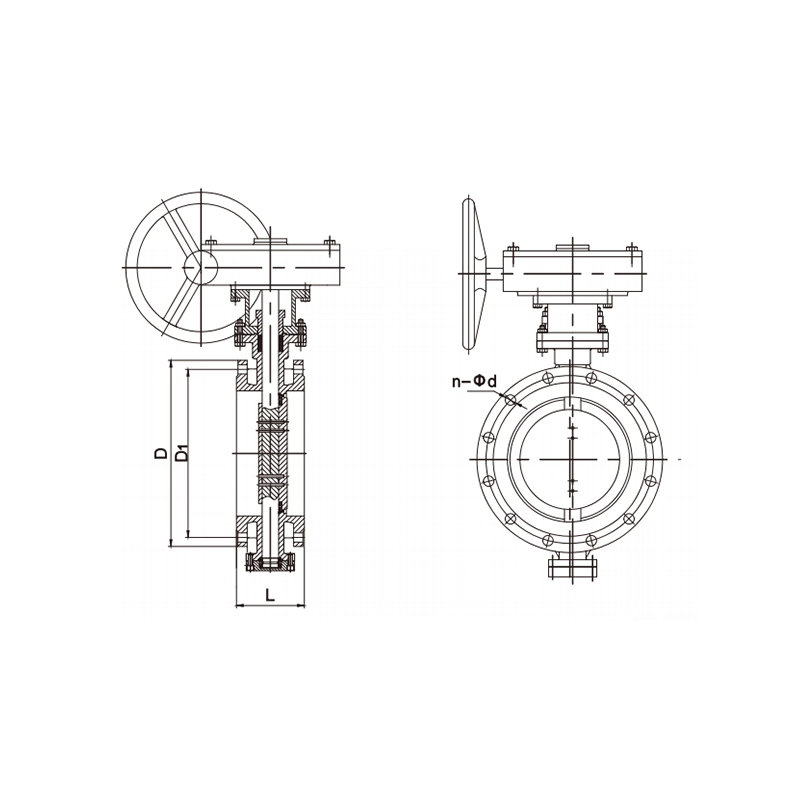

Resilient Seat Flanged Butterfly Valve

Resilient Seat Flanged Butterfly Valve Purpose

The butterfly valve is suitable for use in metallurgy, chemical power, municipal engineering and medium such as water, oil and air pipeline, as cutting fluid and adjust medium flow rate, etc.

Resilient Seat Flanged Butterfly Valve Definition and Components

D342X: Double/Triple Eccentric Flanged Butterfly Valve

- D: Butterfly Valve

- 3: Driving mode - Manual (Gear operated)

- 4: Connection type - Flanged

- 2: Double offset (First two eccentricities)

- X: Resilient Seat (Rubber or polymer sealing)

D343X: Triple Eccentric Flanged Butterfly Valve

- 3: Triple offset (All three eccentricities)

- X: Resilient Seat (Often with fire-safe capability)

Eccentricity Explained:

Standard (D341X): 0° Offset - Disc rotates around center

Double Eccentric (D342X):

1.Stem offset from centerline (First offset)

2.Stem offset from seat centerline (Second offset)

→ Reduces seat wear, easier operation

Triple Eccentric (D343X):

1.Stem offset from centerline

2.Stem offset from seat centerline

3.Seat cone angle offset (Third offset - conical seat)

→ Zero friction, bubble-tight, bidirectional sealing

Main Components:

| Component | Material/Description | Function |

| 1. Valve Body | Cast Steel (WCB/WCC), Ductile Iron, Stainless Steel (CF8/CF8M) | Pressure-retaining structure with flanges |

| 2. Disc | Same as body + coating (Ni-plated, epoxy, STL overlay) | Offset rotating element with eccentric design |

| 3. Stem | Forged SS 410/304/316/17-4PH | Double/triple offset shaft connecting operator to disc |

| 4. Resilient Seat | Laminated/Rubber-Metal: | Provides bubble-tight seal, compensates for thermal expansion |

| • Primary: PTFE/RTFE, Reinforced Graphite | ||

| • Secondary: Metal seat backing | ||

| • Fire-safe: Graphite filler | ||

| 5. Bearing System | Bronze/SS/PTFE composite bushings | Supports stem, reduces friction at offset points |

| 6. Seals & Gaskets | • Stem seals: Chevron/V-ring/Spring-energized | Prevent leakage at stem and body joints |

| • Body seal: Spiral-wound gasket | ||

| 7. Gear Operator | Worm gear with position indicator | Provides mechanical advantage for high-torque applications |

