Wafer Butterfly Valve with Lever Handle

Wafer Butterfly Valve with Lever Handle Definition and Components

A Wafer Butterfly Valve with Lever Handle Model No. D71X is a compact, economical, quarter-turn shut-off valve designed for general service in water, air, and other neutral media. The model number "D71X" is a common industry designation where "D" often signifies a butterfly valve, "71" indicates a wafer body with a lever-operated, resilient-seated design, and "X" denotes a rubber (elastomer) liner/seal.

Fire Butterfly Valve Key Features:

- Wafer Body:Designed to be sandwiched between two pipeline flanges using through-bolts. It is not intended to be used as an end-of-line valve or to absorb significant pipeline loads.

- Lever Handle:Provides a simple, manual 90° operation with clear visual position indication.

- Resilient Seat:An elastomer (like EPDM or NBR) is either bonded to the body or forms a sleeve, creating a tight seal against the disc.

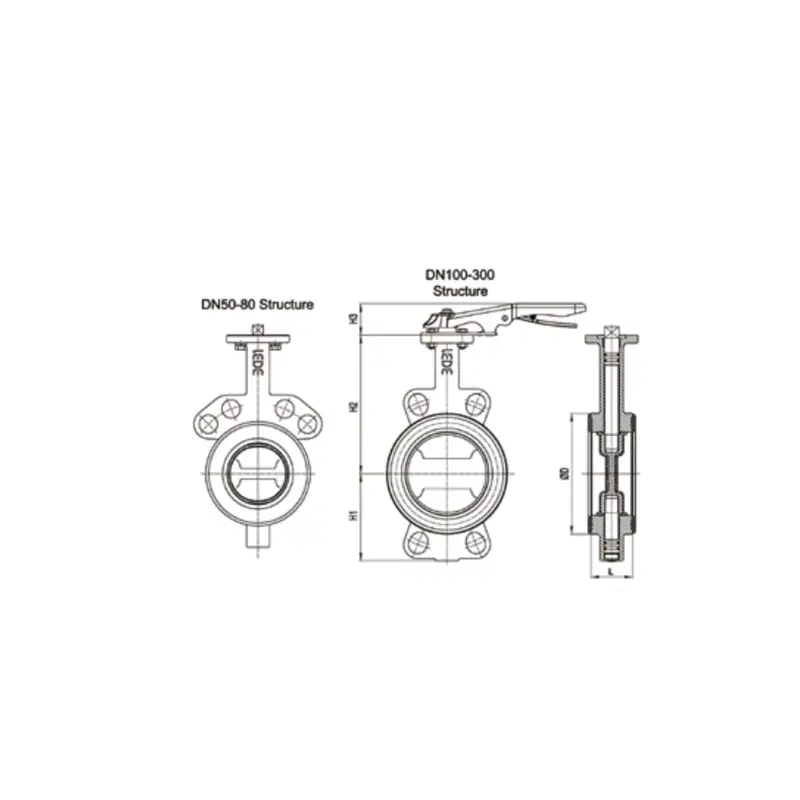

Main Parts:

- Valve Body (Wafer type, typically ductile iron or cast iron)

- Disc (The rotating closure member, often in a concentric design)

- Stem (One-piece shaft connecting disc to handle)

- Resilient Seat/Liner (Elastomer seal integrated into the valve body)

- Lever Handle (with position indicator and optional locking plate)

- Stem Seals and Bushings (Prevent leakage along the stem)

- Fasteners (Internal pins or screws securing handle to stem)

Role, Characteristics, and Application Scenarios of Wafer Butterfly Valve with Lever Handle in Pipelines

Fire Valve Functions:

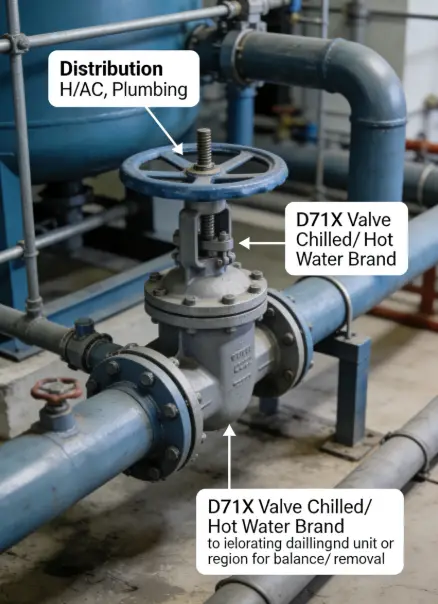

- On/Off Isolation:Basic shut-off service in low-to-medium pressure systems.

