API Wcb Globe Valve

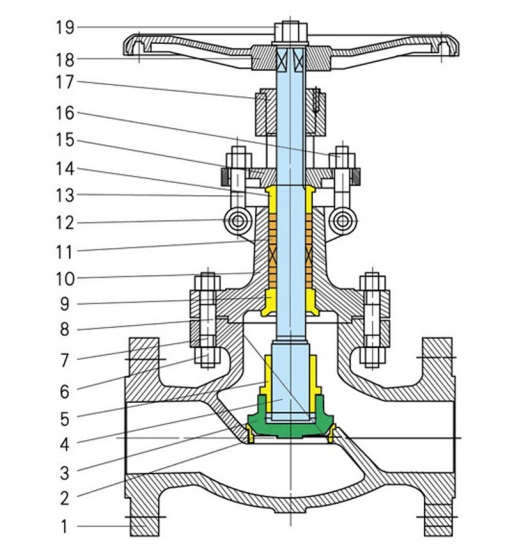

Wcb Globe Valve Parts and Material List

| Parts No. |

Parts Name | Materials | ||||

| WCB/Trim1 | WCB/Trim5 | WCB/Trim8 | CF8/304 | CF8M/316 | ||

| 1 | body | ASTM A216 WCB | ASTM A216 WCB | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M |

| 2 | Seat ring | A105+13Cr | A105+STL | A105+STL | ASTM A351 CF8 | ASTM A351 CF8M |

| 3 | Disc | ASTMA216 WCB+13Cr | ASTMA216 WCB+STL | ASTMA216 WCB+13Cr | ASTMA351 CF8 | ASTMA351 CF8M |

| 4 | Stem | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F304 | ASTM A182 F316 |

| 5 | Disc nut | ASTM A216 WCB | ASTM A216 WCB | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M |

| 6 | Bonnet nut | ASTM A1942H | ASTM A1942H | ASTM A1942H | ASTM A1948 | ASTM A1948M |

| 7 | Bonnet bolt | ASTM A193 B7 | ASTM A193 B7 | ASTM A193 B7 | ASTM A193 B8 | ASTM A193 B8M |

| 8 | Gasket | 304 sheet +Graphite | 304 sheet +Graphite | 304 sheet +Graphite | 304+Graphite | 316+Graphite |

| 9 | Backseat bushing | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a | ASTM A351 CF8 | ASTM A351 CF8M |

| 10 | Bonnet | ASTM A216 WCB | ASTM A216 WCB | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M |

| 11 | Packing | Graphite | Graphite | Graphite | Graphite | Graphite |

| 12 | Eyebolt pin | ASTM A36 | ASTM A36 | ASTM A36 | 304ss | 316ss |

| 13 | Gland eyebot | ASTM A193 B7 | ASTM A193 B7 | ASTM A193 B7 | ASTM A193 B8 | ASTM A193 B8M |

| 14 | Gland | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F304 | ASTM A182 F316 |

| 15 | Gland flange | ASTM A216 WCB | ASTM A216 WCB | ASTM A216 WCB | ASTM A351 CF8 | ASTM A351 CF8M |

| 16 | Eyebolt nut | ASTM A1942H | ASTM A1942H | ASTM A1942H | ASTM A1948 | ASTM A1948M |

| 17 | Stem nut | ASTM A439 D2 | ASTM A439 D2 | ASTM A439 D2 | ASTM A439 D2 | ASTM A439 D2 |

| 18 | Hand wheel | Ductile lron | Ductile Iron | Ductile lIron | Ductile Iron | Ductile Iron |

| 19 | Hand wheel nut | Carbon steel | Carbon steel | Carbon steel | Carbon steel | Carbon steel |

Note: The chart above only lists out some common composition of steel globe valve parts, We may provide other different parts material composition according to the customer's request or the actual valve working condition.

The Features of Wcb Globe Valve

Bolted Bonnet ; Outside Screw and Yoke; Rising stems; Metallic seating surfaces.

Stem Design

The stem is of integral forged design. The minimum diameter of the stem shall per the standard requirement.

Belleville Spring Loaded Packing Impacting System

If being requested by the customer, the Belleville spring loaded packing impacting system can be adopted for enhancing the durability and reliability of the packing seal.

