Mechanical Joint Resilient Seated NRS Gate Valves

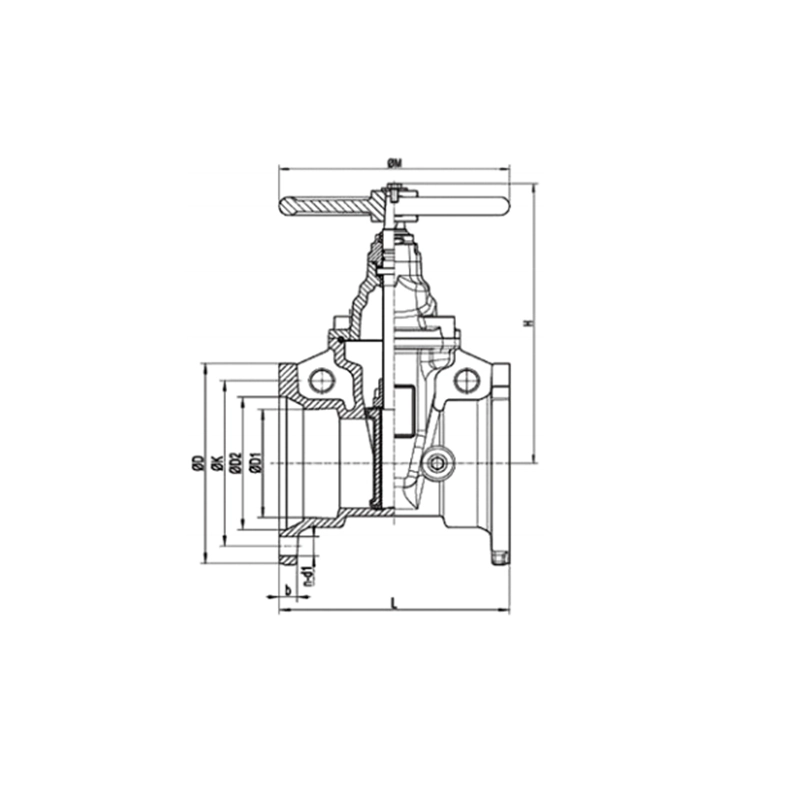

Mechanical Joint Resilient Seated NRS Gate Valves Definition and Components

A Mechanical Joint (MJ) Resilient Seated NRS Gate Valve Model 1112 is designed by nrs gate valves supplier for ductile iron pipe systems using mechanical joint connections instead of flanges. "1112" indicates manufacturer's model (1=gate valve, 1=mechanical joint, 12=design series).

Fire gate valve Main Parts:

Body: Ductile iron with integral MJ bell ends

Gate: Ductile iron core with full rubber encapsulation (EPDM/NBR)