Role, Characteristics, and Application Scenarios of Resilient Seat Flanged Butterfly Valve in Pipelines

Fire protection water supply Pipeline Functions:

Primary Roles:

1.Bidirectional Isolation- Zero leakage shut-off in both directions

2.High-Pressure/Temp Regulation- Throttling in severe service

3.Fire-Safe Protection- Secondary metal-to-metal sealing during fire

4.Cavitation/Noise Reduction- Offset design minimizes turbulence

5.Long-term Reliability- Minimal wear due to no-rubbing design

Butterfly Valve for Water Operational Features Comparison:

| Feature | D342X (Double Eccentric) | D343X (Triple Eccentric) |

| Seat Contact | Minimal contact at closure | Zero contact until closure |

| Torque Requirement | Lower than concentric | Lowest (frictionless) |

| Sealing Capability | Bubble-tight (soft seat) | Bubble-tight + fire-safe |

| Pressure Rating | Up to Class 300 | Up to Class 1500 |

| Temperature Range | -29°C to +200°C | -196°C to +815°C |

| Throttling Capability | Good | Excellent (linear characteristic) |

| Cycle Life | 10,000+ cycles | 100,000+ cycles |

Resilient Seat Flanged Butterfly Valve Standards: Materials, Design, and Connections

Material Standards:

| Component | Standards |

| Body & Disc | • ASTM A216 WCB/WCC (CS) |

| • ASTM A351 CF8/CF8M (SS) | |

| • ASTM A995 4A/5A (Duplex) | |

| • ISO 10893 / EN 10213 | |

| Stem | • ASTM A564 630 (17-4PH) |

| • ASTM A182 F6a/F304/F316 | |

| • NACE MR0175/ISO 15156 | |

| Seat Materials | • Primary: PTFE (ASTM D4894), RPTFE, PEEK |

| • Secondary: 316SS, Inconel | |

| • Fire-safe: Flexible Graphite (ASTM D7542) | |

| Bearings | • ASTM B505 C93200 (Bronze) |

| • PTFE Composite (FDA approved if needed) |

Design Standards:

| Standard | Application | Key Requirements |

| API 609 | Butterfly Valves | Design, testing, fire-safe requirements |

| API 607 | Fire Testing | 30-min fire test for soft-seated valves |

| ISO 17292 | Metal-seated valves | Performance requirements |

| BS EN 593 | Industrial valves | European design standard |

| MSS SP-68 | High-pressure butterfly | Class 150-600 requirements |

| TA-Luft | German emissions | Fugitive emission ≤ 500 ppm |

Connection Standards:

| Flange Standard | Pressure Class | Face Type |

| ASME B16.5 | Class 150-600 | RF, RTJ |

| ASME B16.47 | Class 75-900 | RF, RTJ |

| EN 1092-1 | PN10-PN100 | Type 11, 12, 13 |

| JIS B2220 | 5K-20K | RF |

| ISO 7005-1 | Multiple | Universal |

Face-to-Face Dimensions: ISO 5752 Series 20 (API 609 Table 2)

