Why Grooved End Wet Alarm Valves Offer Significant Advantages for End-of-Line Connections

December 18, 2025

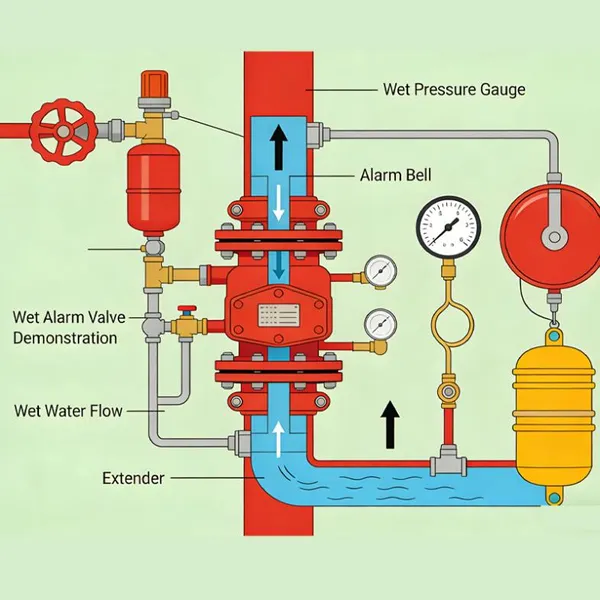

In modern fire protection systems, reliability, installation efficiency, and long-term performance are critical. Among all system components, the wet alarm check valve plays a central role. It controls water flow, triggers alarms, and ensures rapid response when a fire occurs.

As fire system designs evolve, more contractors and engineers are choosing grooved end wet alarm valves, especially for end-of-line connections. Compared with traditional flanged or threaded designs, grooved end connections deliver clear advantages in installation speed, flexibility, and system reliability.

This article explains why grooved end wet alarm valves are increasingly preferred and how they add value to fire protection projects.

Understanding Grooved End Wet Alarm Valves

A wet alarm valve is designed for systems that remain filled with water at all times. When a sprinkler activates, water flows through the valve and triggers an alarm device, providing immediate fire notification.

What Makes a Grooved End Design Different

Grooved end wet alarm valves use mechanical grooved couplings instead of flanges or threads. This connection method relies on:

- Precision-machined grooves

- Flexible couplings and gasket

- Simple bolt tightening

For end-of-line installations, where space and access can be limited, this design offers major practical benefits.

| project | ZSFZ100 4″ | ZSFZ150 6′ |

| nominal diameter | 100 | 150 |

| nominal working pressure | 1.2 to 1.6 MPa | 1.2~1.6MPA |

| valve body strength test pressure | 4.8 to 6.4 MPa | 4.8-6.4Mpa |

| valve sealing test pressure | 2.4 to 3.2 MPa | 2.4-3.2Mpa |

| Numbering and Diameter of Flange Bolt Holes | 8 by 18 | 8*22 |

| alarm valve high | 565 millimeters | 675 millimeters |

| flange outer diameter | 220 millimeters | 285 millimeters |

| French screw hole diameter | 180 millimeters | 240 millimeters |

| rub | less than 0.07 MPa | below 0.07Mpa |

| start time | less than 15 seconds | Under 15 seconds |

Faster and More Efficient Installation at End-of-Line Locations

Installation time directly affects project cost and schedule. Grooved end connections significantly simplify this process.

Reduced Labor and Assembly Time

Compared with flanged connections, grooved end wet alarm valves:

- Eliminate flange alignment issue

- Do not require gasket positioning between flanges

- Avoid time-consuming bolt torque sequences

Installers can complete connections quickly with basic tools. This advantage becomes more visible at end-of-line locations, where working space is often restricted.

No On-Site Welding or Threading

Grooved systems avoid hot work and thread cutting on site. This improves job-site safety and reduces installation errors. For retrofit projects or system extensions, this benefit is especially valuable.

Reliable Sealing Performance for Fire Protection Systems

Leak prevention is essential in fire systems. Even small leaks can reduce pressure and compromise performance.

Consistent Sealing Under Pressure

Grooved couplings use elastomeric gaskets that provide:

- Uniform compression around the pipe

- Stable sealing under pressure fluctuations

- Reliable performance during long standby periods

This sealing method performs well in wet systems that remain pressurized for extended time.

Reduced Risk of Installation Errors

Flanged connections rely heavily on bolt torque balance. Uneven tightening often causes leaks. Grooved connections simplify the process and reduce human error, improving overall system quality.

Space-Saving Design for Compact End-of-Line Areas

End-of-line installations often face space limitations due to building structure or existing pipelines.

Grooved end wet alarm valves typically feature:

- Shorter face-to-face dimensions

- Compact body profiles

- Fewer external components

These features allow easier installation in confined areas and improve layout flexibility.

Lower Maintenance and Lifecycle Costs

Maintenance efficiency matters throughout the system’s service life.

Simplified Inspection and Replacement

Grooved connections allow faster disassembly. Maintenance teams can:

- Remove the valve without disturbing adjacent piping

- Reduce system downtime

- Complete inspections more efficiently

This advantage is particularly useful in commercial buildings and industrial facilities where downtime must remain minimal.

Long-Term Cost Efficiency

Although initial product cost may be similar, grooved end wet alarm valves often reduce:

- Installation labor cost

- Maintenance time

- Risk of leakage-related repairs

Over the system lifecycle, these savings become significant.

Why Choose Fuid Tech Group Grooved End Wet Alarm Valves

As a professional fire protection valve and pipe fitting supplier, Fuid Tech Group focuses on performance, reliability, and installation practicality.

Our grooved end wet alarm valves offer:

- Durable valve bodies designed for fire systems

- Precision grooved ends for secure connections

- Compatibility with standard grooved coupling systems

- Stable alarm response and flow performance

All products follow strict quality control procedures and meet applicable fire protection standards.

Conclusion: A Practical Choice for Modern Fire Systems

For end-of-line connections, grooved end wet alarm valves offer significant advantages. They improve installation efficiency, increase system flexibility, reduce leakage risk, and simplify maintenance.

As fire protection systems continue to evolve, grooved end designs represent a practical and proven solution for modern projects.

If you are planning a new installation or upgrading an existing system, Fuid Tech Group is ready to support you with reliable grooved end wet alarm valve solutions and professional technical assistance.

Contact our team or explore our fire sprinkler alarm check valve range to find the right solution for your fire protection system.

.png)

.png)