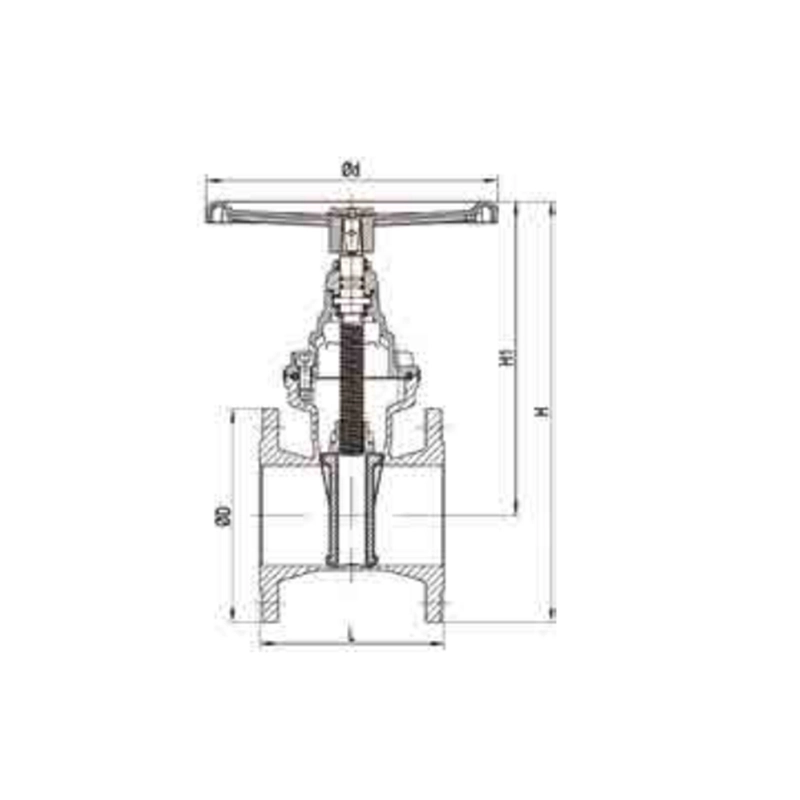

Flanged Resilient Seated NRS Gate Valve

Flanged Resilient Seated NRS Gate Valve Definition and Components

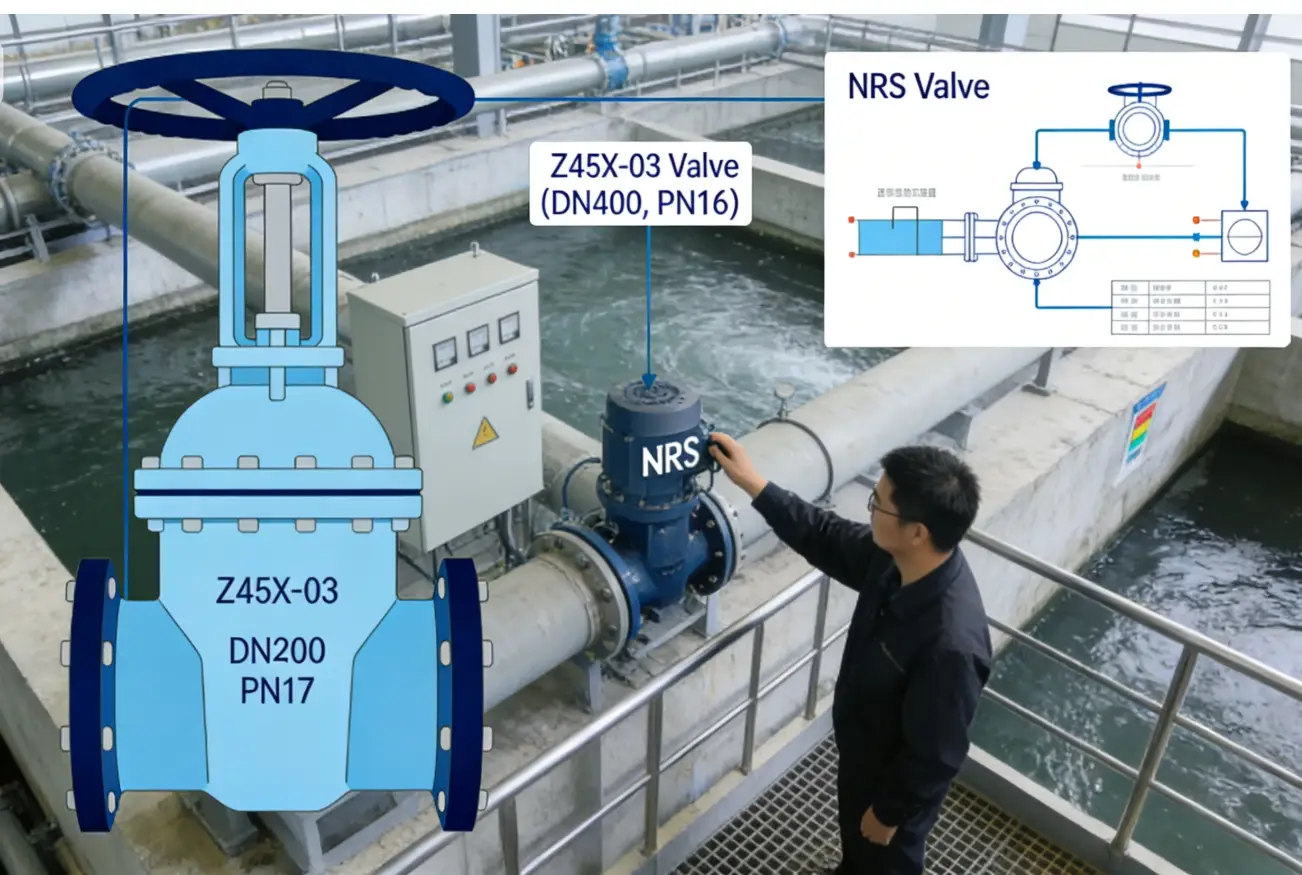

A Flanged Resilient Seated NRS Gate Valve Model No.Z45X-03 is an industrial Ductile Iron ul/fm Flanged NRS Gate Valve with flanged connections,a resilient(rubber)seat for tight sealing,and a Non-Rising Stem(NRS).The model number"Z45X-03"is a manufacturer's code where Z=Gate Valve,45=Flanged,X=Resilient Seated,03=Design Variant(often indicating a specific pressure class or feature set).

Main Parts:

Valve Body:Main pressure-containing housing with integral flanges.

