Lugged Type Wafer Butterfly Valve LTD371X

Lugged Type Wafer Butterfly Valve LTD371XPurpose

This valve is used as a cutoff and adjusting equipment for the various water supply and drainage pipelines in building chemical, medicine, textile, ship and other industries.

Lugged Type Wafer Butterfly Valve LTD371X Definition and Components

A Lugged Type Wafer Butterfly Valve Model LTD371X is a quarter-turn isolation valve featuring a gear-operated manual actuator mounted on a lugged wafer body. This combination provides mechanical advantage for operating larger valves under pressure while offering the installation flexibility of a lugged design. The "LTD371X" designation typically breaks down as: L = Lugged Body, T = Triple Offset (high-performance) or Thermal Resilient design, 3 = Gear Operator, 71 = Series Designation, X = EPDM Seat.

Main Parts:

- Lugged Body: Ductile iron or stainless steel body with threaded inserts or cast lugs for bolting to flanges.

- Gear Operator (Worm Gear Actuator): Manual handwheel that drives a worm gear to rotate the valve stem, providing high torque output.

- Disc: Offset or eccentric disc (typically stainless steel) designed for wear resistance and tight sealing.

- Resilient Seat (EPDM): An elastomer seat ring that provides bubble-tight shut-off.

- Stem: High-strength stainless steel shaft connecting the gear operator to the disc.

- Position Indicator: Shows disc position (0°, 45°, 90°).

- Stem Seals: Multiple PTFE or reinforced packing rings.

- Threaded Lugs: Allow valve to be bolted to one or both pipeline flanges.

Role, Characteristics, and Application Scenarios of Lugged Type Wafer Butterfly Valve LTD371X in Pipelines

Functions in Pipelines:

- High-Torque Isolation: Provides reliable shut-off for larger pipe sizes (typically DN150/6" and above) where lever operation would be difficult.

- Dead-End Service: Can be bolted to a single flange to isolate branch lines or equipment.

- Flow Regulation: The gear operator allows precise intermediate positioning for throttling applications.

- Bidirectional Sealing: Effective sealing against pressure from either direction.

Operational Features:

- Gear Operator Advantage: Provides 20:1 to 100:1 torque multiplication, making large valves operable by one person.

- Dead-End Service Capability: Rated for pressure on one side with the other side open to atmosphere.

- Position Locking: Most gear operators have provisions for padlocking in any position.

- Durability: Suitable for frequent operation in industrial environments.

- Temperature Range: Limited by EPDM seat (typically -20°C to 120°C).

Common Usage Scenarios:

- Industrial Water Lines: Main isolation valves for cooling water systems.

- Chemical Processing: Moderate chemical service where EPDM is compatible.

- HVAC Systems: Large diameter chilled/heating water lines.

- Fire Protection Systems: Pump discharge isolation.

- Power Plants: Auxiliary water systems.

Lugged Type Wafer Butterfly Valve LTD371X Standards: Materials, Design, and Connections

Material Standards:

- Body: ASTM A536 Ductile Iron (Grade 65-45-12) with epoxy coating, or ASTM A351 CF8M (316SS) for corrosive service.

- Disc: ASTM A743 CA-15 (410 SS) or CF8M (316 SS), often with hardened coating.

- Stem: AISI 316 Stainless Steel or 17-4PH (precipitation hardening).

- Seat: EPDM per ASTM D2000, FDA 21 CFR 177.2600 compliant if needed.

- Gearbox: Cast Iron Housing with Bronze Worm Gear and Steel Worm.

Design & Performance Standards:

- API 609: Primary standard for design and testing.

- ISO 5752: Face-to-face dimensions.

- API 598: Valve inspection and testing requirements.

- Fire Safe Design: API 607/ISO 10497 if required.

- Pressure Rating: Class 150 or PN16 standard. Must specify dead-end pressure rating separately.Connection Standards:

- Lug Design: Threaded for ANSI B16.5 bolt sizes. Common: UNC or 8UN threads.

- Flange Compatibility: ANSI Class 150 raised face flanges.

- Face-to-Face: API 609 or ISO 5752 short pattern.

- Gear Operator Mounting: ISO 5211 mounting pad standard

How to Select Lugged Type Wafer Butterfly Valve LTD371X

Technical Specification Development:

- Service Conditions: Fluid, temperature, pressure (including dead-end requirements).

