Lugged Type Wafer Butterfly Valve Model LTD71X

Lugged Type Wafer Butterfly Valve Model LTD71X Purpose

This Lugged Wafer Butterfly Valve is used as a cutoff and adjusting equipment for the various water supply and drainage pipelines in building chemical, medicine, textile, ship and other industries.

Lugged Type Wafer Butterfly Valve Model LTD71X Definition and Components

A Lugged Type Wafer Butterfly Valve Model LTD71X is a quarter-turn isolation valve that combines the space-saving profile of a wafer valve with the installation versatility of a lugged design. Unlike a standard wafer valve, it features integrated threaded lugs (ears) on the valve body. These lugs allow the valve to be bolted directly to a single flange, making it suitable for end-of-line service or easy removal without dismantling the entire pipeline.

Model Code Breakdown:

- L: Lugged Body Type

- T: Often denotes a Triple Offset or high-performance design, but in simpler models, it may indicate a standard concentric disc. In this context, we'll assume a standard resilient-seated design.

- D71: Butterfly Valve series with a specific design profile.

- X: Indicates an EPDM (Ethylene Propylene Diene Monomer) resilient seat.

Main Parts:

- Lugged Body: Ductile Iron or Stainless Steel body with threaded inserts or cast lugs protruding from the sides.

- Disc: Concentric or slightly offset disc (Ductile Iron or SS) that seals against the seat.

- Resilient Seat (EPDM): An elastomer ring bonded or fitted into the body for bubble-tight shut-off.

- Stem: Stainless steel shaft connecting the disc to the actuator.

- Stem Seals: O-rings or packing to prevent leakage along the stem.

- Lever Handle: Standard quarter-turn manual actuator.

- Threaded Lugs: Typically have through-holes with threads to accept flange bolts.

Role, Characteristics, and Application Scenarios of Lugged Type Wafer Butterfly Valve Model LTD71X in Pipelines

Butterfly Valve for Water Functions in Pipelines:

- End-of-Line (Dead-End) Isolation: Can be bolted to a single flange to blank off a pipe end or isolate a branch line, supporting the weight of the downstream pipe.

- Easy Maintenance Removal: Allows one side of the pipeline to be disconnected for valve maintenance or replacement without requiring the opposing flange to be unbolted.

- Bidirectional Isolation: Provides reliable shut-off for flow in either direction.

- Space-Constrained Mounting: Offers more mounting flexibility than a wafer valve in tight spaces.

Water Valves Operational Features:

- Lugged Design Versatility: Can be installed as a spool piece (like a wafer valve) using longer bolts through both flanges, OR installed using two separate bolt sets threaded into the lugs.

- Quarter-Turn Operation: Fast open/close with a lever handle.

- Resilient Seat: EPDM provides excellent sealing for water and many mild chemicals at moderate temperatures.

- Pressure Rating: Typically PN10/16 (Class 125/150).

Common Usage Scenarios:

- Pump Suction/Discharge: For easy isolation and removal of pumps.

- Equipment Isolation: For heat exchangers, tanks, or filters where one side may need frequent disconnection.

- Branch Line Isolation: At the take-off point from a main header.

- HVAC Systems: In chilled water loops for component isolation.

- Water Treatment Plants: For isolating valves, meters, or other inline equipment.

Lugged Type Wafer Butterfly Valve Model LTD71X Standards: Materials, Design, and Connections

Material Standards:

- Body: Ductile Iron (ASTM A536) with epoxy coating (standard). Stainless Steel (ASTM A351 CF8/CF8M) for corrosive service.

- Disc: Ductile Iron with Ni-plating or Stainless Steel.

- Stem: Stainless Steel (AISI 304, 316, or 17-4PH).

- Seat: EPDM per ASTM D2000. Alternative seats: NBR, Viton.

- Lugs: Integral to the body casting, with threaded steel inserts for bolt engagement.

Design & Performance Standards:

- API 609: Covers design and testing of lug-style butterfly valves.

- ISO 5752: Basic series face-to-face dimensions.

- MSS SP-67: Standard for "Butterfly Valves."

- Pressure Rating: Standard is Class 125 or Class 150. Must be verified for dead-end pressure rating, which is typically lower than the full pressure rating.

Connection Standards:

- Lug Design: Threaded lug holes are sized for standard flange bolts (e.g., for ANSI Class 150 flanges).

- Flange Compatibility: Designed to fit between ANSI B16.1 (Cast Iron) or B16.5 (Steel) flanges.

- Face-to-Face: Dimensions conform to API 609 or ISO 5752 short series.

How to Select Lugged Type Wafer Butterfly Valve Model LTD71X

Purchasing Guide:

Define Application & Critical Specifications:

- Service: Water, air, other media? Confirm EPDM seat compatibility.