Bonnet:Bolted cover that houses the stem assembly.

Gate/Disc:The moving part that blocks flow,typically with a full rubber encapsulation.

Resilient Seat:An elastomeric(e.g.,EPDM,NBR)ring against which the gate seals.

Stem(Non-Rising):A threaded shaft that moves the gate up/down without itself rising.

Stem Nut&Handwheel:Mechanism to turn the stem.

Packing Box:Seals around the stem to prevent leakage.

Flanges:Machined faces for bolting to pipeline flanges.

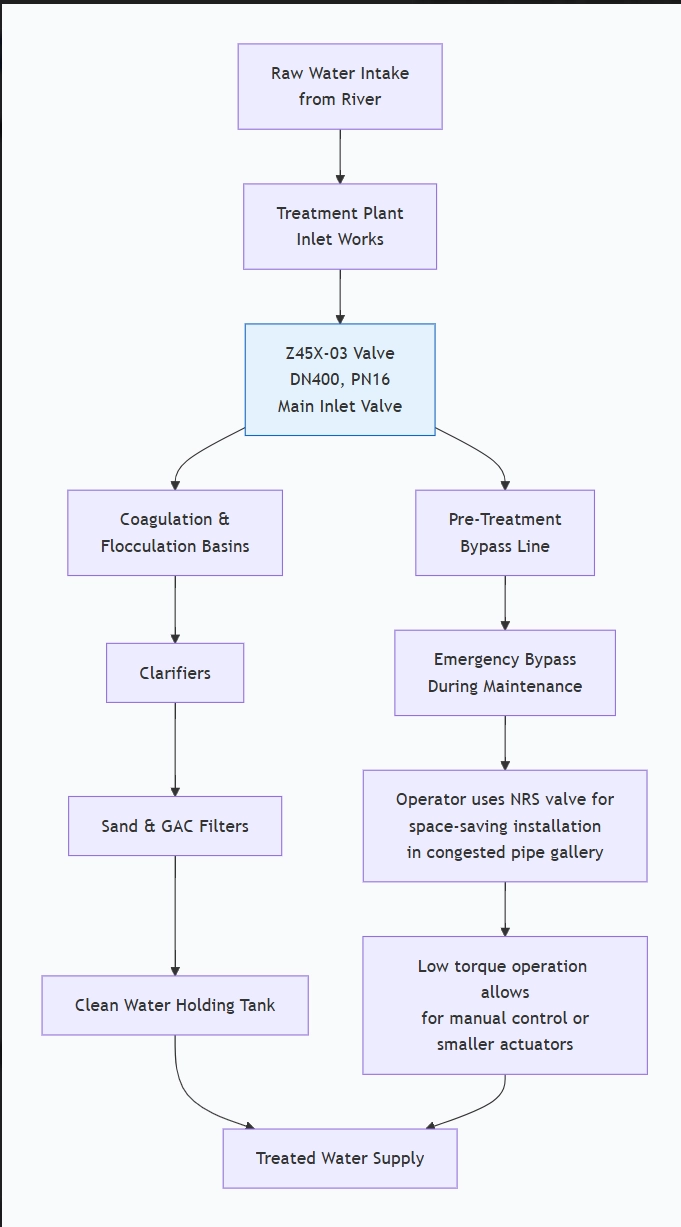

Role, Characteristics, and Application Scenarios of Flanged Resilient Seated NRS Gate Valve in Pipelines

