Wcb Globe Valve

Wcb Globe Valve Definition and Components

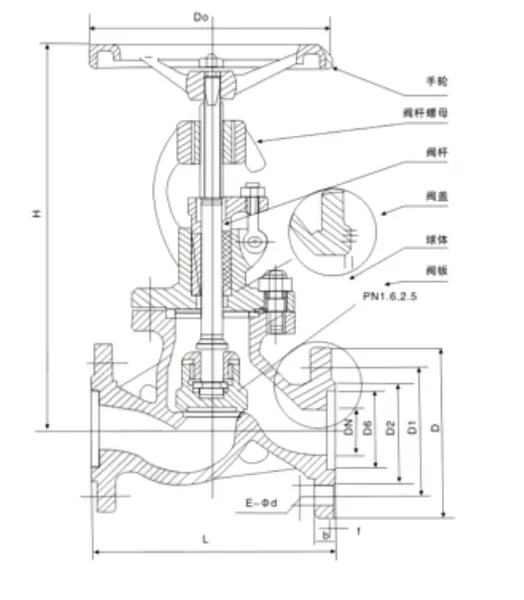

What is a WCB Globe Valve and its main parts?

A WCB Globe Valve is a type of linear motion valve primarily used for throttling (regulating) flow and providing reliable shut-off in industrial pipelines. The "WCB" designates that its primary pressure-containing components (body and bonnet) are made of ASTM A216 Grade WCB, a standard carbon steel casting material suitable for temperatures from -29°C to 425°C. Its name derives from its spherical body shape, and it features a disc that moves perpendicularly to the seat.

Main Parts:

- Body: The main pressure vessel, typically with a Z-shaped or Y-shaped internal flow path that forces the fluid to change direction, enabling good throttling control.

- Bonnet: The cover attached to the body, housing the stem sealing assembly. It is commonly bolted for ease of maintenance.

- Disc (or Plug): The movable element that presses against the seat to stop flow. Its face is often flat or tapered for tight sealing.

- Stem: The shaft that connects the actuator to the disc, transmitting force. Designs are usually rising stem (OS&Y).

- Seat Ring: The stationary ring against which the disc seals. It is often made of harder material (e.g., stainless steel) and can be replaceable.

- Yoke & Yoke Nut: The structural connection between the bonnet and the actuator, containing the stem threads.

- Packing Box: Contains packing material (e.g., graphite, PTFE) around the stem, compressed by a gland follower to prevent leakage to the environment.

- Handwheel / Actuator: For manual or automated operation.

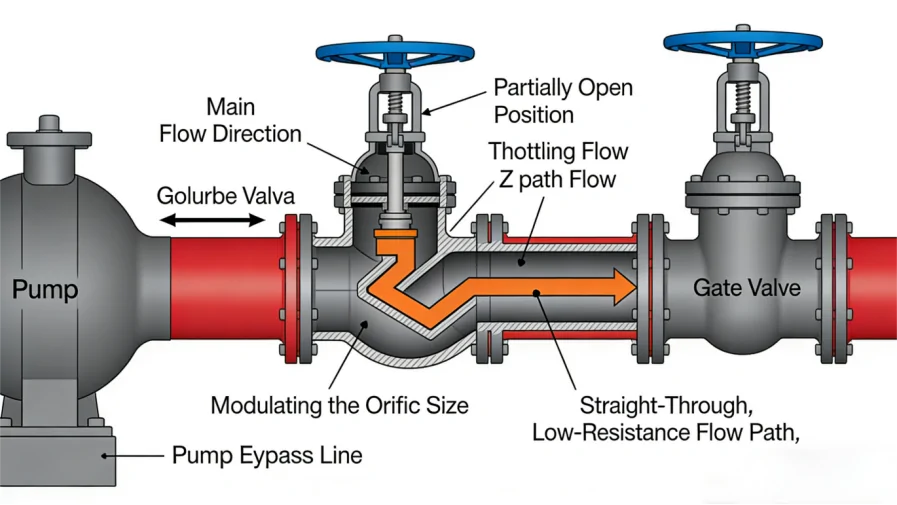

Role, Characteristics, and Application Scenarios of Wcb Globe Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions:

- Throttling / Flow Regulation: Excellent for precisely controlling flow rate.

- On/Off Isolation: Provides reliable shut-off, though with higher pressure drop than a gate valve

Operational Features:

- High Flow Resistance: The tortuous flow path creates significant pressure drop, even when fully open.

- Good Shut-Off Capability: The parallel disc-to-seat contact enables tight closure.

- Stem Sealing: The packing system allows for effective sealing and is repairable under pressure.

- Slower Operation & Higher Actuation Force: Requires more turns to operate than a quarter-turn valve, and stem forces can be high under pressure.

- Usage Scenarios: Ideal for services requiring frequent adjustment and tight sealing.

- Cooling Water Systems: For flow balancing and control.

- Feedwater & Chemical Dosing Lines: In power plants and process industries.

- Fuel Oil Systems: Regulation and isolation.