Back Seating Design

All our globe valves have the back seating design. In most cases, the carbon steel globe valve is fitted with a renewable back seat. For stainless steel globe valve, the back seat is machined directly in the bonnet or is machined after welding. When the globe valve is at fully open position, the sealing of the back seat can be very reliable. However, as per the requirement of API, it is not advisable to add or change packing by the mean of back seating when the valve is pressure containing.

Seat

For carbon steel globe valve, the seat is usually forged steel. The sealing surface of the seat is spray welded with hard alloy specified by the customer. Renewable threaded seat is used for NPS≤10 globe valves, and welded on seat can be also optional if being requested by the customer. Welded on seat is used for NPS>12 carbon steel globe valves. For Stainless steel globe valve, integral seat is usually adopted, or to weld hard alloy directly integrally. Threaded or welded on seat is also optional for stainless steel global valve if being requested by the customer.

Stem Nut

Usually, the stem nut is made of ASTM A439 D2. It is also can be made of copper ally if being requested by the customer. For large sized globe valve, rolling bearing is fitted at the two sides of stem nut in order to minimize the open and close torque of the globe valve.

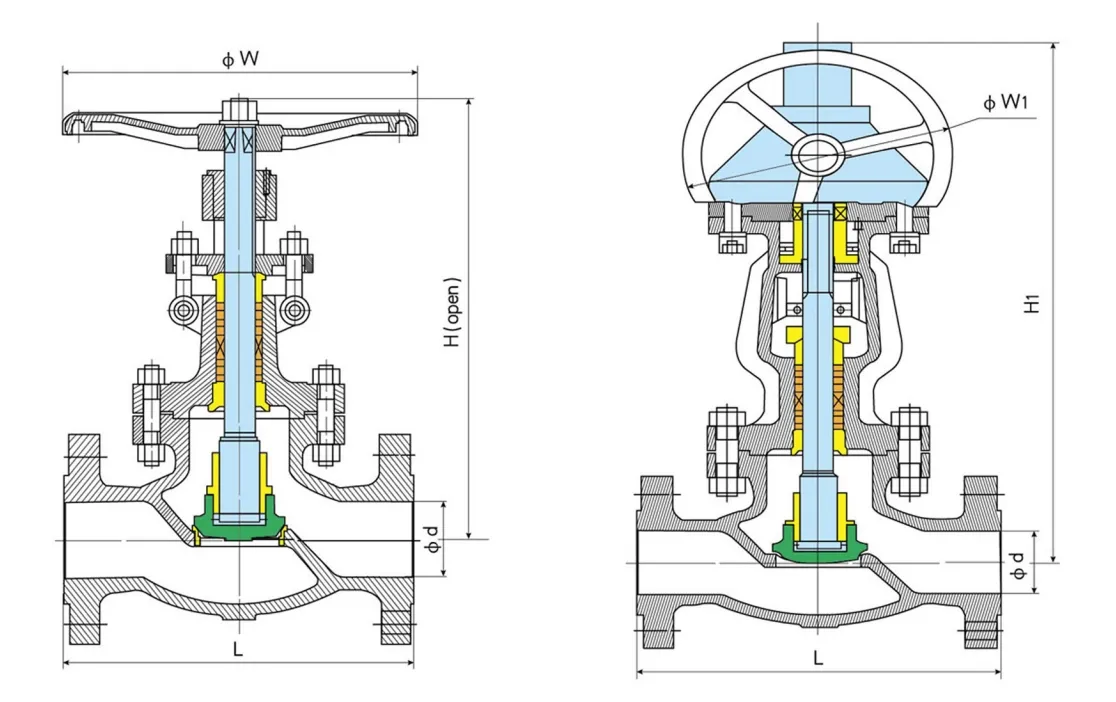

API GLOBE VALVE CLASS150

Class150 & JIS10K

Main Size of Outside & Weight

| Class | Size | Dimensions(mm) | Weight(kg) | |||||||||

| NPS | DN | L | d | H | H1 | W | W1 | Handwheel |

Gear box | |||

| RF | RTJ | BW | ||||||||||

| 150 | 1/2 | 15 | 108 | 119 | 108 | 13 | 182 | 一 | 100 | 一 | 3 | 一 |

| 3 | 20 | 117 | 130 | 117 | 19 | 193 | 一 | 100 | 一 | 4 | 一 | |

| 1 | 25 | 127 | 140 | 127 | 25 | 217 | 一 | 100 | 一 | 5 | 一 | |

| 11/4 | 32 | 140 | 152 | 140 | 32 | 235 | 一 | 135 | 一 | 8 | 一 | |

| 11/2 | 40 | 165 | 178 | 165 | 38 | 258 | 一 | 135 | 一 | 9 | 一 | |

| 2 | 50 | 203 | 216 | 203 | 51 | 330 | 一 | 200 | 一 | 19 | 一 | |

| 11/2 | 65 | 216 | 229 | 216 | 64 | 360 | 一 | 250 | 一 | 27 | 一 | |

| 3 | 80 | 241 | 254 | 241 | 76 | 390 | 一 | 280 | 一 | 36 | 一 | |

| 4 | 100 | 292 | 305 | 292 | 102 | 445 | 一 | 300 | 一 | 53 | 一 | |

| 5 | 125 | 356 | 369 | 356 | 127 | 480 | 一 | 350 | 一 | 75 | 一 | |

