Bellow Seals Globe Valve

This Bellow Seal Globe Valve is widely applied to pipelines such as petroleum industry, chemical industry, medicine, power etc and the working pressure of the medium is 1,6/4,0 Mpa, working temperature of the medium is -20-350°C.

Bellow Seals Globe Valve Function and specification

| Type Tun. |

Nominal pressure (MPa) |

Testing pressure | Suitable temperature(℃) |

Suitable medium | |

| Strength(Water)(MPa) | Enclose(Water)(MPa) . |

||||

| DWJ41H-16 | 1.6 | 2.4 | 1.76 | -20℃-350℃ | Warter、Vapour、Oil |

| DWJ41H-25 | 2.5 | 3.75 | 2.75 | ||

| DWJ41H-40 | 4.0 | 6.0 | 4.4 | ||

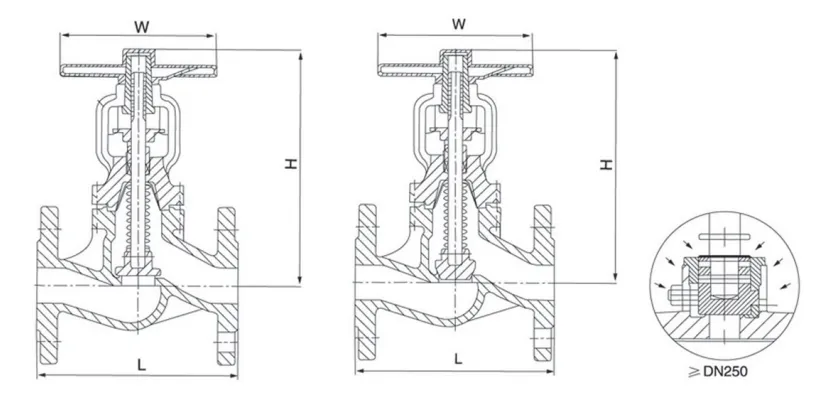

Bellow Seals Globe Valve Outline and connecting measurement

| Type | Nominal DN(mm) |

L | H | W | Bec | h | Kv |

| PN16 | 15 | 130 | 195 | 120 | 4 | 7 | 4.2 |

| 20 | 150 | 195 | 120 | 4.5 | 7 | 7.4 | |

| 25 | 160 | 207 | 140 | 5 | 12 | 12 | |

| 32 | 180 | 218 | 140 | 7 | 13 | 19 | |

| 40 | 200 | 225 | 160 | 9 | 14 | 30 | |

| 50 | 230 | 230 | 180 | 12 | 15 | 47 | |

| 65 | 290 | 272 | 180 | 18.5 | 19 | 77 | |

| 80 | 310 | 290 | 200 | 23 | 23 | 120 | |

| 100 | 350 | 355 | 250 | 38.5 | 28 | 188 | |

| 125 | 400 | 410 | 300 | 56 | 35 | 288 | |

| 150 | 480 | 425 | 300 | 75 | 42 | 410 | |

| 200 | 600 | 540 | 400 | 113.5 | 52 | 725 | |

| 250 | 730 | 665 | 520 | 235 | 64 | 1145 | |

| 300 | 850 | 720 | 520 | 395 | 75 | 1635 |

Bellow Seals Globe Valve Outline and connecting measurement

| Type | Nominal DN(mm) |

L | H | W | Bec | h | Kv |

| PN16 | 15 | 130 | 195 | 120 | 4 | 7 | 4.2 |

| 20 | 150 | 195 | 120 | 4.5 | 7 | 7.4 | |

| 25 | 160 | 207 | 140 | 5 | 12 | 12 | |

| 32 | 180 | 218 | 140 | 7 | 13 | 19 | |

| 40 | 200 | 225 | 160 | 9 | 14 | 30 | |

| 50 | 230 | 230 | 180 | 12 | 15 | 47 | |

| 65 | 290 | 272 | 180 | 18.5 | 19 | 77 | |

| 80 | 310 | 290 | 200 | 23 | 23 | 120 | |

| 100 | 350 | 355 | 250 | 38.5 | 28 | 188 | |

| 125 | 400 | 410 | 300 | 56 | 35 | 288 | |

| 150 | 480 | 425 | 300 | 75 | 42 | 410 | |

| 200 | 600 | 540 | 400 | 113.5 | 52 | 725 | |

| 250 | 730 | 665 | 520 | 235 | 64 | 1145 | |

| 300 | 850 | 720 | 520 | 395 | 75 | 1635 |

Bellow Seals Globe Valve Outline and connecting measurement

Type |

Nominal DN(mm) |

L | H | W | Bec | h | Kv |

| PN40 | 15 | 130 | 195 | 140 | 4 | 7 | 4.2 |