- Steam Service: For drain, vent, and bypass lines.

- General Utility Services (air, water, oil) where throttling is needed.

Wcb Globe Valve Standards: Materials, Design, and Connections

Material Standards:

- Body & Bonnet: ASTM A216 Grade WCB.

- Trim (Seat, Disc, Stem): Common materials include 13% Chrome stainless steel (e.g., 410 SS) for general service, or Stellite-faced for erosive/high-temperature service.

- Gaskets & Packing: Graphite, PTFE, or flexible graphite.

Design Standards:

- ASME B16.34: Fundamental standard for valve design, pressure-temperature ratings, and wall thickness.

- API 602 (for forged steel) / BS 1873 / MSS SP-80: Common manufacturing standards for globe valves.

- Face-to-Face Dimensions: ASME B16.10.

Connection Standards:

- Flanged: ASME B16.5 (Class 150, 300, etc.), typically with Raised Face (RF).

- Butt-Weld: ASME B16.25 for end preparation.

- Threaded/Socket Weld: ASME B16.11 (common for smaller sizes, NPS 2 and below)

How to Select Wcb Globe Valve

How to Purchase

Specify Requirements Clearly:

- Size (NPS/DN), Pressure Class (e.g., Class 150, 300).

- Fluid, Temperature, and Flow Rate (for throttling duty).

- Function (Isolation vs. Throttling).

- End Connection Type (Flanged, Welded, Threaded).

- Operation Method (Handwheel, Gear Operator, Actuator).

Identify Reputable Suppliers: Source from established valve manufacturers or authorized distributors. Check for quality management certifications (ISO 9001).

Request Technical Documentation: Ask for:

- Detailed datasheet with material specifications.

- Pressure-Temperature rating chart.

- Dimensional drawings (face-to-face, height, flange details).

- Certifications (if required for specific projects).

- Evaluate & Order: Compare technical compliance, price, lead time, and warranty. Ensure the purchase order lists all key specifications and standards.

Pre-Shipment Inspection for Export Wcb Globe Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Inspect for defects, verify markings (size, pressure, material, manufacturer). Check flange dimensions and face-to-face length.

- Material Verification: Review material certificates for body (A216 WCB) and critical trim parts.

- Pressure Testing (Critical): Witness shell test (1.5x rated pressure) and seat leakage test (1.1x rated pressure) per API 598 or ISO 5208. For globe valves, test sealing in the normal flow direction (pressure under the seat).

- Functional Test: Operate the valve fully open to closed, ensuring smooth stem movement and proper disc seating.

- Packing & Gasket Check: Verify packing is properly installed and gaskets are included.

Industrial valves Precautions:

- Shipping Position: Ship the valve in the fully closed position to protect the seating surfaces.

- Protect Critical Surfaces: Apply a temporary anti-corrosive coating on machined surfaces (stem, flange faces). Install protective caps/covers on flange ends and threaded connections.

- Correct Orientation: Clearly mark the flow direction arrow on the crate. Globe valves are directional; flow typically enters below the seat.

- Secure Internal Parts: Ensure the disc is fastened to prevent movement during transit.

- Packaging: Use sturdy, weather-resistant wooden crates. Securely brace the valve inside to prevent shifting. Include a waterproof pouch containing the packing list, test reports, certificates, and manual.

- Marking: Label the crate with handling instructions ("Lift Here," "Keep Dry"), gross weight, and part number.

Wcb Globe Valve Main parts and materials

| Parts name | Material | |||

| Valve body Bonnet | WCB | ZGCr5Mo | ZG1Cr18N9Ti | ZG1Cr18Ni12Mo2Ti |

| Disc | WCB | 25Cr2MoV | 1Cr18N9Ti | 1Cr18N12Mo2Ti |

| Stem | 2Cr13 | 25Cr2MoV | 1Cr18N9Ti | 1Cr18Ni12Mo2Ti |

| Packing | Flexible graphite | PTFE | ||

| Gasket | 18-8Flexible graphite | |||

| Bolt | 35/35CMo | 25Cr2MoV | 1Cr18N9Ti | 1Cr18N9 |

| Suitable temperature (C) | -29-425℃ | -29-425℃ | -40-200℃ | -40-200℃ |

| Suitable mediu | Water, oil, steam | Steam, oil | Nitrates acid | Acetic acid |