- Flow Regulation:Can be used for moderate throttling, though not as precise as a globe valve.

- Directional Service:Suitable for bidirectional flow.

Operational Features:

- Quick 90° Operation:Lever moves from fully open (parallel to pipe) to fully closed (perpendicular) in a quarter-turn.

- Visual Position Indicator:Lever clearly shows valve status.

- Compact & Lightweight:Saves space and weight compared to gate or globe valves.

- Self-Limiting Handle:Typically includes a stop to prevent over-rotation.

- Low Cost:Economical solution for basic service.

Primary Usage Scenarios:

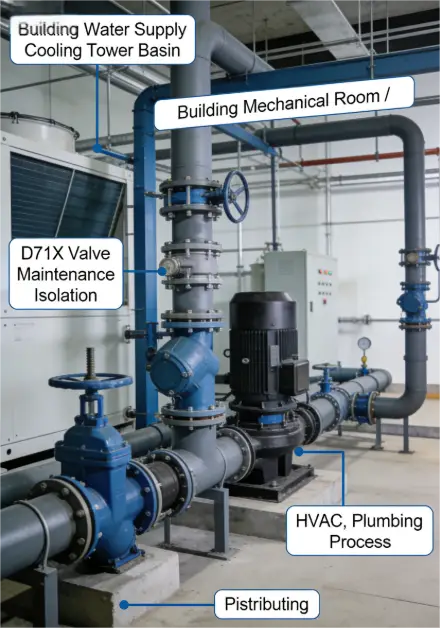

This valve is ubiquitous in commercial, institutional, and light industrial systems where cost-effectiveness and simple operation are key. It is generally NOT for critical, high-pressure, high-temperature, or fire protection services.