Fire Valve Functions:

On/Off Isolation:Provides complete shut-off in pipelines.

Bidirectional Sealing:Effective seal against pressure from either flow direction.

Full Bore Flow:Minimal flow restriction when fully open.

Operational Features:

Bubble-Tight Seal:Elastic seat ensures zero leakage.

Compact Design:NRS saves vertical installation space.

Low Operating Torque:Easy to open/close.

Corrosion Resistant:Often coated internally/externally.

Maintenance-Free:No lubrication required for the seat.

Typical Applications:

Potable Water Distribution

Wastewater&Sewage Treatment Plants

Fire Protection Systems

Industrial Cooling Water Lines

General Service in Chemical&Process Industries

Scenario Diagram:

Flanged Resilient Seated NRS Gate Valve Standards: Materials, Design, and Connections

Fire gate valve Material Standards:

Body/Bonnet/Gate:Ductile Iron(e.g.,ASTM A536 Gr.65-45-12/EN-GJS-500-7).

Stem:Stainless Steel(e.g.,AISI 304,316,431).

Seat/Seals:EPDM(for water),NBR(for oils),Viton®(FKM for chemicals).

Bolting:Carbon Steel,Grade 8.8 or equivalent.

Coatings:Internal epoxy(e.g.,AWWA C550),external paint or epoxy.

Design Standards:

General:API 600,ISO 5208,MSS SP-70/80.

Waterworks:AWWA C509/C515(common for N.America).

Testing:API 598,ISO 5208(shell test 1.5x rating,seat test 1.1x rating).

Face-to-Face:ANSI B16.10,EN 558-1,ISO 5752.

Connection Standards:

Flange Standards:ANSI B16.5(Class 150/300),EN 1092-2(PN10/16/25),AS 2129.

Flange Faces:Raised Face(RF),Flat Face(FF),or RTJ.Model Z45X-03 often has RF.

Drilling:Matches chosen flange standard(e.g.,ANSI drilling for Class 150).

How to Select Such Flanged Resilient Seated NRS Gate Valve

Define Specifications:

Size(DN/NPS)and Pressure Rating(PN/Class).

Material Grades for body,stem,seat.

Connection Details:Exact flange standard,facing,drilling.

Operational:Manual handwheel,gear operator,or actuator requirements.

Standards Compliance:Specify required design standards(e.g.,"to API 600").

Supplier Identification:

Source from established valve manufacturers or authorized distributors.

Verify quality certifications(ISO 9001).

Request Quotation(RFQ):

Provide a clear technical data sheet.

Request compliance certificates,material test reports,and drawings.

Evaluation&Order:

Compare technical compliance,lead time,and commercial terms.

Issue a Purchase Order referencing all specifications.

Documentation Review:

Approve manufacturing drawings and test procedures from the supplier.

Pre-Shipment Inspection for Export Flanged Resilient Seated NRS Gate Valveand Key Considerations

Inspection Protocol:

Documentation Review: Verify Material Test Reports, Certificate of Compliance, and test procedures.

Visual & Dimensional Check:

No surface defects.

Flange dimensions (thickness, O.D., bolt circle, hole size) per standard.

Face-to-face length correct.

Permanent marking present (size, pressure, material, brand).

Pressure Testing (Witnessed):

Shell Test: Typically at 1.5 x rated pressure. No leakage permitted.

Seat Leakage Test: Typically at 1.1 x rated pressure in both directions. Allowable leakage is "zero" for resilient seated valves.

Operational Check: Handwheel turns smoothly, gate moves fully open/closed.

Export Precautions:

Packaging:

Flange faces MUST be protected with sturdy, bolt-on plastic/metal covers.

Internal cavity should be dry, with Vapor Corrosion Inhibitor (VCI) bags.

Valves securely crated on wooden pallets/skids.

Documentation for Customs:

Accurate Packing List and Commercial Invoice.

Ensure all certificates (MTRs, test reports) are original or certified copies ready for the consignee.

.png)

.png)