 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)