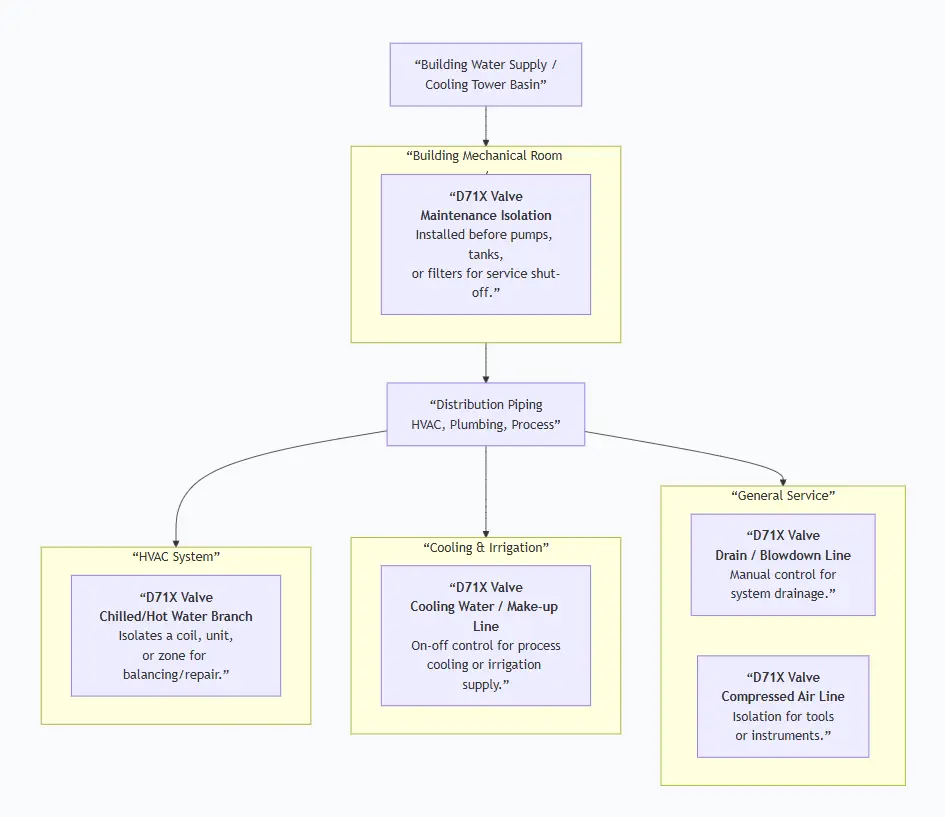

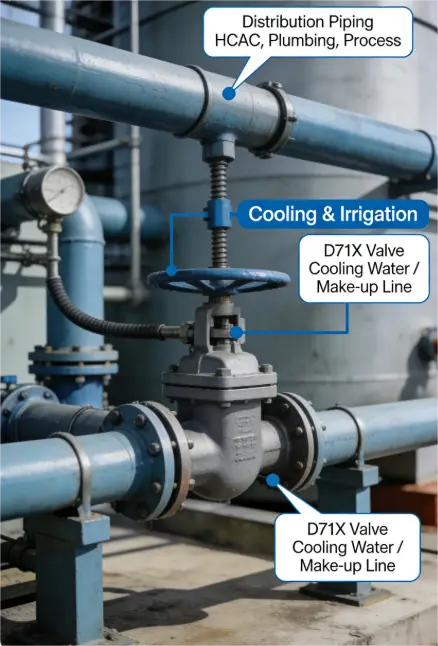

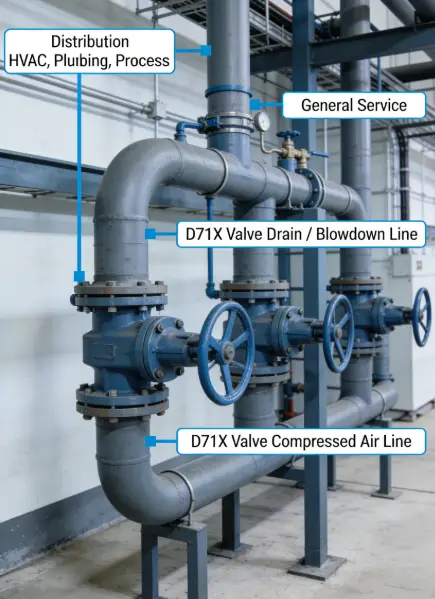

Scenario Diagram:

Wafer Butterfly Valve with Lever Handle Standards: Materials, Design, and Connections

How to Select Wafer Butterfly Valve with Lever Handle

Step 1: Define Detailed Specifications

Clarify the application to ensure the D71X is suitable.

- Media, Temperature, & Pressure:State fluid type, max temperature (e.g., 80°C for EPDM), and working pressure (e.g., 10 bar/150 psi).

- Size & Connection:Nominal Diameter (e.g., DN100) and flange standard (e.g., ANSI 150 RF).

- Materials:Specify body/disc material (e.g., Ductile Iron), seat elastomer (e.g., EPDM for water, NBR for oils), and stem material (e.g., Stainless Steel).

- Operation:Lever handle. Specify if a locking device or gear operator is needed for larger sizes (>DN200).

- Standards:Reference ISO 5752 for dimensions.

Step 2: Source and Evaluate Suppliers

- Source from general valve manufacturers or distributors. Quality can vary significantly.

- Request product data sheets confirming materials, pressure/temperature ratings, and test standards.

- For critical applications, request sample test reports or consider a lower-cost third-party inspection.

Step 3: Logistics and Documentation

- These are often bulk/stock items. Confirm lead times and MOQ (Minimum Order Quantity).

- Required docs are simpler: Commercial Invoice, Packing List, and a general Certificate of Compliance. MTRs may not be standard but can be requested.

Pre-Shipment Inspection for Export Wafer Butterfly Valve with Lever Handle and Key Considerations

Fire Protection Butterfly Valves Inspection Checklist:

Key Precautions for Export:

- Bulk Packaging:Valves are often palletized and shrink-wrapped. Ensure they are stacked securely to prevent crushing. Use corner protectors on pallets.

- Rust Prevention:For carbon steel stems or bare iron surfaces, ensure a light anti-rust oil is applied, especially for sea freight.

- Handle Protection:The protruding lever handle is vulnerable. Ensure packaging design prevents lateral impacts that could bend the handle or stem.

- Simple Documentation:Include clear packing lists inside a waterproof pouch on the pallet. For mixed shipments, mark boxes clearly by size and model.

Wafer Butterfly Valve with Lever Handle Size Chart

.png)

.png)