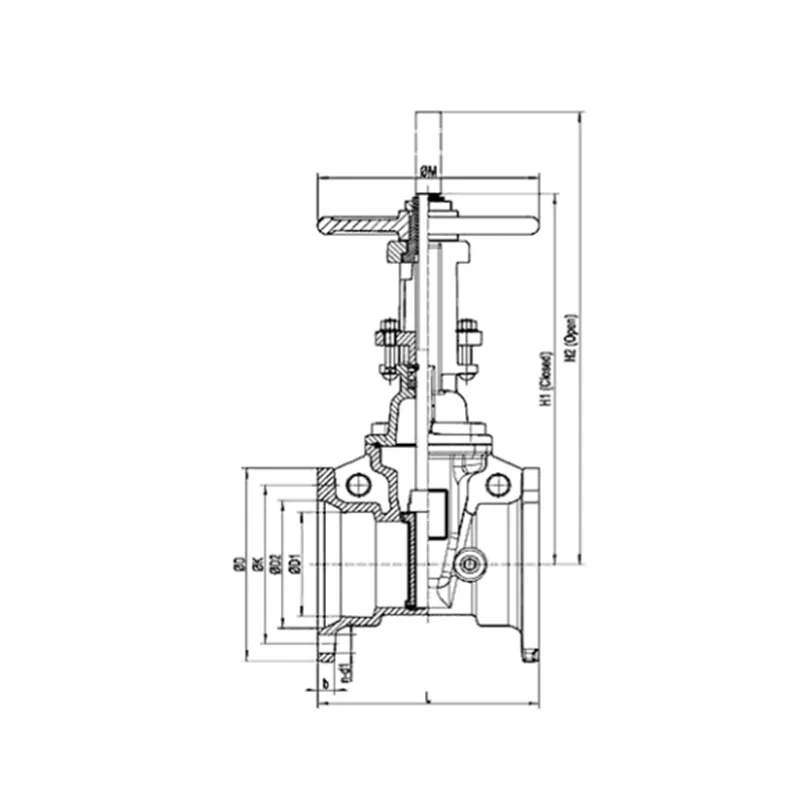

Mechanical Joint Resilient Seated OS&Y Gate Valve

Mechanical Joint Resilient Seated OS&Y Gate Valve Definition and Components

A Mechanical Joint (MJ) Resilient Seated OS&Y Gate Valve, Model 1212, is a specific type of valve designed for underground or submerged service in potable water distribution and fire protection systems. It is characterized by three key features:

- Mechanical Joint Ends:Allow for a bolted, gasketed connection to ductile iron pipe without threading or welding.

- Resilient Seat:An elastomer (rubber) seal bonded to the gate provides bubble-tight shut-off.

- OS&Y (Outside Stem & Yoke):The stem rises out of the yoke when opened, providing a clear visual indication of valve position.

Fire valve Main Parts:

- Valve Body (with cast MJ bell ends)

- Bonnet

- Resilient-Seated Gate (disc with rubber face)

- Stem (Rising, threaded)

- Yoke Assembly (with stem nut)

- Handwheel

- MJ Gland (Follower Ring), Bolts, and Tapered Rubber Gasket

- Stem Packing (Stuffing Box)

- Seat Ring (integral or mounted in body)

- Body Drain/Test Ports (optional)