- Installation Type: Will it be used as a dead-end valve or a standard spool? This affects the required pressure rating.

- Size & Pressure Class: Nominal diameter (e.g., 8") and required ANSI Class (e.g., 150).

- Material: Standard is epoxy-coated ductile iron. Upgrade to stainless steel if needed.

- Actuator: Confirm lever handle is sufficient, or specify a gear operator for larger sizes/higher torque.

Specify Technical & Quality Requirements:

- Dead-End Pressure Rating: Explicitly request the manufacturer's certified dead-end service pressure rating for the valve.

- Lug Thread Specification: Specify thread type (e.g., UNC) and ensure lugs are suitable for the bolt grade used in your flanges.

- Standards Compliance: Specify conformance to API 609.

Testing & Certification: Require a factory test certificate per API 598, including a seat leakage test. Request material documentation.

Supplier Evaluation & Sourcing:

Source from established industrial valve manufacturers.

Provide clear specifications, emphasizing the lugged design requirement. Request dimensional drawings for approval.

Compare offerings, prioritizing those that provide clear dead-end service ratings and full certification.

Pre-Shipment Inspection for Export Lugged Type Wafer Butterfly Valve Model LTD71X and Key Considerations

Inspection Procedure:

Visual & Dimensional Inspection:

Check body coating and lug integrity. No cracks or porosity in castings.

Verify all lug holes are clean, threaded, and undamaged. Test with a bolt.

Measure face-to-face and overall dimensions against the approved drawing.Operate the lever; disc should rotate smoothly without contacting the seat except in the closed position.

Review of Mandatory Documentation:

- Factory Test Certificate (API 598): Confirm successful shell and seat tests.

- Pressure Rating Documentation: Verify the documentation clearly states both the full pressure rating and the dead-end service pressure rating.

- Material Certificates: For body and disc.

Packaging Inspection:

Valve must be clean and dry. The disc should be in the partially open position.

Critical: All lug threads must be protected with threaded plastic plugs or caps to prevent damage during shipping.

Sealing faces must be protected by cardboard or plastic covers.

Lugged Type Wafer Butterfly Valve Model LTD71X Main part materials

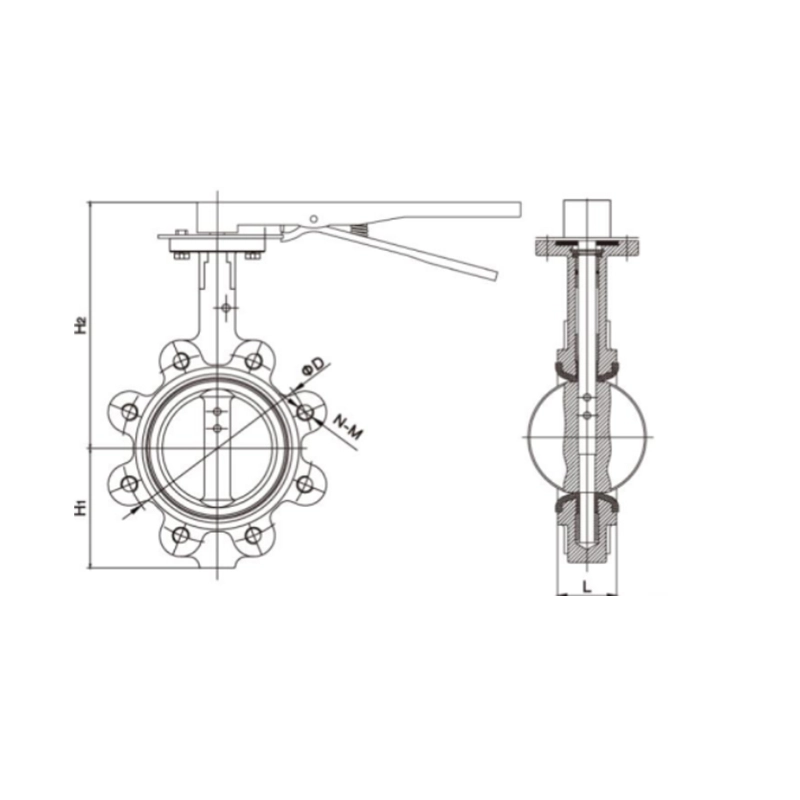

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 43 | 46 | 46 | 52 | 56 | 56 | 60 | 68 | 74 |

| D | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 |

| N-M | 4-M16 | 4-M16 | 8-M16 | 8-M16 | 8-M16 | 8-M20 | 12-M20 | 12-M24 | 12-M24 |

| H1 | 70 | 76 | 97 | 114 | 126 | 141 | 170 | 204 | 232 |

| H2 | 173 | 180 | 188 | 208 | 224 | 239 | 272 | 331 | 369 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)