| 6 | 150 | 406 | 419 | 406 | 152 | 520 | 556 | 350 | 310 | 94 | 126 | |

| 8 | 200 | 495 | 508 | 495 | 203 | 600 | 659 | 400 | 310 | 148 | 180 | |

| 10 | 250 | 622 | 635 | 622 | 254 | 773 | 805 | 450 | 460 | 242 | 291 | |

| 12 | 300 | 698 | 711 | 698 | 305 | 880 | 955 | 500 | 460 | 438 | 480 | |

Class300 & JIS20K

Main Size of Outside & Weight

| Class | Size | Dimensions(mm) | Weight(kg) | |||||||||

| NPS | DN | L | d | H | H1 | W | W1 | Handwheel |

Gear box |

|||

| RF | RTJ | BW | ||||||||||

| 300 | 1/2 | 15 | 152 | 164 | 152 | 13 | 185 | 一 | 100 | 一 | 5 | 一 |

| 3/4 | 20 | 178 | 191 | 178 | 19 | 195 | 一 | 100 | 一 | 7 | 一 | |

| 1 | 25 | 203 | 216 | 203 | 25 | 220 | 一 | 135 | 一 | 10 | 一 | |

| 11/4 | 32 | 216 | 229 | 216 | 32 | 240 | 一 | 135 | 一 | 14 | 一 | |

| 11/2 | 40 | 229 | 241 | 229 | 38 | 260 | 一 | 160 | 一 | 19 | 一 | |

| 2 | 50 | 267 | 283 | 267 | 51 | 385 | 一 | 200 | 一 | 25 | 一 | |

| 21/2 | 65 | 292 | 308 | 292 | 64 | 420 | 一 | 200 | 一 | 42 | 一 | |

| 3 | 80 | 318 | 333 | 318 | 76 | 440 | 一 | 280 | 一 | 46 | 一 | |

| 4 | 100 | 356 | 371 | 356 | 102 | 515 | 一 | 350 | 一 | 74 | 一 | |

| 5 | 125 | 400 | 416 | 400 | 127 | 580 | 一 | 350 | 一 | 111 | 一 | |

| 6 | 150 | 444 | 460 | 444 | 152 | 660 | 690 | 400 | 310 | 165 | 195 | |

| 8 | 200 | 559 | 575 | 559 | 203 | 900 | 950 | 550 | 460 | 275 | 327 | |

| 10 | 250 | 622 | 638 | 622 | 254 | 950 | 990 | 600 | 460 | 400 | 452 | |

| 12 | 300 | 711 | 727 | 711 | 305 | 1030 | 1080 | 700 | 460 | 624 | 725 | |

Class600 & Class900

Main Size of Outside & Weight

Class |

Size | Dimensions(mm) | Weight(kg) | |||||||||

| NPS | DN | L | d | H | H1 | W | W1 | Handwheel |

Gear box |

|||

| RF | RTJ | BW | ||||||||||

| 600 | 2 | 50 | 292 | 295 | 292 | 51 | 360 | - | 250 | 一 | 32 | 一 |

| 21/2 | 65 | 330 | 333 | 330 | 64 | 410 | - | 280 | 一 | 42 | 一 | |

| 3 | 80 | 356 | 359 | 356 | 76 | 465 | - | 300 | 一 | 63 | 一 | |

| 4 | 100 | 432 | 435 | 432 | 102 | 545 | 575 | 400 | 310 | 107 | 138 | |

| 5 | 125 | 508 | 511 | 508 | 127 | 625 | 660 | 500 | 310 | 185 | 215 | |

| 6 | 150 | 559 | 562 | 559 | 152 | 785 | 820 | 550 | 460 | 290 | 342 | |

| 8 | 200 | 660 | 664 | 660 | 200 | 930 | 960 | 650 | 460 | 540 | 645 | |

| 900 | 2 | 50 | 368 | 371 | 368 | 47 | 480 | 一 | 350 | - | 55 | 一 |

| 21/2 | 65 | 419 | 422 | 419 | 57 | 520 | - | 350 | 一 | 68 | 一 | |