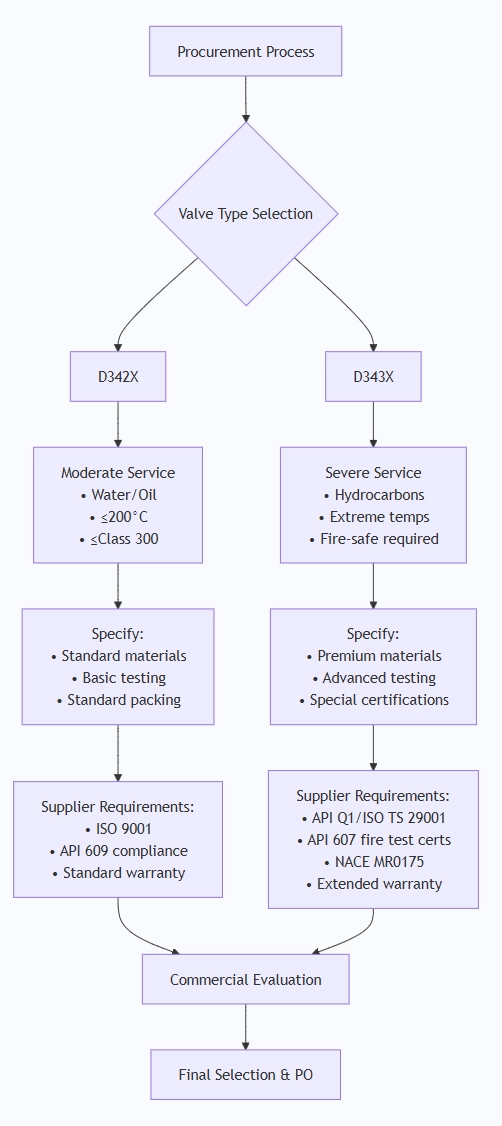

How to Select Resilient Seat Flanged Butterfly Valve

Technical Specification Checklist:

Critical Specifications to Define:

Service Conditions:

- Fluid type (corrosive, abrasive, sanitary)

- Pressure/Temperature profile (min/max/operating)

- Cycle frequency (occasional/continuous)

Design Requirements:

- Pressure class (ANSI/PN)

- Temperature rating (include thermal shocks)

- Fire-safe requirements (API 607/6FA)

- Fugitive emissions (ISO 15848-1/TA-Luft)

- NACE compliance for sour servic

Material Selection Matrix:

- NACE compliance for sour service

Material Selection Matrix:

| Service | Body Material | Seat Material | Stem Material |

| General Water | Ductile Iron | EPDM/PTFE | 304SS |

| Sea Water | Bronze/316SS | PTFE/EPDM | 316SS |

| Oil & Gas | WCB/LCB | RPTFE+Graphite | 17-4PH |

| Cryogenic | LCB/CF8 | PTFE/Graphite | 304/316SS |

| High Temp | WC6/WC9 | Flexible Graphite | 17-4PH/Inconel |

Testing & Certification:

Standard: API 598/ISO 5208

Extended: Shell SPE 77/300 or TOTAL GS EP PVV 142

Third-party inspection required (DNV/BV/SGS)

Fire Protection System Supplier Evaluation Criteria:

| Criteria | Weight | Checklist |

| Technical Capability | 30% | • Design software/FEA |

| • Prototype testing facility | ||

| • Engineering support | ||

| Quality System | 25% | • API Q1/ISO 9001 certified |

| • NDT capabilities | ||

| • Traceability system | ||

| Certifications | 20% | • API 607/6FA fire test |

| • CE/PED/ATEX | ||

| • NACE/ISO 15156 | ||

| Experience | 15% | • Similar project references |

| • Industry recognition | ||

| • Failure rate data | ||

| Commercial | 10% | • Price competitiveness |

| • Delivery reliability | ||

| • Payment terms |

Pre-Shipment Inspection for Export Resilient Seat Flanged Butterfly Valve and Key Considerations

Enhanced Inspection Checklist:

| Inspection Area | D342X Requirements | D343X Additional Requirements |

| Documentation | • Material certs 3.1 | • Fire test certificates |

| • Calibration certs | • NACE compliance certs | |

| • Paint certificates | • Third-party inspection reports | |

| Dimensional | • Face-to-face | • Cone angle measurement |

| • Flange dimensions | • Eccentricity verification | |

| • Drilling template | • Stem offset confirmation | |

| Visual | • Surface finish | • Seat laminate integrity |

| • Marking clarity | • Bearing alignment | |

| • Coating thickness | • Fire-safe features | |

| Functional | • 90° operation | • Friction-free rotation |

| • Position indication | • Zero-contact verification | |

| • No-load torque | • Stem sealing test | |

| Pressure Testing | • Shell test: 1.5×PN | • High-pressure seat test |

| • Seat test: 1.1×PN | • Fire-safe seat test | |

| • Cryogenic test (if applicable) |

Specialized Testing for Eccentric Valves:

Seat Tightness Test (Enhanced):

Test Sequence:

- Low-pressure air test: 0.6 MPa for 1 minute (bubble detection)

- Hydrostatic test: 1.1×PN for 15 minutes

- **High-pressure gas test**: Nitrogen at 80% of yield strength

- **Fire-safe test simulation**: Check secondary metal seat contact

- B. Fire Test Verification (API 607/API 6FA):

Review original fire test certificate (not just compliance)

Verify test was on identical design/size/material

Check test duration and leakage rates:

During fire: ≤ 40 ml/min per inch of seat diameter

After fire: Bubble-tight per API 598

Export Preparation Protocol:

Special Packaging Requirements:

- For D343X valves: VCI (Vapor Corrosion Inhibitor) packaging mandatory

- Desiccant calculation: 50g per m³ of crate volume

- Flange protection: 3mm thick plastic covers bolted (not taped)

- Stem/gear protection: Shrink-wrap with silica gel

Documentation Package:

REQUIRED DOCUMENTS:

├── Commercial Documents

│ ├── Commercial Invoice (3 copies)

│ ├── Packing List (detailed by crate)

│ └── Certificate of Origin

├── Technical Documents

│ ├── Data Book (complete valve record)

│ ├── Material Certificates (EN 10204 3.1/3.2)

│ ├── Test Reports (signed by QC manager)

│ └── Calculation Reports (if applicable)

└── Certification

├── Fire Test Certificates (API 607/6FA)

├── NACE Compliance Certificate

├── CE Declaration of Conformity

└── Third-party Inspection Release Note

Marking & Identification:

- Body marking per MSS SP-25 (minimum requirements)

- Additional markings for eccentric valves:

- Offset direction indicator

- Fire-safe identification (FS logo)

- Torque direction arrows

Color coding: Standard per customer specs or ISO 14726

Critical Inspection Points for Eccentric Design:

Offset Verification:

Measurement Procedure:

- Measure stem center to disc center (First offset)

- Measure stem center to seat center (Second offset)

- For D343X: Verify conical angle (Third offset)

- Tolerance: ±0.1mm for offsets ≤ 50mm

±0.2mm for offsets > 50mm

Seat Installation Check:

- Resilient seat must be uniformly compressed

- No visible gaps between laminations

- Fire-safe graphite rings properly positioned

- Secondary metal seat concentricity within 0.05mm

Bearing Clearance Check:

- Radial clearance: 0.1-0.3mm (depending on size)

- Axial play: ≤ 0.5mm

- Smooth rotation with no binding through 90° travel

Common Rejection Points:

| Defect Type | D342X Impact | D343X Impact |

| Incorrect offset | Increased wear | Complete sealing failure |

| Seat misalignment | Leakage | Fire-safe failure |

| Bearing tightness | High torque | Cannot achieve zero-contact |

| Surface finish > Ra 3.2 | Reduced life | Galling/seizing |

Pre-Shipment Audit Trail:

INSPECTION RECORD MUST INCLUDE:

- Photographs (time-stamped):

- General view with serial number

- Offsets measurement

- Seat installation

- Testing setup

Test Data Logs:

- Pressure vs. time graphs

- Torque vs. angle graphs

- Leakage measurement records

Inspector Verification:

- Name/signature/date

- Instrument calibration dates

- Acceptance/rejection with

Final Release Criteria:

- All dimensional checks within tolerance

- All pressure tests passed with signed reports

- Functional tests show smooth operation

- Documentation complete and accurate

- Packaging meets export requirements

- No outstanding non-conformities

Resilient Seat Flanged Butterfly Valve Main dimensions(mm)

Note:1. Other specifications and flange standards are available upon request.

2.Design and specifications are subject to change without prior notice.

.png)

.png)