Stem: Stainless steel, non-rising type

MJ Connection Components: Gland, bolts, nuts, gasket

Bonnet: Bolted to body

Stem Nut & Handwheel: For manual operation

Packing System: Stem seals

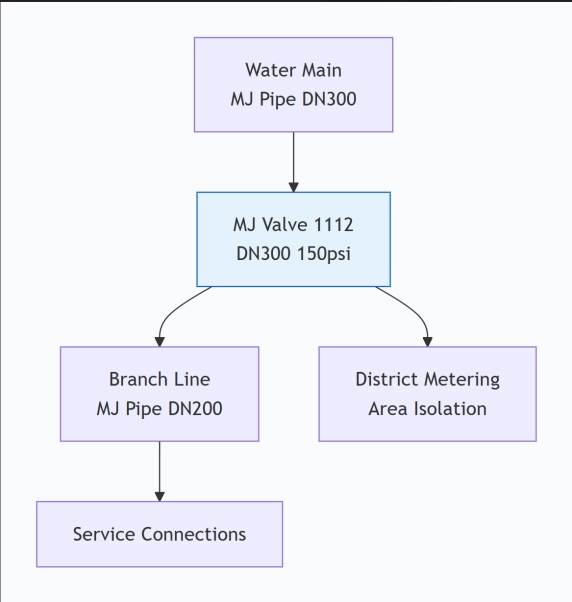

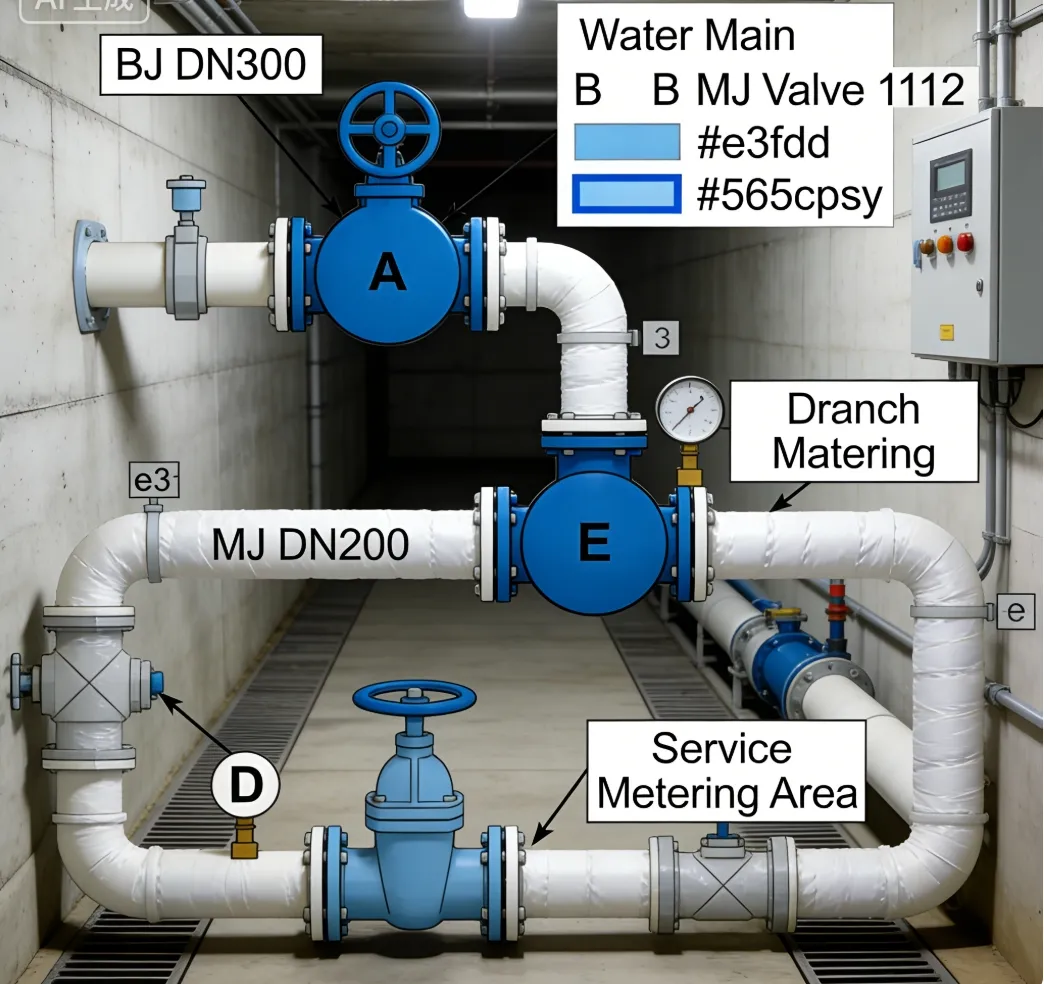

Role, Characteristics, and Application Scenarios of Mechanical Joint Resilient Seated NRS Gate Valves in Pipelines

Functions:

Isolation/on-off control in water distribution

Connection between MJ piping systems

Zone control and isolation

Fire Valve Operational Features:

Mechanical Joint connection - bolts directly to MJ pipe

Resilient seated - bubble-tight seal

Non-rising stem - compact installation

Full port - minimal pressure drop

Typical Applications:

Municipal water distribution networks

Fire protection systems

Industrial water lines

Irrigation systems

Scenario Diagram:

Mechanical Joint Resilient Seated NRS Gate Valves Standards: Materials, Design, and Connections

Material Standards:

Body/Gate: ASTM A536 ductile iron (65-45-12)

Stem: ASTM A276 416 stainless steel

Bolts: ASTM A307 Grade B

Gasket: EPDM per ASTM D2000

Coatings: AWWA C550 epoxy interior

Design Standards:

AWWA C500 or AWWA C509

Pressure: 150psi or 200psi

Face-to-face per AWWA standards

Connection Standards:

Mechanical Joint: AWWA C111 (ANSI/AWWA C111/A21.11)

Dimensions: Per AWWA C110 (ANSI/AWWA C110/A21.10)

MJ Gland: Cast ductile iron

Gasket: MJ push-on type

How to Select Mechanical Joint Resilient Seated NRS Gate Valves

Key Steps:

Specify: Size (DN/NPS), pressure rating, material requirements

Verify Standards: AWWA C500/C509 compliance

Check Certifications: NSF/61 for potable water

Supplier Selection: AWWA-approved manufacturers

Documentation: Request AWWA compliance certificates

Lead Time: Typically 8-12 weeks

Critical Specifications:

Valve size (NPS 3" to 48")

Pressure class (150psi standard)

End type: Mechanical Joint both ends

Material certifications required

AWWA standards compliance

Pre-Shipment Inspection for Export Mechanical Joint Resilient Seated NRS Gate Valves and Key Considerations

Inspection Checklist:

Documentation:

AWWA compliance certificate

Material test reports

NSF/61 certification

Hydrostatic test reports

Physical Inspection:

Dimensional Check:

Face-to-face measurement

MJ bell dimensions

Bolt circle verification

Pressure Testing:

Shell test: 300psi (2×150psi)

Seat test: 165psi (1.1×150psi)

No visible leakage

Visual Inspection:

Casting quality

Coating thickness (8-12 mils)

Proper marking ("MJ", size, pressure)

Operational Test:

Smooth open/close operation

NRS function verified

Export Packaging:

MJ bell protectors (plastic/metal)

VCI bags in valve cavity

Desiccant packs

Wooden crate for protection

Lifting points clearly marked

Key Precautions:

Protect MJ bell ends during transport

Include installation instructions for MJ assembly

Ensure gaskets and bolts are included

Climate-appropriate packaging for destination

Shipping Documents:

Commercial invoice

Packing list

Bill of lading

Certificate of origin

AWWA compliance certificates

Test reports

Material certificates

Mechanical Joint Resilient Seated NRS Gate Valves Size Chart

.png)

.png)