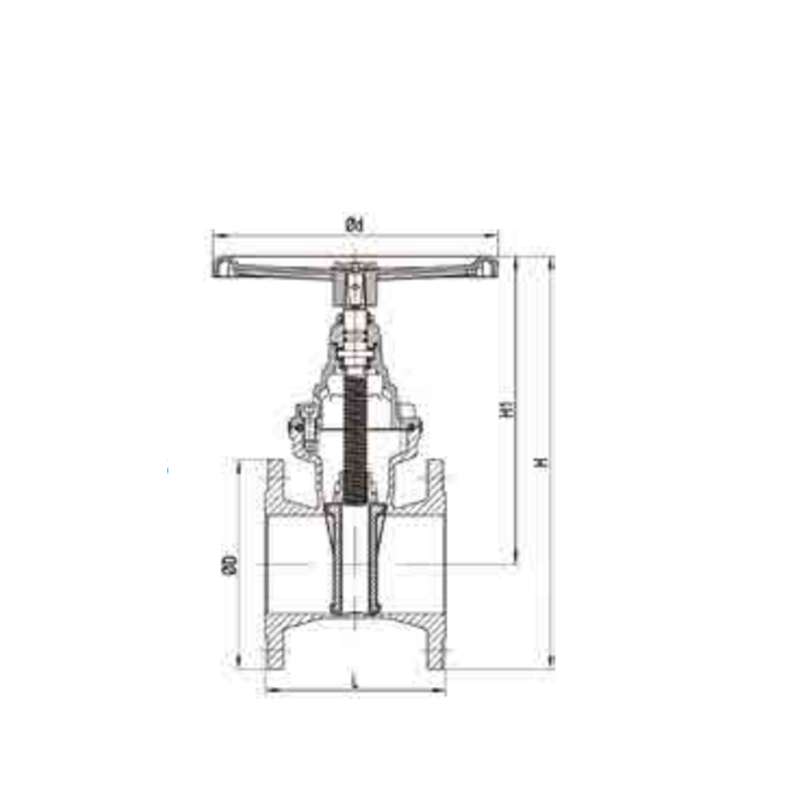

DIN F4 Flanged Resilient Seated NRS Gate Valve

DIN F4 Flanged Resilient Seated NRS Gate Valve Definition and Components

A DIN F4 Flanged Resilient Seated NRS Gate Valve Model No.Z45X-01 is a European standard gate valve with DIN F4 flange connections. It complies with German/European standards featuring a grooved flange face(F4)and non-rising stem(NRS)design. Model Z45X-01 decodes as: Z=Gate valve,45=Flanged, X=Resilient seated,01=Design version.

Main Parts:

Valve body with DIN F4 flanges(grooved face with concentric serrations)