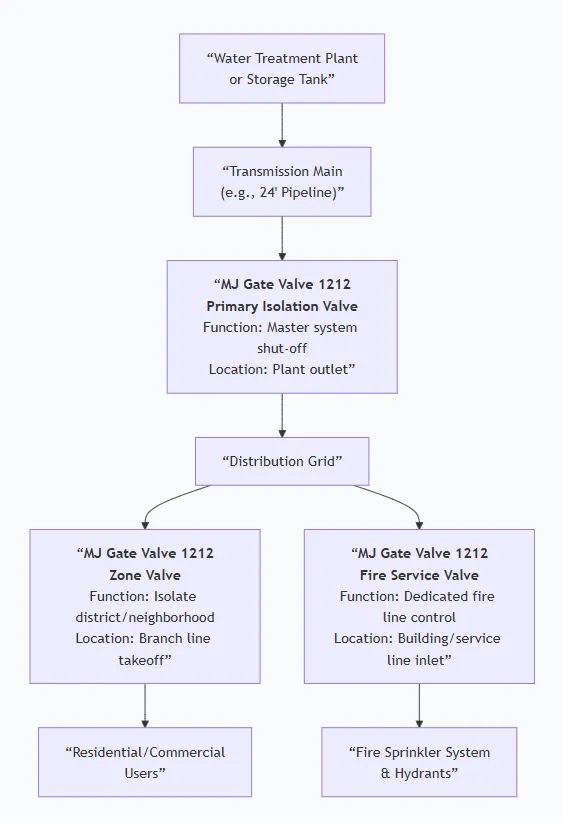

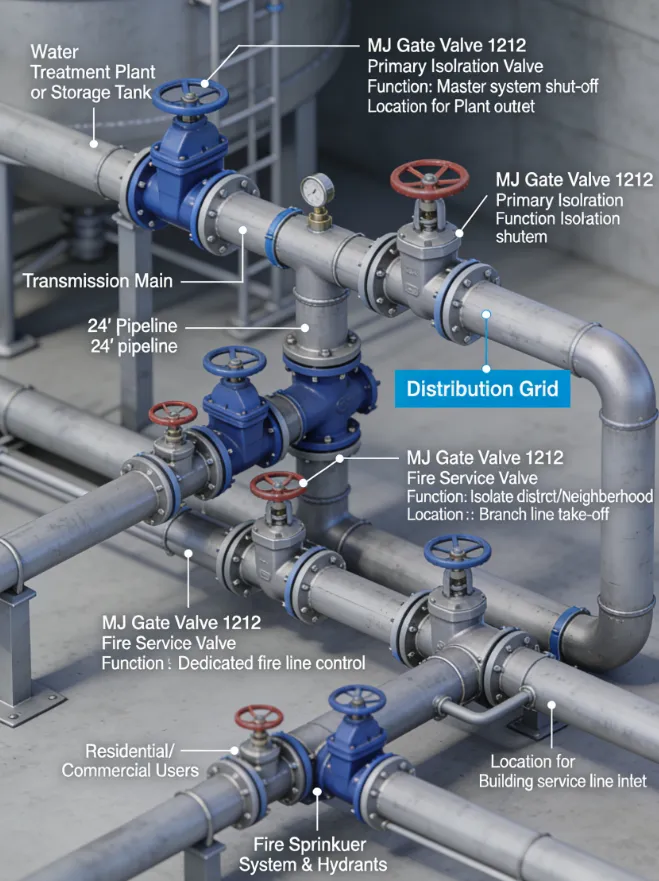

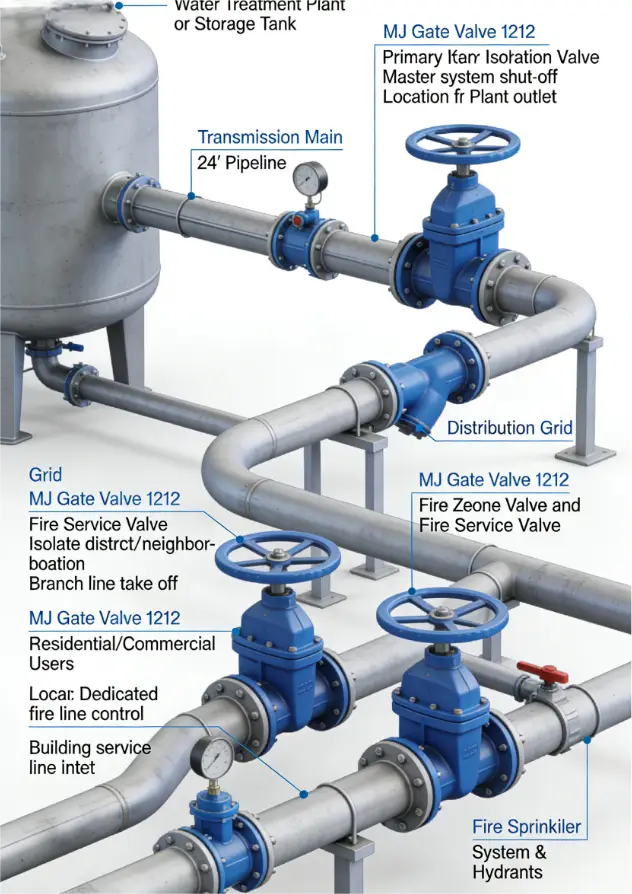

Role, Characteristics, and Application Scenarios of Mechanical Joint Resilient Seated OS&Y Gate Valve in Pipelines

Fire gate valve Functions:

- Isolation/Shut-Off:To completely stop flow in a pipeline for maintenance or emergency.

- Flow Direction:Suitable for bidirectional flow and sealing.

- System Sectionalizing:To divide a network into manageable segments.

Operational Features:

- Visual Position Indicator:The rising stem shows open/closed status at a glance.

- Bubble-Tight Sealing:Resilient seat ensures minimal leakage per AWWA standards.

- Low Operating Torque:Rubber-to-metal sealing requires less force than metal seats.

- Corrosion Resistant:Typically coated with fusion-bonded epoxy (AWWA C550).

- Field Adaptable:MJ connection accommodates minor pipe misalignment.

Primary Usage Scenarios:

This valve is standard in buried municipal and industrial water mains.

Scenario Diagram:

Mechanical Joint Resilient Seated OS&Y Gate Valve Standards: Materials, Design, and Connections

How to Select Mechanical Joint Resilient Seated OS&Y Gate Valve

Purchasing this specialized valve requires a technical focus to ensure proper function and longevity.

Step 1: Define Detailed Specifications

Create a procurement specification document including:

- Size & Pressure:Nominal Diameter (e.g., 12") and Pressure Class (e.g., 150 psi).

- Standards Compliance:Explicitly state: "Valve shall conform to AWWA C509."