| 20 | 150 | 195 | 140 | 4.5 | 7 | 7.4 | |

| 25 | 160 | 207 | 140 | 6 | 12 | 12 | |

| 32 | 180 | 218 | 160 | 8 | 13 | 19 | |

| 40 | 200 | 225 | 180 | 11.5 | 14 | 30 | |

| 50 | 230 | 230 | 180 | 13.5 | 15 | 47 | |

| 65 | 290 | 272 | 200 | 20 | 19 | 77 | |

| 80 | 310 | 290 | 250 | 25 | 23 | 120 | |

| 100 | 350 | 355 | 300 | 45 | 28 | 188 | |

| 125 | 400 | 410 | 350 | 60 | 35 | 288 | |

| 150 | 480 | 425 | 350 | 83 | 42 | 410 | |

| 200 | 600 | 540 | 450 | 158 | 52 | 725 | |

| 250 | 730 | 665 | 520 | 305 | 64 | 1145 | |

| 300 | 850 | 720 | 520 | 440 | 75 | 1635 |

Bellow Seals Globe Valve Definition and Components

What is a Bellow Seals Globe Valve and its main parts?

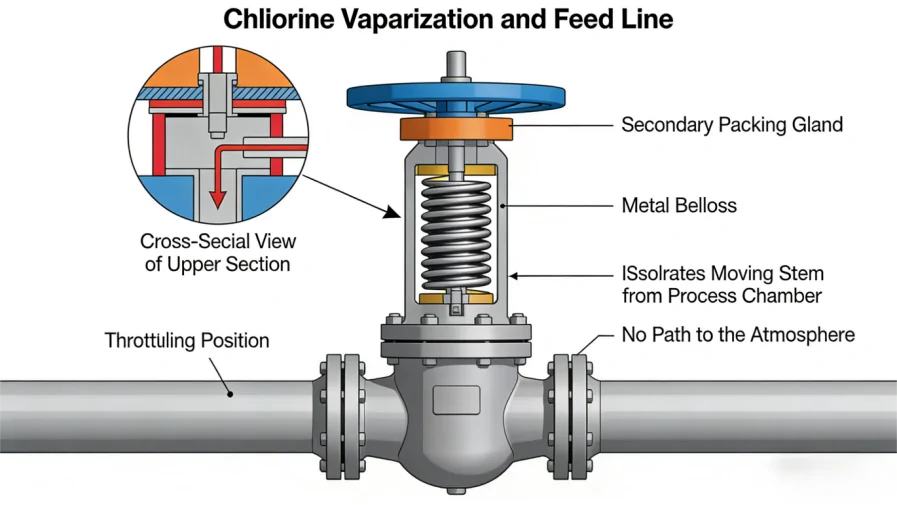

A Bellow Seals Globe Valve is a specialized type of globe valve designed for zero-emission service in handling toxic, hazardous, explosive, or expensive fluids. Its defining feature is a hermetically sealed, metallic bellows assembly that completely encapsulates the valve stem, replacing traditional gland packing and eliminating the primary path for external leakage.

Industrial valves Main Parts:

- Body & Bonnet: Standard globe valve body (Y-pattern or angle pattern) and bonnet, typically made of stainless steel or carbon steel.

- Disc (Plug) & Stem: The closure element connected to the stem. The stem is fully enclosed.

- Bellows Assembly: The core component. It consists of a stack of formed metal diaphragms (usually stainless steel 304/316L, Inconel 625) welded into a sealed, accordion-like unit. One end is welded to the stem and the other to the bonnet or a stationary part of the valve.

- Secondary (Back-up) Stem Seal: A set of conventional packing rings located above the bellows. It acts as a safety seal if the bellows fails and is also used during initial pressure testing.

- Seat Ring: The hardened or stellite-faced ring against which the disc seals.

- Actuator: Often a handwheel or gear operator, but pneumatic/hydraulic/electric actuators are common for automated critical processes.

Role, Characteristics, and Application Scenarios of Bellow Seals Globe Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Provides leak-tight shut-off and flow regulation while guaranteeing zero fugitive emissions from the stem area. It is used for isolation and throttling in critical services.

