Flanged Resilient Seated OS&Y Gate Valve Model No. 1210

Flanged Resilient Seated OS&Y Gate Valve Model No. 1210 Definition and Components

Definition & Main Parts

A Flanged Resilient Seated OS&Y Gate Valve Model No. 1210 is a specific manufacturer's model of an outside screw and yoke gate valve designed for general industrial service. The "1210" designation typically indicates a particular design series or configuration from that manufacturer, often used in fire protection or industrial water systems.

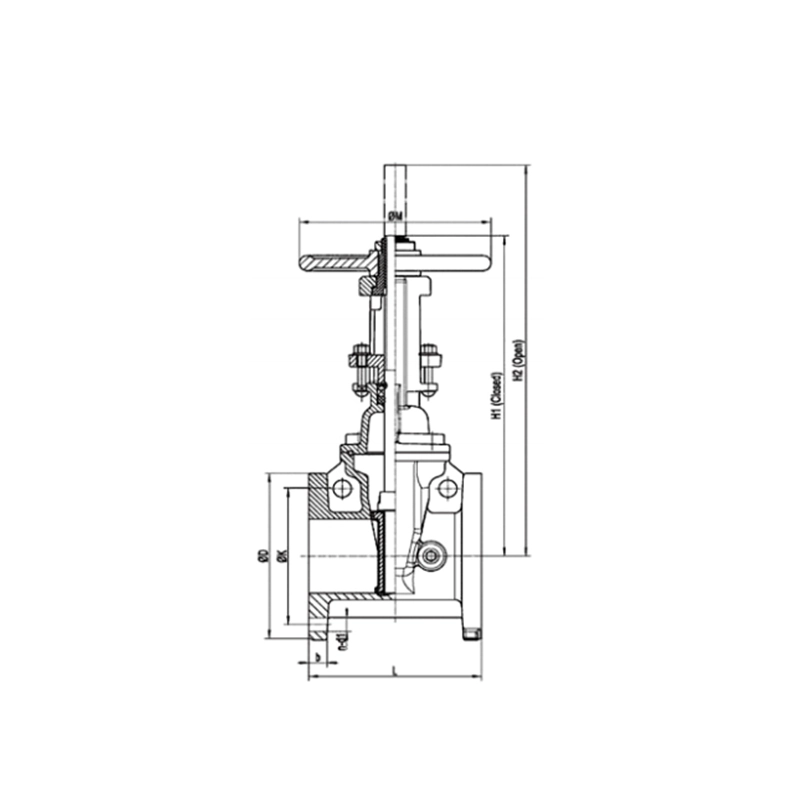

OS and Y Type Gate Valve Main Parts:

- Valve body with ANSI flanges

- Resilient-seated gate (rubber encapsulated)

- OS&Y assembly with visible rising stem

- Yoke, yoke bushing, and handwheel

- Adjustable gland packing system

- Body-bonnet bolting with full-face gasket

- Standard red or industrial gray coating

Role, Characteristics, and Application Scenarios of Flanged Resilient Seated OS&Y Gate Valve Model No. 1210 in Pipelines

Functions:

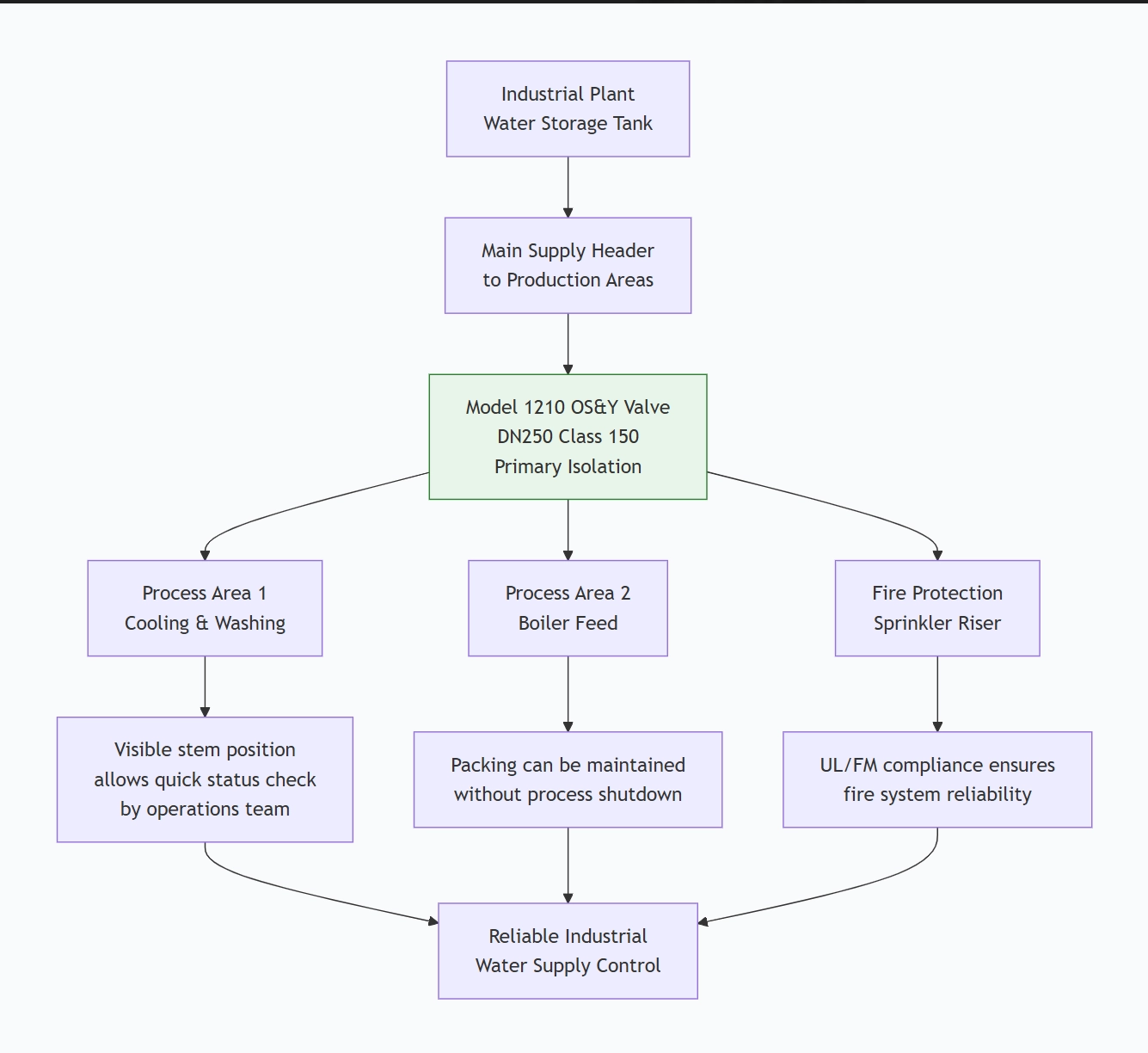

- Main isolation in fire protection systems

- Industrial water line control

- Pump station isolation valves

- High-reliability shutdown points

Fire gate valve Operational Features:

- Visual position indication (rising stem shows open/closed)

- Easy maintenance - packing adjustable while in service

- UL/FM listed typically for fire service

- Bubble-tight seal with resilient seat

- Industrial grade construction

Typical Applications:

- Fire sprinkler system mains

- Industrial process water lines

- Cooling water systems

- Water treatment plant piping

- Building service mains

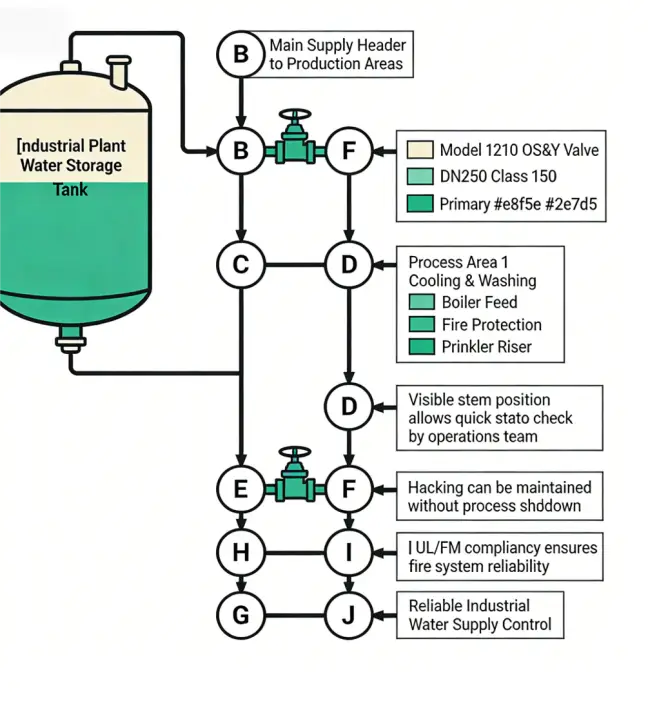

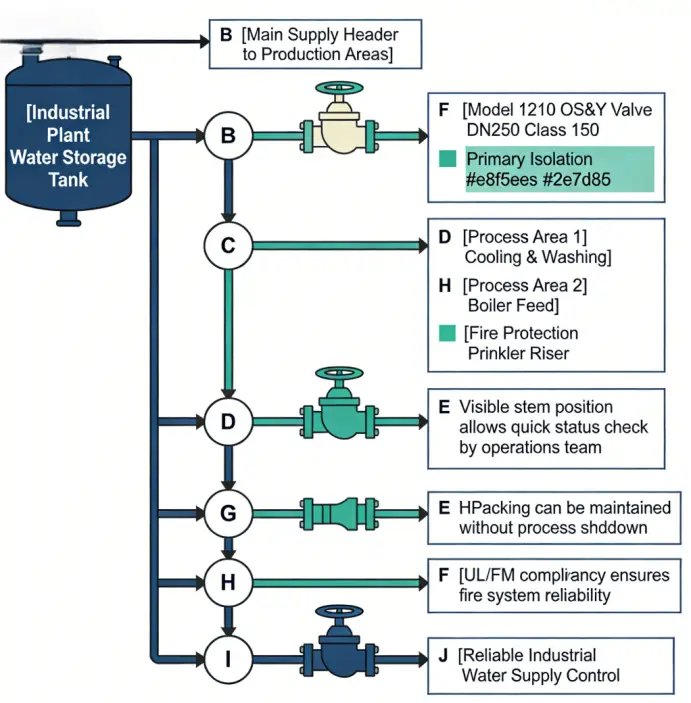

Scenario Diagram:

Flanged Resilient Seated OS&Y Gate Valve Model No. 1210 Standards: Materials, Design, and Connections

Fire valve Material Standards:

- Body/Bonnet: Ductile Iron ASTM A536 (Grade 65-45-12)

- Stem: Stainless Steel AISI 416

- Gate: Ductile iron with EPDM encapsulation

- Yoke: Cast iron or ductile iron

- Bolting: ASTM A307 Grade B

Design Standards:

- UL 262 or FM 1120 (for fire protection versions)

- MSS SP-70 (Cast iron gate valves)

- MSS SP-80 (Bronze gate valves - for trim)

- Pressure classes: Class 125, Class 150, Class 250

Connection Standards:

- Flanges: ANSI B16.1 Class 125 or Class 250

- Face-to-face: ANSI B16.10 Table 2 or MSS SP-70

- Gaskets: Full-face rubber per ANSI/AWWA C111

- Ends: Flanged x Flanged standard

How to Select Flanged Resilient Seated OS&Y Gate Valve Model No. 1210

Key Steps:

- Identify Service: Fire protection or industrial water

- Check Requirements: UL/FM listing needed for fire service

- Specify Details: Size, pressure class, end connections

- Select Supplier: Manufacturer with appropriate listings

- Verify Compliance: Request listing certificates

Critical Specifications:

- UL listing number (if for fire protection)

- Pressure class (Class 150 most common)

- Flange drilling (125# or 250#)

- Coating color (red for fire, gray for industrial)

- Position indicator type

Important Considerations:

- Confirm if valve needs UL/FM listing

- Check compatibility with existing systems

- Verify pressure rating matches system requirements

- Consider maintenance access requirements

Pre-Shipment Inspection for Export Flanged Resilient Seated OS&Y Gate Valve Model No. 1210 and Key Considerations

Documentation Check:

- UL Listing Certificate(if applicable)

- FM Approval Certificate(if applicable)

- Material Test Reports(ASTM compliance)

- Pressure Test Certificates

- Installation Instructions

Physical Inspection:

OS&Y Mechanism Check

Smooth rising stem operation

Full travel verification(open to close)

Yoke and stem alignment

Thread condition and protection

UL/FM Specific Requirements

Permanent marking of listing

Proper color coating(red for fire)

Tamper switch provisions if specified

Listed components verification

Pressure Testing

Shell test:2×rated pressure(300 psi for Class 150)

Seat test:1.1×rated pressure(165 psi for Class 150)

Backseat test capability

Packing leakage test

General Inspection

Complete assembly(all bolts,nuts)

Proper coating coverage

Clear identification markings

Flange face condition

Export Packaging:

- Flange protectors:Bolt-on type required

- Stem protection:Thread protectors on exposed stem

- Corrosion prevention:VCI bags for internal cavity

- Wooden crates:For larger sizes(DN150+)

- Color coding:For fire protection valves(red)

- Document pouch:Waterproof for certificates

Key Precautions:

- Listing labels:Protect UL/FM markings during shipping

- Stem protection:Prevent bending of long rising stems

- Moisture control:Extra desiccant for humid destinations

- Heavy items:Proper lifting points marked

- Documentation:Ensure all compliance papers included

Final Shipping Documents:

- Commercial Invoice

- Packing List with item details

- Bill of Lading

- Certificate of Origin

- Technical File(certificates,test reports)

- Installation&Maintenance Manual

- Material Certificates

Flanged Resilient Seated OS&Y Gate Valve Model No. 1210 Size Chart

| SIZE

Inch |

OUTLINE(Inch) | END FLANGE CIASS125 (Inch) | ||||||

| L | H1 | H2 | M | D | K | n-d1 | b | |

| 2 | 7 | 13.46 | 15.67 | 7 | 6.00 | 4.75 | 4-0.75 | 0.62 |

| 2 1/2 | 7.5 | 13.11 | 15.79 | 7 | 7.00 | 5.50 | 4-0.75 | 0.69 |

| 3 | 8 | 14.89 | 18.23 | 7 | 7.50 | 6.00 | 4-0.75 | 0.75 |

| 4 | 9 | 17.46 | 21.63 | 10 | 9.00 | 7.50 | 8-0.75 | 0.94 |

| 5 | 10 | 20.39 | 25.63 | 10 | 10.00 | 8.50 | 8-0.88 | 0.94 |

| 6 | 10.5 | 23.29 | 29.59 | 12 | 11.00 | 9.50 | 8-0.88 | 1.00 |

| 8 | 11.5 | 28.78 | 37.01 | 14 | 13.50 | 11.75 | 8-0.88 | 1.12 |

| 10 | 13 | 35.04 | 45.28 | 16 | 16.00 | 14.25 | 12-1.00 | 1.19 |

| 12 | 14 | 40.61 | 52.78 | 16 | 19.00 | 17.00 | 12-1.00 | 1.25 |

.png)

.png)