| 3 | 80 | 381 | 384 | 381 | 73 | 564 | 630 | 400 | 310 | 95 | 128 | |

| 4 | 100 | 457 | 460 | 457 | 98 | 685 | 720 | 450 | 310 | 160 | 210 | |

| 5 | 125 | 559 | 562 | 559 | 121 | 780 | 840 | 550 | 460 | 270 | 325 | |

| 6 | 150 | 610 | 613 | 610 | 146 | 950 | 1015 | 650 | 460 | 410 | 480 | |

Wcb Globe Valve Definition and Components

What is an API WCB Globe Valve and its main parts?

An API WCB Globe Valve is a type of linear motion valve designed for precise throttling and regulation of flow in demanding industrial pipelines, built to the standards of the American Petroleum Institute (API) with its primary pressure-retaining parts made of ASTM A216 Grade WCB carbon steel. Unlike gate valves designed for on/off service, its disc moves parallel to the seat, allowing fine control of the flow opening.

Main Parts:

- Body & Bonnet: The main casting, made of ASTM A216 WCB. The body has a characteristic Z-shaped or Y-shaped flow path. The bonnet is typically bolted and houses the stem sealing assembly.

- Disc (Plug): The primary closure element that moves perpendicular to the seat. The disc face is often flat or conical for tight shut-off.

- Stem: A rising stem that transmits motion from the actuator to the disc. The stem threads are typically outside the pressure boundary (OS&Y design).

- Seat Ring: A hardened, removable ring (often stainless steel or stellite-faced) that the disc seals against. The seat is integral to the body or pressed/welded in.

- Yoke & Yoke Nut/Sleeve: Connects the bonnet to the actuator and houses the stem threads.

- Packing Box: Contains multiple rings of braided graphite or PTFE packing, a gland, and a lantern ring (for sealant injection) to prevent stem leakage.

- Handwheel, Gear Operator, or Actuator: Manual or powered operation. Due to high operating forces, gear operators are common for larger sizes.

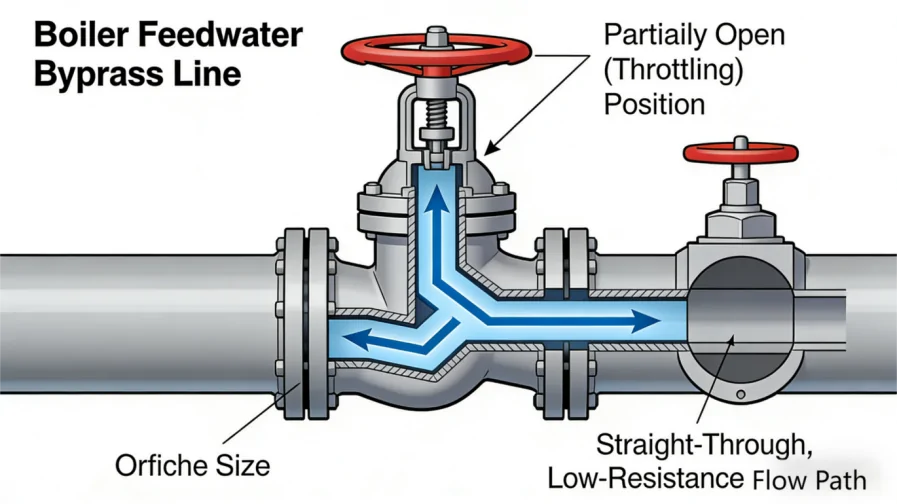

Role, Characteristics, and Application Scenarios of Wcb Globe Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Primarily designed for throttling/regulating flow and providing positive shut-off. It can precisely modulate flow rates and is effective for frequent operation.

Operational Features:

- Excellent Throttling: The disc-to-seat design allows for fine control of flow area with good linear characteristics.