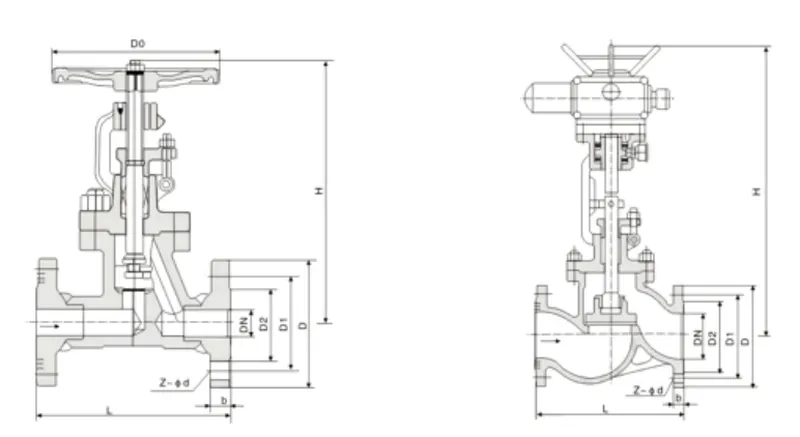

Wcb Globe Valve Outline and connecting measurement

| Type | Nominal DN |

PN1.6MPa | WT(kg) | ||||||||

| L | D | D1 | D2 | b | Z-φd | H | Do | J41 | J941 | ||

| J41H-16C J41Y-16C J418-16C J41W-16P J41Y-16P J41Y-16R J41Y-16 J941H-16C J941Y-16C J941B-16C J941W-16P J941Y-16P J941Y-16R J941Y-16 |

15 | 130 | 95 | 65 | 45 | 14 | 4-φ14 | 218 | 120 | 4.8 | 52 |

| 20 | 150 | 105 | 75 | 55 | 14 | 4-φ14 | 258 | 140 | 65 | 7.1 | |

| 25 | 160 | 115 | 85 | 65 | 14 | 4-φ14 | 275 | 160 | 7.0 | 7.4 | |

| 32 | 180 | 135 | 100 | 78 | 15 | 4-φ18 | 280 | 160 | 82 | 8.5 | |

| 40 | 200 | 145 | 110 | 85 | 16 | 4-φ18 | 330 | 200 | 11.0 | 12.5 | |

| 50 | 230 | 160 | 125 | 100 | 16 | 4-φ18 | 350 | 200 | 14.5 | 20 | |

| 65 | 290 | 180 | 145 | 120 | 18 | 4-618 | 380 | 240 | 21.5 | 25 | |

| 80 | 310 | 195 | 160 | 135 | 20 | 8-φ18 | 400 | 240 | 27 | 35 | |

| 100 | 350 | 215 | 180 | 155 | 20 | 8-φ18 | 415 | 280 | 30 | 50 | |

| 125 | 400 | 245 | 210 | 185 | 22 | 8-φ18 | 460 | 320 | 84 | 75 | |

| 150 | 480 | 280 | 240 | 210 | 24 | 8-φ23 | 510 | 360 | 91 | 100 | |

| 200 | 600 | 335 | 295 | 265 | 26 | 12-φ23 | 710 | 360 | 148 | 210 | |

| 250 | 650 | 405 | 355 | 320 | 30 | 12-φ23 | 786 | 450 | 405 | 446 | |

| 300 | 750 | 460 | 410 | 375 | 30 | 12-φ23 | 925 | 500 | 610 | 648 | |

Wcb Globe Valve Outline and connecting measurement

| Type | Nominal DN |

PN2.5MPa | WT(kg) | |||||||

| L | D | D1 | D2 | b | 2-φd | H | Do | |||

| J41H-25 J41Y-25 J41B-25 41W-26P 41Y-25P J41Y-25R J41Y-251 J941H-25 J941Y-25 9418-25 J941W-25P J941Y-25P J941Y-25R J941Y-251 |

15 | 130 | 95 | 65 | 45 | 16 | 4-φ14 | 218 | 120 | 5 |

| 20 | 150 | 105 | 75 | 55 | 16 | 4-φ14 | 258 | 140 | 6.9 | |

| 25 | 160 | 115 | 85 | 65 | 16 | 4-φ14 | 275 | 160 | 7.4 | |

| 32 | 180 | 135 | 100 | 78 | 18 | 4-φ18 | 280 | 180 | 8.5 | |

| 40 | 200 | 145 | 110 | 85 | 18 | 4-φ18 | 330 | 200 | 12.5 | |

| 50 | 230 | 160 | 125 | 100 | 20 | 4-φ18 | 350 | 240 | 16 | |

| 65 | 290 | 180 | 145 | 120 | 22 | 8-φ18 | 400 | 280 | 25 | |

| 80 | 310 | 195 | 160 | 135 | 22 | 8-φ18 | 355 | 280 | 30 | |

| 100 | 350 | 230 | 190 | 160 | 24 | 8-φ23 | 415 | 320 | 34.5 | |

| 125 | 400 | 270 | 220 | 188 | 28 | 8-φ25 | 460 | 400 | 89 | |

| 150 | 480 | 300 | 250 | 218 | 30 | 8-φ23 | 510 | 400 | 98 | |

| 200 | 600 | 360 | 310 | 278 | 34 | 12-φ25 | 710 | 400 | 170 | |

| 250 | 650 | 425 | 370 | 332 | 36 | 12-φ30 | 786 | 450 | 446 | |

| 300 | 750 | 485 | 430 | 390 | 40 | 12-φ30 | 926 | 500 | 654 | |

We also supply fire valve and water valves.

.png)

.png)