- Materials:Specify body material (Ductile Iron per ASTM A536), epoxy coating per AWWA C550, and rubber compound (e.g., EPDM for potable water).

- Operation:Manual handwheel, or with extension stem and curb box for buried service.

- Testing & Certification:Require factory hydrostatic test reports and AWWA certification.

Step 2: Source and Evaluate Suppliers

- Identify manufacturers specializing in AWWA valves and authorized distributors.

- Request detailed submittals: product cut sheets, dimensional drawings, material certifications, and test reports.

- Evaluate based on technical compliance, project history, lead time, and cost.

Step 3: Quality Assurance & Logistics

- Consider third-party inspection (e.g., SGS, BV) for large orders.

- Finalize packaging (export crates) and documentation requirements (detailed packing lists, manuals, certificates).

Pre-Shipment Inspection for Export Valves and Key Considerations

OS&Y Gate Valve Specifications

Key Precautions for Export:

- Moisture Control:Ensure valve is completely dry and include desiccant bags inside packaging.

- Impact Protection:Use heavy-duty metal or plastic caps on MJ ends, secured with bolts. Protect the stem and handwheel with foam or cardboard.

- Secure Packing:Crate must prevent any movement during transit. Use hardwood skids and adequate blocking.

- Clear Marking:Label crates with item number, gross weight, handling symbols ("Keep Dry," "Top Lift," "This Side Up").

- Documentation Pack:Place a waterproof envelope containing copies of all critical documents (MTRs, test reports, manual) inside the crate.

.png)

.png)