- Size & Pressure Class: Pipe size (DN200, 8", etc.) and ANSI class.

- Material Specification: Body/disc material, seat type, gearbox material.

- Torque Requirements: Required operating torque based on size/pressure.

- Special Requirements: Fire-safe, cryogenic, or high-cycle needs.

Fire Protection Supply Company Qualification:

- Select manufacturers with API 609 certification.

- Request type testing certificates for fire-safe versions if needed.

- Evaluate gear operator quality - bronze gears preferred over nylon.

- Check dead-end pressure rating certification.

Documentation Requirements:

- Material Test Reports for body, disc, stem.

- API 598 test certificate with seat leakage rate.

- Dimensional drawings for approval.

- Torque charts for gear operator.

- Installation and maintenance manual.

Pre-Shipment Inspection for Export Lugged Type Wafer Butterfly Valve LTD371X and Key Considerations

Visual & Dimensional Inspection:

- Body coating uniformity and thickness (min. 250μm epoxy).

- Lug thread condition - check with go/no-go gauge.

- Gear operator smoothness - handwheel rotation effort.

- Nameplate information completeness.

- Face-to-face dimension verification.

Functional Testing Verification:

- Review API 598 test certificate for:

- Shell test pressure (1.5x rated pressure)

- Seat leakage test (maximum allowable leakage)

- Test duration and medium

- Witness or review video of functional test if possible.

Fire protection water supply Material Certification:

- Mill certificates for metallic components.

- Chemical analysis reports for stainless steel parts.

- Physical property tests for ductile iron.

Lugged Type Wafer Butterfly Valve LTD371X Main part materials

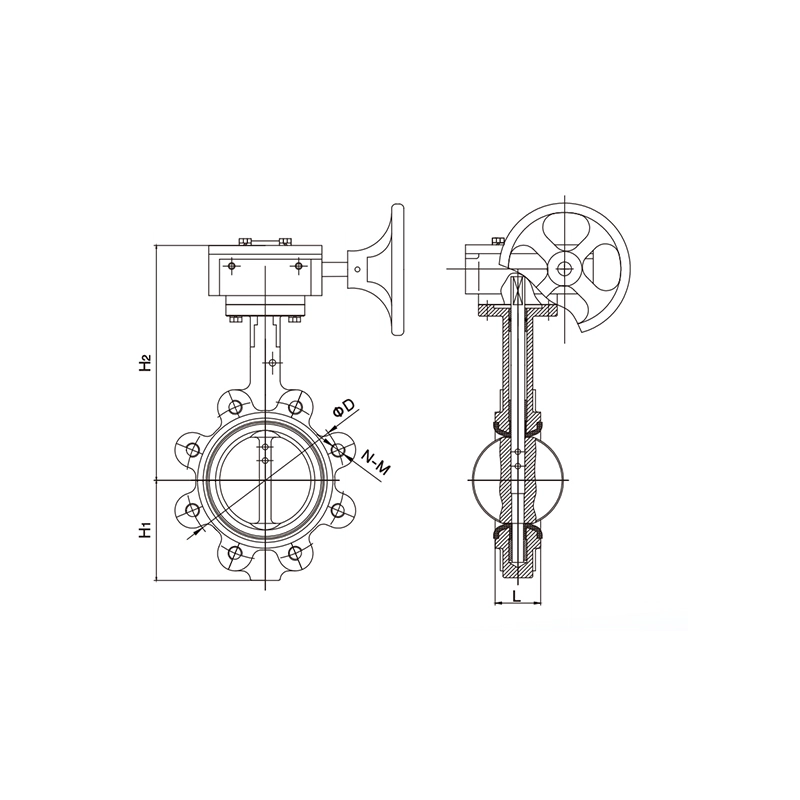

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| D | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 |

| N-M | 4-M16 | 4-M16 | 8-M16 | 8-M16 | 8-M16 | 8-M20 | 12-M20 | 12-M24 | 12-M24 |

| L | 43 | 46 | 46 | 52 | 56 | 56 | 60 | 68 | 74 |

| H1 | 70 | 78 | 90 | 102 | 122 | 150 | 174 | 208 | 240 |

| H2 | 199 | 207 | 214 | 241 | 255 | 270 | 309 | 366 | 411 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)