Operational Features:

- Zero Stem Leakage: The metal bellows forms a dynamic, hermetically sealed barrier between the process fluid and the atmosphere.

- Extended Cycle Life: Rated for a specified number of open/close cycles (e.g., 10,000+ cycles) before bellows fatigue.

- Reduced Maintenance: Eliminates the need for periodic gland packing adjustment or replacement.

- Higher Cost & Complexity: More expensive than packed valves due to the precision bellows assembly.

- Usage Scenarios: Mandatory in processes where leakage is unacceptable.

- Hazardous/Toxic Fluids: Chlorine, phosgene, hydrogen sulfide (H₂S), ammonia.

- Volatile Organic Compounds (VOCs) for environmental compliance.

- High-Purity or Ultra-Clean Systems: Semiconductor fabrication, pharmaceutical production, nuclear coolant lines.

- High-Temperature or Cryogenic Fluids: Where packing performance degrades.

- Expensive or Radioactive Media: Where loss is costly or dangerous.

Bellow Seals Globe Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

- Body/Bonnet: ASTM A216 WCB, ASTM A351 CF8/CF8M, ASTM A182 F316.

- Bellows: ASTM A312 / ASTM B167 / ASTM B564 for SS/Inconel/Hastelloy. Layers are hydraulically formed and welded.

- Seat/Disc: Often Stellite 6 or 12 overlay on stainless base.

- Design Standards: While specific to bellows valves, general design follows:

- API 602 (for forged steel) / API 600 (for cast steel).

- ISO 15848-1 (Fugitive Emissions Testing) – Class AH is the tightest rating.

- ASME B16.34 for pressure-temperature ratings.

- Bellows Design: Follows EJMA (Expansion Joint Manufacturers Association) standards for fatigue life calculation.

Connection Standards:

- Flanged: ASME B16.5 (RF, RTJ).

- Butt-Weld: ASME B16.25.

- Threaded/Socket Weld: ASME B16.11 (for small sizes).

How to Select Bellow Seals Globe Valve?

How to Purchase

- Define Critical Service Parameters: Fluid composition (aggressiveness, toxicity), temperature, pressure, required cycle life, and fugitive emission class (e.g., ISO 15848-1 Class AH).

- Identify Specialized Manufacturers: Source from valve makers with proven bellows valve expertise and ISO 15848 certification for their testing facilities. Reputation is crucial.

Request Detailed Technical Proposal: Ask for:

- Bellows Data Sheet: Material, number of plies, design cycle life, stroke length.

- Fugitive Emission Test Report from a third-party or certified lab.

- Material Traceability for bellows (heat numbers).

- Dimensional drawings and maintenance procedures.

- Evaluate and Order: Prioritize technical validation over price. Ensure the purchase order specifies the bellows cycle life warranty, emission class guarantee, and all referenced standards and test requirements.

Pre-Shipment Inspection for Export Bellow Seals Globe Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol (More Rigorous):

- Documentation Review: Scrutinize bellows material certificates and fugitive emission test certificates.

- Visual & Dimensional Check: Inspect for dents or damage on the bellows convolutions. Check overall dimensions

- Helium Leak Test (Critical): Witness a helium mass spectrometer leak test on the bellows assembly. This is the most sensitive test to verify hermetic integrity (e.g., leak rate < 1 x 10⁻⁶ mbar·l/s).

- Pressure Tests: Perform standard shell test and seat test per API 598. The secondary packing is used to test the seat.

- Function & Stroke Test: Cycle the valve slowly through its full stroke, observing bellows movement for smooth, uniform compression/extension without binding.

Precautions:

- Protect the Bellows: Install a rigid metal or plastic bellows guard for shipment and handling. Never lift the valve by the bellows assembly. Attach clear warning tags.

- Ship Position: Ship with the valve fully open to keep the bellows in a neutral, non-compressed state.

- Prevent Torsion: Ensure the valve is crated to prevent any twisting force on the stem/bellows.

- Controlled Environment: If possible, store and ship in a dry, clean environment to prevent bellows corrosion.

- Complete Documentation: Include Bellows Inspection Certificate, Helium Leak Test Report, Emission Test Report, and detailed installation/commissioning manual stressing bellows handling.

- Export Packing: Use rigid, custom-fit crating. Mark with "Fragile - Bellows Valve," "Do Not Lift from Stem," "Protect from Impact."

We also supply fire valve and water valves.

.png)

.png)