- High Shut-off Capability: Provides tight sealing (bubble-tight when specified).

- High Pressure Drop: The tortuous flow path creates significant resistance, resulting in a higher pressure drop compared to gate or ball valves of the same size.

- High Stem Sealing Integrity: The design allows for effective, repairable stem packing.

- Fire-Safe Design: Can be designed per API standards (e.g., API 607) with secondary metal seals.

- Usage Scenarios: Used where flow control, isolation, and frequent adjustment are required.

- Boiler Feedwater Systems: For start-up, bypass, and drain applications.

- Cooling Water Systems: For flow balancing and control.

- Fuel Oil Systems: For flow regulation to burners.

- Chemical Injection & Metering Lines: For precise dosing control.

- Steam Service: For pressure let-down and isolation.

Wcb Globe Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

- Primary Material: ASTM A216 Grade WCB for body and bonnet.

- Trim Materials: Defined by API trim numbers. Common for globe valves is Trim 5 (Seat 13% Cr, Disc 13% Cr with Stellite face, Stem 13% Cr) or Trim 8 (all 13% Cr) for erosion/corrosion resistance.

- Design Standards: The core standard is API 602 ("Compact Design Carbon Steel Gate Valves for Petroleum and Natural Gas Industries") which covers small forged steel valves, and API 600 for larger cast steel valves. Globe valve design follows the pressure-temperature ratings of ASME B16.34.

Connection Standards:

- Flanged Ends: ASME B16.5 (Class 150, 300, 600, etc.) with RF or RTJ face.

- Butt-Weld Ends: ASME B16.25.

- Socket Weld or Threaded Ends: For smaller sizes (NPS 2 and below), per ASME B16.11.

- Face-to-Face: Dimensions per ASME B16.10.

How to Select Wcb Globe Valve

How to Purchase

- Define Critical Parameters: Specify size (NPS), pressure class (ASME Class), fluid, temperature, and the primary purpose (e.g., throttling vs. isolation). For throttling, specify required flow characteristics (linear, equal percentage).

- Source from API-Licensed Manufacturers: Procure from manufacturers holding the API Monogram License for API 602/600. Verify experience with globe valves specifically, as design differs from gate valves.

Request Detailed Technical Documentation: Submit an inquiry requesting:

- Technical datasheet with Cv (Flow Coefficient) values at different openings.

- Trim specification and material details.

- Certified dimensional drawings.

- Proof of API monogram and fire-test certification if required.

- Technical & Commercial Evaluation: Compare offers based on API compliance, throttling performance data, material specs, and lead time. The purchase order must explicitly reference API 602/600, material specs, trim, end connections, and test requirements.

Pre-Shipment Inspection for Export Wcb Globe Valve and Key Considerations

Pre-Export Inspection and Precautions

Industrial valves Inspection Protocol:

- Document Review: Verify API Monogram stamping and review Material Test Reports (MTRs) for body, bonnet, trim, and stem.

- Dimensional & Marking Check: Confirm face-to-face, flange dimensions, and proper markings (API symbol, size, class, material, flow direction arrow).

- Visual & Functional Check: Inspect the seat and disc for smooth machining. Operate the valve through its full stroke to ensure smooth movement without binding. Verify the disc and seat align correctly in the closed position.

- Witness API Pressure Testing: Testing per API 598 is mandatory:

- Shell Hydrostatic Test: At 1.5x rated pressure.

- Seat Leakage Test: Both upstream and downstream seats tested at 1.1x rated pressure. Globe valves are typically tested for leakage in the direction normal to flow closure.

- Optional Flow Test: For critical throttling applications, a flow characteristic test (Cv curve) may be requested.

Precautions:

- Ship in the Closed Position: To protect the seating surfaces.

- Protect Critical Surfaces: Apply anti-corrosion coating on stem and machined surfaces. Use sturdy flange protectors.

- Secure Internals: Ensure the disc is fixed to prevent movement during transit.

- Correct Orientation: Clearly mark the flow direction arrow on the crate. Globe valves are not bidirectional; flow must enter below the seat for standard designs.

- Complete Documentation: Ensure shipment includes: API Certified Test Reports, MTRs, Certificate of Conformity, installation manual (emphasizing flow direction), and packing list.

- Export Packing: Use robust wooden crates with internal bracing. Mark with "Flow Direction," "Lift Here," and "Keep Dry."

We also supply fire valve and water valves.

.png)

.png)