Resilient-seated gate with full rubber encapsulation

Non-rising stem assembly

Handwheel or gear operator

Body-bonnet bolting with gasket

Stem packing system

Internal and external protective coatings

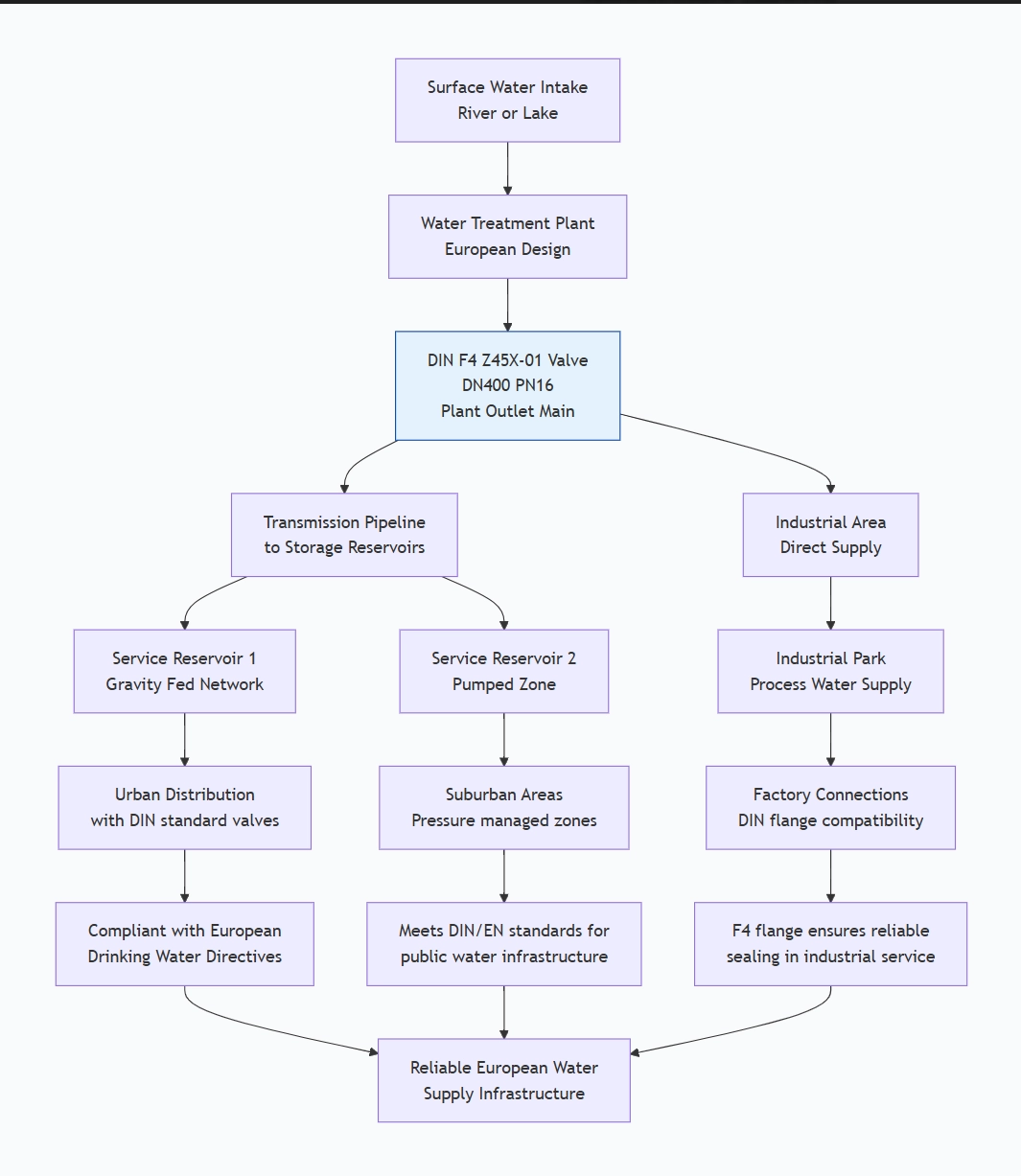

Role, Characteristics, and Application Scenarios of DIN F4 Flanged Resilient Seated NRS Gate Valve in Pipelines

Fire gate valve Functions:

Mainline isolation in European water distribution systems

Industrial process line shut-off

Pump station control valves

Water treatment plant process valves

Operational Features:

DIN F4 flange connection for excellent gasket retention

Bubble-tight seal per DIN EN 12266-1

Compact installation with non-rising stem

Low operating torque with resilient seat

European standard compliance for continental projects

Typical Applications:

Municipal water networks in Europe

Industrial water supply systems

Wastewater treatment plants

Fire protection systems in EU countries

Building services in German-speaking regions

Scenario Diagram:

DIN F4 Flanged Resilient Seated NRS Gate Valve Standards: Materials, Design, and Connections

Material Standards:

Body/Bonnet: Ductile Iron EN-GJS-500-7 per DIN EN 1563

Stem: Stainless Steel 1.4021/1.4057 per DIN EN 10088-3

Gate: Ductile iron with EPDM encapsulation

Seat Material: EPDM per DIN EN 681-1

Bolting: Grade 8.8/10.9 per DIN EN ISO 898-1

Coatings: Internal epoxy per relevant European standards

Design Standards:

DIN EN 1074-Fitness for purpose requirements for water supply valves

DIN EN 12266-1-Pressure testing requirements

DIN 3202-Face-to-face dimensions

DIN 2501-Pressure nominal(PN)designations

DVGW/W270-German drinking water approval

Connection Standards:

Flanges: DIN EN 1092-2 Type F4(grooved face with concentric serrations)

Gaskets: Full-face type compatible with F4 groove pattern

Pressure Ratings: PN10,PN16,PN25,PN40

Face-to-Face: DIN 3202-F4/F5 series dimensions

How to Select Such Fire Valve

Key Steps:

Specify DIN Standards Compliance: Mandatory for European projects

Verify F4 Flange Requirement: Confirm groove face type needed

Check Drinking Water Approvals: DVGW,KTW,ACS as required by country

Select Supplier: Manufacturer with DIN/EN certification experience

Request Documentation: DIN EN 10204 3.1 material certificates

Critical Specifications:

DIN EN 1074 compliance confirmation

F4 flange face specification(must be explicitly stated)

Pressure rating(PN16,PN25 common)

Drinking water approval requirements(country-specific)

Face-to-face dimensions(DIN 3202 series)

Important Considerations:

F4 flanges require matching gaskets with correct groove pattern

Verify manufacturer has European drinking water approvals

Check for specific country requirements(Germany, France, etc.)

Confirm all materials comply with relevant EU directives

Pre-Shipment Inspection for Export DIN F4 Flanged Resilient Seated NRS Gate Valve and Key Considerations

Documentation Check:

DIN EN 1074 Certificate of Compliance

Material Test Reports per DIN EN 10204 3.1

Drinking Water Approval Certificates(DVGW,KTW,ACS,WRAS)

Pressure Test Certificates per DIN EN 12266-1

CE Marking documentation

Factory test reports

Physical Inspection:

DIN F4 Flange Verification

F4 groove pattern inspection(concentric serrations)

Flange thickness and drilling per DIN EN 1092-2

Groove depth and width measurements

Surface finish quality check

Pressure Testing(per DIN EN 12266-1)

Shell test:1.5×PN(24 bar for PN16)

Seat test:1.1×PN(17.6 bar for PN16)

Test duration minimum 60 seconds

Zero visible leakage requirement

European Standard Compliance

Proper marking per DIN standards

Face-to-face dimensions per DIN 3202

Material grade verification

Drinking water compliance marking

Operational &Visual Inspection

Smooth non-rising stem operation

Complete assembly verification

Coating thickness and coverage

Protection of all machined surfaces

Export Packaging:

F4 flange protectors: Bolt-on rigid covers mandatory(F4 grooves easily damaged)

Stem protection: Thread protectors on stem

Internal VCI protection: For sea transport

Climate-appropriate packaging: Extra protection for humid/marine destinations

Wooden crates: Heavy-duty for larger valves

Document pouch: Waterproof for certificates

Key Precautions:

F4 face protection: Critical-serrated faces are easily damaged

Drinking water certification: Documents must accompany shipment

EU compliance: Ensure all markings meet European market requirements

Documentation: Complete set of DIN/EN certificates required

Lifting: Proper lifting points marked, never lift by handwheel

Final Shipping Documents:

Commercial Invoice with detailed description

Packing List with valve serial numbers

Bill of Lading

Certificate of Origin

Complete Technical File(DIN certificates, test reports, approvals)

Installation, Operation& Maintenance Manual(multi-language if needed)

Material Certificates(DIN EN 10204 3.1)

DIN F4 Flanged Resilient Seated NRS Gate Valve Size Chart

DN600 available upon request

.png)

.png)